Marrone & Co., Inc.

2730 Maximilian Drive • Houston, Texas 77032 • Phone (281) 227-8400 • (800) 473-9178

Fax (281) 227-8404 • www.waterchillers.com

Guide_DeltaPLC-ProgramOperations-A1_020816.docx

IMPORTANT! Continuous restarting of the system with a fault is considered abuse and will void all warranties.

The Temperature Controller has additional normally open contacts available that will close during an alarm situation.

-

Alarm Output 1 indicates that the Process temperature has exceeded the allowable temperature range limits.

-

Alarm Output 2 indicates that the Process temperature has exceeded the allowable temperature limits.

-

Alarm Output 3 indicates that the Process temperature has deviated from the set value by the deviation high or low

values.

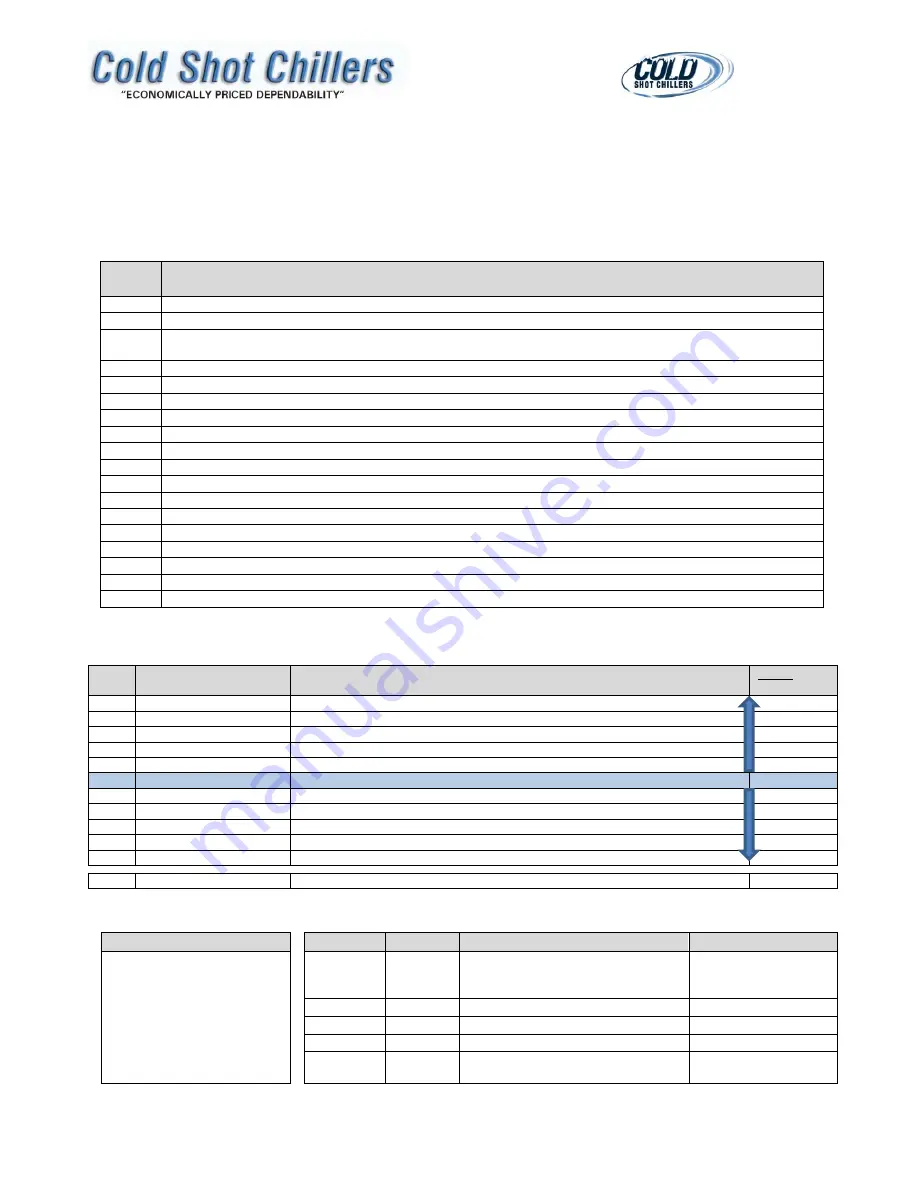

FAULT CODE LIST

FAULT

CODE

DESCRIPTION

9 0 0 0

Only shown if there are no settings in the DTB Temperature Controller

9 1 0 0

Set Value Temperature Outside the Permitted Range (Will reset the nearest range temperature limit)

9 1 1 0

Process Value has Deviated Higher Than Set Value Limit without lowering within time period (approx 30 minutes). If this occurs

and the cause is known, then raise the SV to be closer to the PV to permit recirculating system.

