4

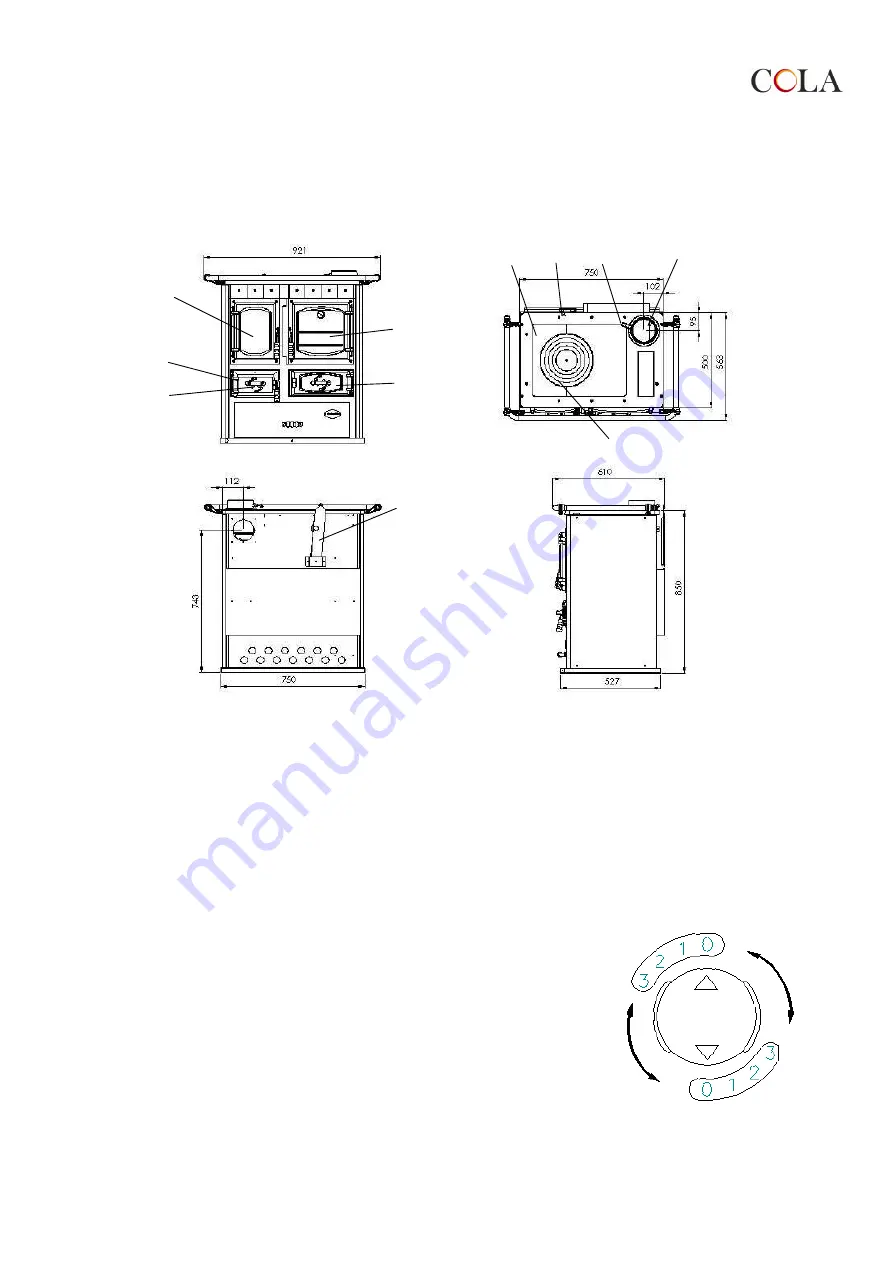

Mini Johanna

A

D

B

C

F

E

Anello fumi Ø 120mm

Diametro max 270mm

Fig 1 Mini Johanna dimensions

F

G

H

1.3.1 Fire door (A)

The fire door is opened by pulling the handle outwards; use the protective glove supplied with the stove when the

handle is hot. There are air inlet slots around the top and bottom edges of the fire door to keep the glass clean.

1.3.2 Ash door (B)

The ash door is opened by pulling the handle outwards, to access a compartment with a removable ash pan inside.

1.3.4 Baffle inspection door (D)

This door gives access to the baffle located under the oven for cleaning.

Fig.2 Primary air control

1.3.3 Primary air control (C)

By means of the revolving air control on the ash door the primary air can flow into

the lower part of the stove through the ash pan and grate. The primary air is

necessary for the combustion process, therefore make sure to empty the ash pan

regularly so that the ash cannot obstruct the combustion air inlet. When the arrow

is in position 0, the air inlet is closed; when the arrow is in position 3, the air inlet is

fully open.

Warning: Wider adjustments can cause overheating and damage to the stove