MNL_Standard-NoSpecs_ACWC-18to240-E-_(0713).docx

- 6 -

5.

IMPORTANT: Allowing the unit to operate with a voltage imbalance in excess of 2% may void the warranty.

% Voltage Imbalance = 100 x (max voltage deviation from avg voltage) / (average voltage)

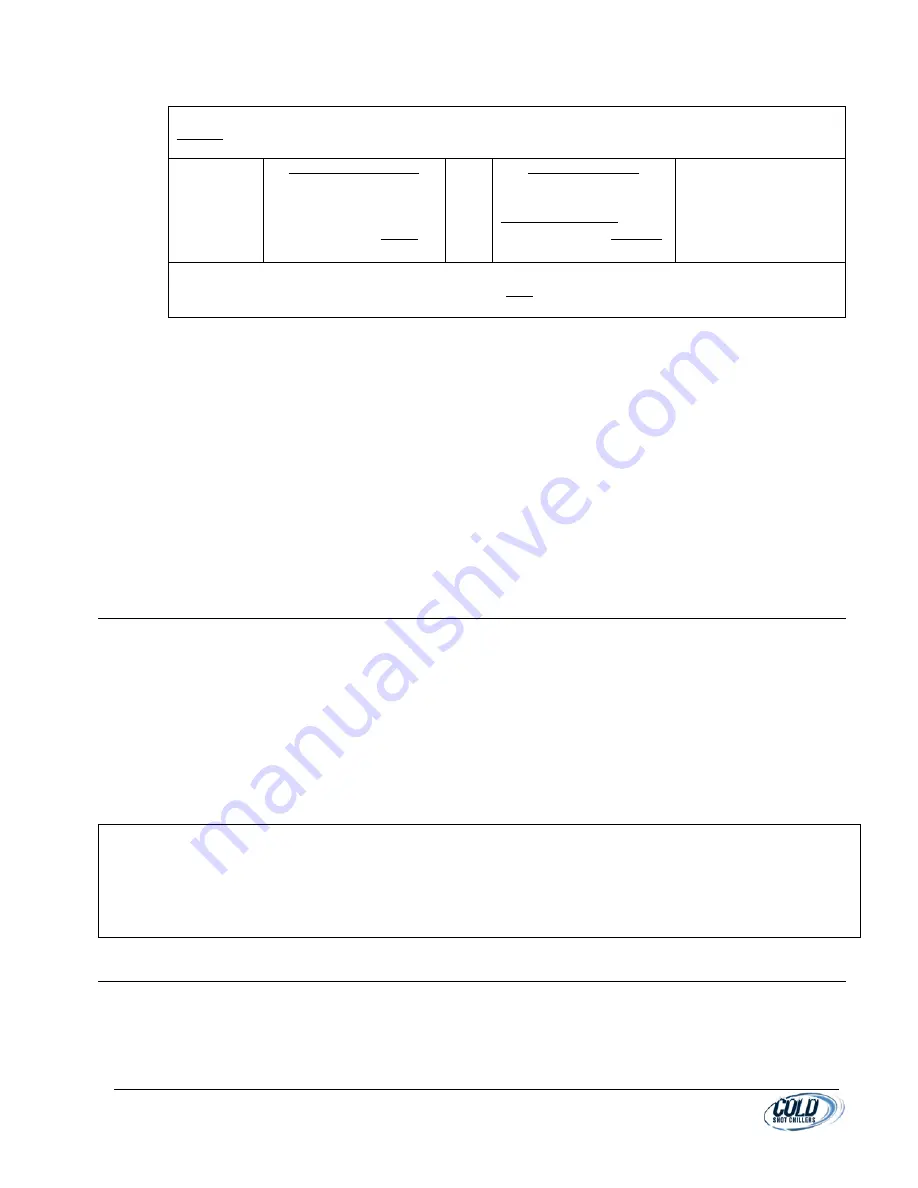

Example: Expected supply voltage to unit is 240-3-60.

Determine maximum deviation from average voltage:

MAXIMUM DEVIATION:

AB = 243

A

– 239

B

= 4 volts*

AC = 239

A

– 238

C

= 1 volt

BC = 239

B

– 236

C

= 3 volts

*MAX DEVIATION =

4 volts

AVERAGE VOLTAGE:

AB = 243 volts

BC = 236 volts

AC = 238 volts

AVERAGE = 717/3 =

239 volts

•

Determine % voltage imbalance:

%Voltage Imbalance = 100 x

4

/

239

= 1.7%

•

This amount of phase imbalance is Satisfactory as it is below the maximum allowable 2%.

6.

UNBALANCED 3-PHASE SUPPLY VOLTAGE:

a)

Never operate a system where a phase imbalance in supply voltage is greater than 2%. Excess operation

with voltage outside of tolerance (for example “Brown Outs” will result in motor damage. (This is

considered abuse and is not covered under Warranty).

b)

If Voltage Imbalance Greater than 2%:

(1)

If the supply voltage phase imbalance is more than 2%, contact your local electric utility company

immediately.

(2)

Check the voltage at the individual components such as each compressor and pump when

operating.

(3)

A voltage imbalance may be an indication of loose wires/cable connections or faulty contactors.

(4)

Another issue may be the components themselves. Troubleshoot if needed.

7.

Verify that the crankcase heaters are warming properly by using a thermometer or by carefully placing back of

hand near the base of the compressor by the heater.

F.

FREEZE PROTECTION

1.

Protection of system components from freezing is of the utmost concern. Freezing can occur from the external

ambient or internal system temperatures.

2.

INTERNAL: The evaporator (or other heat exchanger) is the primary component that is susceptible to freezing

even during normal operation. The refrigerant side commonly operates at 8 to 12 degrees below the

temperature of the chilled fluid temperature. The fluid entering the evaporator must be capable of passing

through without forming ice. Ice formation can quickly restrict the flow causing further freezing and eventually

expansion of internals resulting in rupture. Attention must be made towards any process involving the

evaporator. The chilled fluid characteristics need to have a freeze point that is well below any temperature that

the chiller is capable of cooling. (See Glycol)

3.

The chiller is equipped with various safety devices designed and set to assist with protecting the system from

hazards.

G.

GLYCOL

1.

Glycol and water mixtures are common methods to change a fluid’s freezing point but may reduce the cooling

performance of the chiller. Use of any glycol or other additives to the fluid should be carefully considered.

Follow the glycol manufacturer or supplier’s directions for system preparation, mixtures, disposal, and

maintenance of concentrations.

IMPORTANT!!

DO NOT BYPASS OR ADJUST ANY SAFETY DEVICES OR PARAMETERS WITHOUT

FIRST CONTACTING COLD SHOT CHILLERS.

ANY MODIFICATIONS OF THE CHILLER SYSTEM FROM THE MANUFACTURER’S DESIGN WILL REQUIRE PRIOR

WRITTEN APPROVAL FROM COLD SHOT CHILLER’S, OTHERWISE ALL WARRANTIES WILL BECOME VOID.