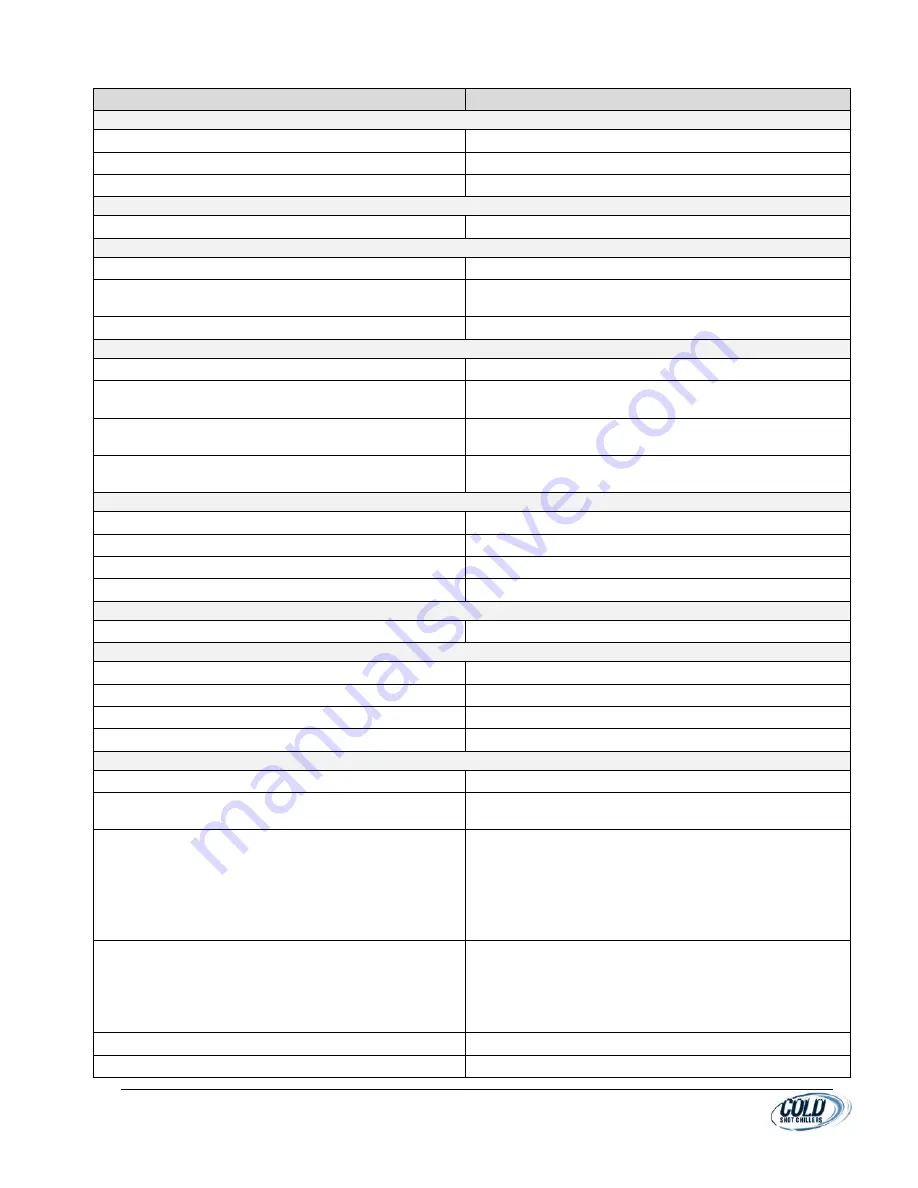

SYMPTOM AND PROBABLE CAUSE

PROBABLE REMEDY

UNIT OPERATES TOO LONG OR CONTINUOUSLY

9.

Low refrigerant charge.

9.

Add refrigerant.

10.

Control contacts fused.

10.

Replace control.

11.

Air in system.

11.

Purge and evacuate system.

SYSTEM IS NOISY

1.

Piping vibration.

1.

Support piping as required.

COMPRESSOR LOSES OIL

1.

Leak in system.

1.

Repair leak.

2.

Crankcase heaters not energized during

shutdown.

2.

Check wiring and relays. Check heater and replace

if defective. (Some heaters are always on.)

3.

Improper interconnecting piping design.

3.

Check piping for oil return. Replace if necessary.

FROSTED SUCTION LINE

1.

Expansion valve not operating properly.

1.

Adjust expansion valve.

2.

Low temperature operation.

2.

Verify low temperature operation is proper, verify

superheat.

3.

Low refrigerant.

3.

Determine cause of low refrigerant. Add

refrigerant.

4.

Low fluid flow.

4.

Verify fluid flow. Clean strainer and bypass is

throttled to maintain 3gpm/ton.

HOT LIQUID LINE

1.

Dirty condenser coil.

1.

Clean condenser coil.

2.

Expansion valve malfunctioning.

2.

Verify Charge and adjust expansion valve.

3.

Shortage of refrigerant due to leak.

3.

Repair leak and recharge.

4.

Overcharged system.

4.

Remove refrigerant, adjust charge.

FROSTED LIQUID LINE AFTER DRIER

1.

Restricted filter drier.

1.

Remove restriction or replace.

COMPRESSOR WILL NOT LOAD/UNLOAD – HOT GAS VALVE OPERATION

1.

Defective Hot Gas Bypass valve.

1.

Replace valve/solenoid.

2.

Defective Capacity Control solenoid/valve.

2.

Replace valve/solenoid.

3.

Weak, broken, or wrong valve body spring.

3.

Replace spring.

4.

Program (PLC) not sending signal to solenoid.

4.

Verify PLC signal and wiring.

PUMP WILL NOT RUN

1.

No Control Circuit Power.

1.

Replace Fuse or reset control circuit breaker.

2.

No Power to Contactor.

2.

Replace Fuse or reset

main

circuit

breaker/disconnect.

3.

Low Line Voltage.

3.

Check line voltage — determine location of voltage

drop and remedy deficiency.

-

Excess operation with voltage outside of

tolerance (for example “Brown Outs” will

result in motor damage. (This is considered

abuse and is not covered under Warranty).

4.

Contactor stuck open.

4.

Verify control voltage to contactor.

-

No Voltage – find cause of no voltage.

-

Low Voltage - determine location of voltage

drop and remedy.

-

Replace contactor.

5.

Loose terminal connection.

5.

Check connections. Clamp on insulation material.

6.

Improperly wired remote controls.

6.

Verify wiring, and rewire as needed.

MNL_Standard-Basic_ACWC-24to240-E-(IN PROGRESS)_(0815).docx

- 16 -

Summary of Contents for ACWC-180-EM-DR-LT-0-5

Page 35: ...Notes...