22

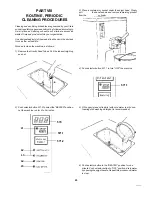

5) When this function is on, pilot light L2 lit, the product is cooled

down until it reaches the proper consistency according to the

HOM calibration.

During this function the monitor displays a number indicating

the consistency of the product in the cylinder until it reaches

the set value, then indicates the temperature of mix in the

hopper.

Initial freeze-down will take 7-10 minutes depending on the

type of mix used.

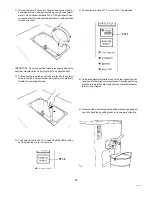

HOM ADJUSTMENT (AUTOMATIC)

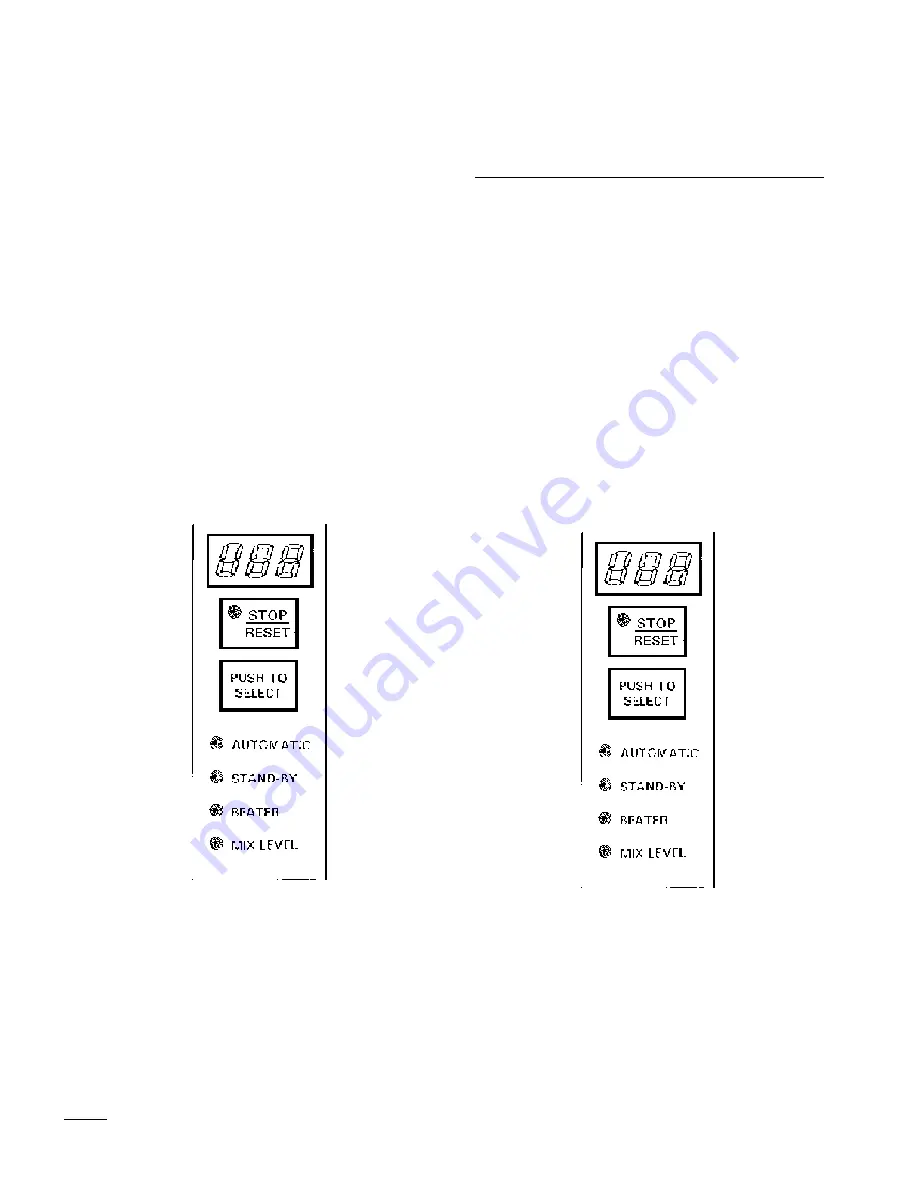

Push “STOP” and hold, then push “PUSH TO SELECT” button for

3 seconds; the display will show “St1” and then the programmed

value of the HOM. Release button.

Normally the HOM is set to 10. The regulation can vary from 3 to

10 by pushing on the “Push to Select” button. Once the HOM is

set to the desired value, do not push the button again, the display

will flash 3 times and then returns to the normal functioning mode.

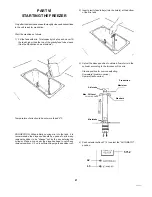

MIX TANK REFRIGERATION

The mix tank is provided with a time controlled refrigerated

system. Every two (2) minutes the refrigeration system is energized

and runs for 25 seconds when above 60° F.

Below 60° F the refrigeration system is energized and runs for

25 sec. every 4 minutes.

Mix in the tank should have a final temperature between 38/44°F.

MIX TANK TEMPERATURE REGULATION

NOTE: The 38/44°F Holding Temperature is fixed in the control

board memory.

After periodically taking the mix temperature in the tank and

observing the monitor displayed temperature, it may be necessary

to adjust the monitor setting to display matching values.

Remember the actual mix temperature must be 38/44°F.

If the temperature indicated by the display is not equal to the

temperature of the mix in the tank, push “STOP” and hold, then

push “PUSH TO SELECT” button for 3 seconds.

Push the “STOP” button one more time. “oFS” will be displayed

and then temperature value °F:

If the temperature indicated by the display is not equal to the

temperature of the mix in the tank, press the “PUSH TO SELECT”

until the displayed and actual value match.

NOTE: MACHINES WITH REAR ELECTRIC BOX