9

The following is an explanation of the control panel controls:

1) BEATER MOTOR STARTER - activates the beater/auger

drive motor. In the "BEATER" mode, the starter is energized by

the front switch pad. In the "AUTO" mode, the starter is activated

by either the proximity switch or timer.

2) COMPRESSOR CONTACTOR - activates the refrigeration

compressor. When the unit is in the "AUTO" mode, the compressor

contactor can be energized by the electronic H.O.M., timer, or

"TEV" thermostat. In the "ENERGY CONS." mode, the contactor

will be energized by the electronic board.

3) The OVERLOAD PROTECTOR senses the current supplied

to the beater motor and will stop the entire machine in the event

of an overload. This device also houses the overload reset

mechanism.

4) The main TRANSFORMER steps down the line voltage (115

Volts) to 24 Volts for the control circuit.

5) ELECTRONIC BOARD - controls all the functions of the

machine.

- Temperature of the product in hopper.

- Consistency of the product.

- Timer.

- In stand-by controls temperature of the product in hopper and

cylinder.

- Controls and or energizes all the information or messages

displayed on the monitor.

6) FUSE - protects 115 voltage line.

7) The CURRENT TRANSFORMER monitors beater motor

current for the electronic H.O.M.

8) TRANSFORMER - Steps down the 24 volt line to 11 volts for

the electronic board.

9) The 24 volt TERMINAL BLOCK serves as the inter-connection

point for all 24 volt controlling circuit components.

F) OTHER CONTROLS

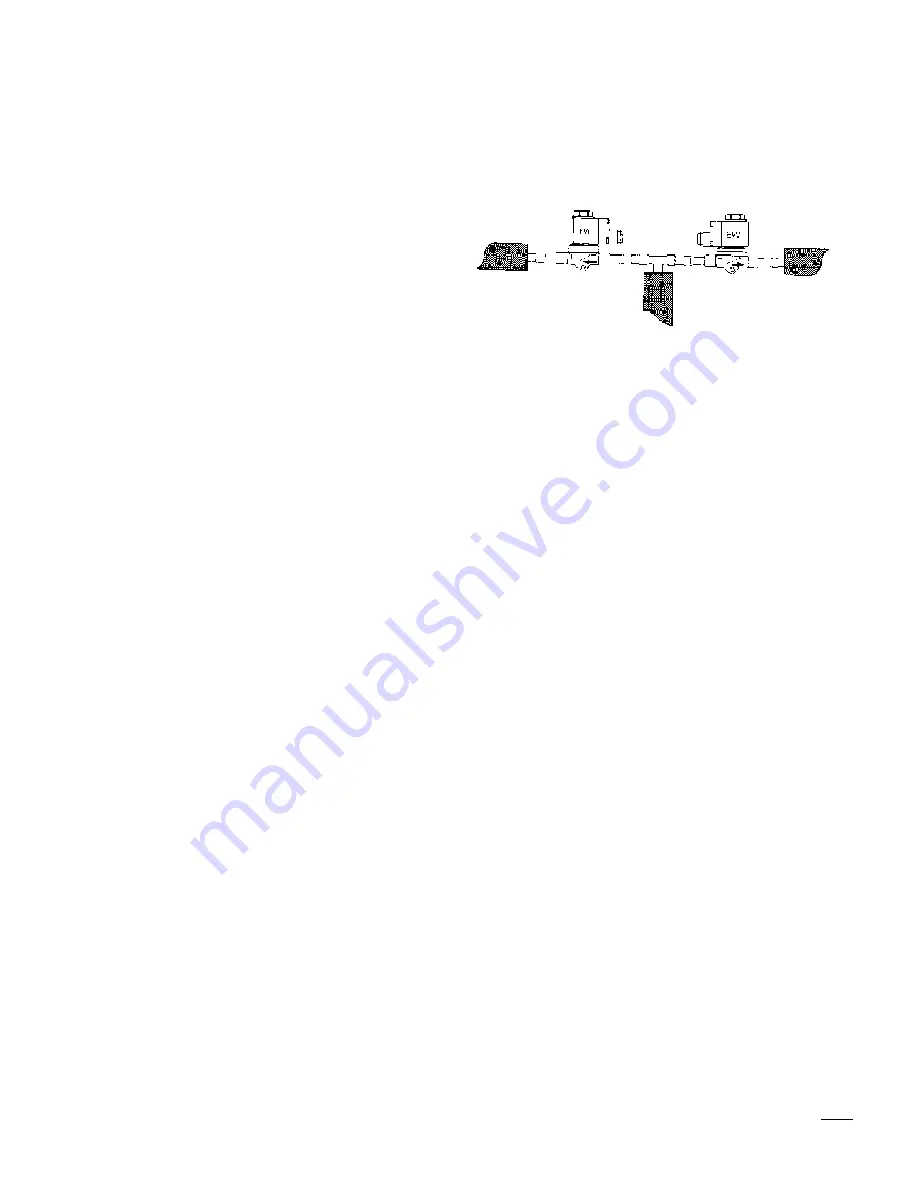

1) Refrigeration SOLENOID VALVES are located behind the left

side panel. These valves are normally closed and when energized

by the electronic board, direct refrigerant flow to either the

freezing cylinder or mix tank. The mix tank solenoid is identified

as "EVV" and the cylinder solenoid as "EVC".

2) The HIGH PRESSURE CUT-OUT is located on the right side

of the freezer and is tied into discharge or high side line near the

compressor. In the event of high pressure situation, it will shut

down the compressor. Reset is automatic when the high pressure

subsides. Common causes for cut-out or shut down arerestricted

air flow on air cooled models, unusually high ambient (room)

temperatures, and restricted or excessively hot water flow on

water cooled models.