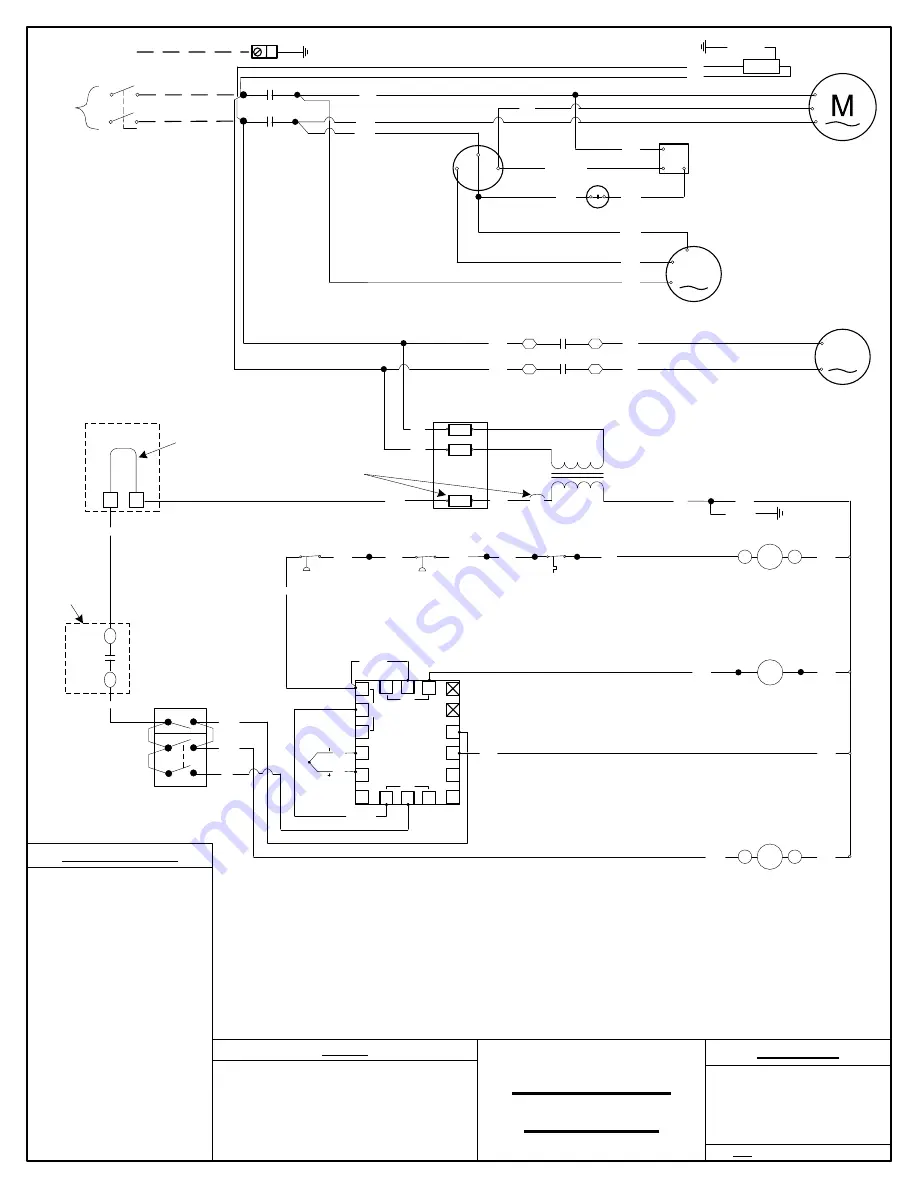

FILE: ACWC-024-E-_-_-_-2 Units.vsd

DESCRIPTION

COLD SHOT

CHILLERS

NOTES:

208/230V

460V

CT

CONNECT FOR

APPROPRIATE

VOLTAGE

“NOTE”

24V

secondary

YEL

(COM)

CB

BRN

GRN/YEL

GND

BLU

RED

FU

5 AMP

BLK

BLK

FU

FU

FB-1

(2)-1 AMP

Fuse may be

used in place of

circuit breaker

FUSES

TB1

Remove jumper for remote on/off

connect TB1 #1 and TB1 #2 to a

“DRY” non-voltage terminals

WITH REMOTE

ON/OFF ONLY

2

1

TB1

YEL

BLU

OPEN 10 PSI

CLOSE 25

OPEN 630 PSI

CLOSE 480

HPS

LPS

YEL

BLU

YEL

YEL

BRN

GRN

17

3

4

6

5

1

2

7

8

9

10

11

12

16

18

15

14

13

L

N

TOP

O/P2

O/P3

O/

P

1

24V

RED

WHT

TC

Chromalox

6040

SW

YEL

GRN

GRN

Pump Only

Cooling Cycle

RED

RED

ICM491

4

6

COM

RUN

WITH ICM

ONLY

JUMPER

BRN

CC

C1

C2

PC

C1

C2

BRN

BRN

WIRING SCHEMATIC FOR

ACWC-024-E-_-_-40-2

ACWC-024-E-_-_-IND-2

GND

L1

L3

TO

POWER

SUPPLY

GROUNDING LUG

PC

BLK

BLK

BLK

BLK

DISCONNECT

FIELD

SUPPLIED

BRN

L3

L1

T3

T1

SC

BLK

RED

RED

VIO

ORN

COMPRESSOR

C

S

R

CH

BLK

BLK

GRN/YEL

GND

CC

HERM

COM

FAN

RED

DRC

1

5

2

BLK

STRIPED

PR

M

FAN MOTOR

M

CHILLER PUMP

ORN

(see note #4)

WHT

BRN

HGB

COMPONENT CODE

CB

CIRCUIT BREAKER

CC

COMPRESSOR CONTACTOR

CH

CRANKCASE HEATER

COM

COMMON

CT

CONTROL TRANSFORMER

DRC

DUAL RUN CAPACITOR

FB

FUSE BLOCK

FCC

FAN CYCLE CONTROL

FS

FLOW SAFETY

FU

FUSE

GND

GROUND

HGB

HOT GAS BYPASS

HGR

HOT GAS RELAY

HPS

HIGH PRESSURE SAFETY

ICM

VOLTAGE MONITOR

L

LINE

LPS

LOW PRESSURE SAFETY

M

MOTOR

OPT

OPTIONAL

PC

PUMP CONTACTOR

PR

POTENTIAL RELAY

RC

RUN CAPACITOR

SC

START CAPACITOR

SW

CHILLER ON/OFF SWITCH

TB

TERMINAL BLOCK

TC

THERMOCOUPLE TYPE-J

1. REPLACEMENT WIRE AND FUSES MUST BE THE SAME

SIZE AS ORIGINAL.

2. UNIT MUST BE PERMANENTLY GROUNDED AND

CONFORM TO N.E.C. & LOCAL CODES.

3. MINIMUM WIRE SIZE BASED ON 75 DEGREES C

INSULATION COPPER WIRE.

4. OPTIONAL HOT GAS BYPASS FOR CAPACITY CONTROL.

JUMPER

OPEN 35 DEG.

MANUAL RESET

FS

BLK