SYMBOL GLOSS

23

OM.SS60.20141016

APPENDIX B: TRANSFORMER

CONFIGURATION

IN THIS SECTION

High Voltage Connection . . . . . . . . . . . 23

Normal / Medium Voltage Connection. . . . . . 24

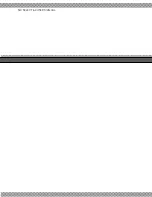

HIGH VOLTAGE CONNECTION:

If the incoming voltage is between 118 – 140 VAC

OR

between 240 – 285 VAC, the transformer

should be configured as shown below:

•

Wire #43 (white) should be connected to wire #55 (white/yellow), and

•

Wire #44 (white/brown) should be connected to wire #11 (yellow)

Summary of Contents for SDI Select 60

Page 3: ...OM SS60 20141016 ...

Page 4: ...OM SS60 20141016 ...

Page 6: ......

Page 26: ......

Page 36: ...SDI SELECT 60 USER MANUAL ...

Page 38: ...SDI SELECT 60 USER MANUAL ...

Page 40: ...SDI SELECT 60 USER MANUAL ...

Page 41: ...TRAINING VIDEO ...

Page 42: ...SDI SELECT 60 USER MANUAL ...