9 1 2 0

Process Value Temperature Too High

9 2 0 0

Refrigerant Pressure Too High at Startup (High Pressure Switch is open) – If manual switch, then press reset.

9 2 1 0

Refrigerant Pressure Too High during Operation (High Pressure Switch is open) – If manual switch, then press reset.

9 3 0 0

Refrigerant Pressure Low at Startup or During Pump Operation (Low Pressure Switch is open)

9 3 1 0

Refrigerant Pressure Low during Compressor Operation after Initial Compressor Start Bypass Timer

9 4 0 0

No Fluid Flow. Flow was not established in the initial time period (typically 5 seconds)

9 4 1 0

Fluid Flow Loss for more than time period or Excessive Cycling of Flow Switch within time period

9 5 0 0

Refrigerant Suction Temperature Low (Flow Safety Thermostat is open.) Possibly due to inconsistent flow

9 5 1 0

Refrigerant Suction Thermostat Open at Startup (Suction Temperature Low)

9 6 0 0

Leaving Fluid Temperature Too Low (Freeze Thermostat is open)

9 7 0 0

Either: 1) Pump Safety Circuit has tripped or 2) Low Tank Level at Start

9 7 1 0

Either: 1) Pump Safety circuit was tripped or 2) Low Tank Level or Excessive Cycling of Tank Level Switch

9 8 0 0

Loss of Communications in Pump Mode (Typically, turn switch off and back on to re-establish communication)

9 8 1 0

Loss of Communications between Temperature Controller and PLC

9 8 2 0

Loss of Communications between Temperature Controller and Temperature Sensor/Thermocouple

If further assistance is needed regarding the Contact Cold Shot Chillers with any concerns or issues, as needed.

Example of Temperatures of Operation

Code

Description

Detail

Typical Values

(°F)

TLH

Temperature Limit High

The highest temperature at which all functions will stop.

120

DTH

Deviation Temperature High

Difference above Set Value that a timer starts. If temperature does not lower, then fault.

SP + Δ30=85

RH

Range High

Highest value that can be entered as a Set Value

80

DU2

Deviation Upper 2

Hysteresis value above Set Value plus 1°F

58

DU1

Deviation Upper 1

Hysteresis value above Set Value

57

SV

Setpoint Value

The desired temperature entered in the controller

55

DL1

Deviation Lower 1

Half of the hysteresis value below Set Value

54

DL2

Deviation Lower 2

Hysteresis value below Set Value

53

RL

Range Low

Lowest value that can be entered as a Set Value

44

DTL

Deviation Temperature Low

Deviated temperature value below Set Value which resets all cooling functions.

SP - Δ7=48

TLL

Temperature Limit Low

Lowest temperature which resets all cooling functions.

37

CTS

Cooling Hysteresis

The number of degrees from Set Value that cooling operations start and stop.

SP Δ 2

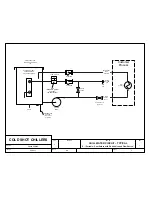

Communication Option via PLC RS-232 Communication

Via DVP14SS2 COM1 port

Register

Address

Description

Function

Com1 Port: RS-232

PLC Modbus address: 1

Data Length: 7 bit

Stop bits: 1

Parity: Even

Baud rate: 9600

D0

(Machine

mode)

1000hex

1 is Cooling Cycle mode.

2 is Pump Only mode.

3 is Off (selector switch is in OFF position).

Selector Switch Position

D1

1001 hex

SV

Set Value

D2

1002 hex

PV

Process Value

D3

1003 hex

Fault#

Fault #

D4

1004 hex

1 is Cooling Mode Status – OK

0 is Cooling Mode Status – Not Active

Cooling Mode Status

Summary of Contents for ACWC-180-EM-DR-LT-0-5

Page 35: ...Notes...