24

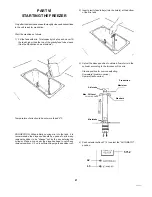

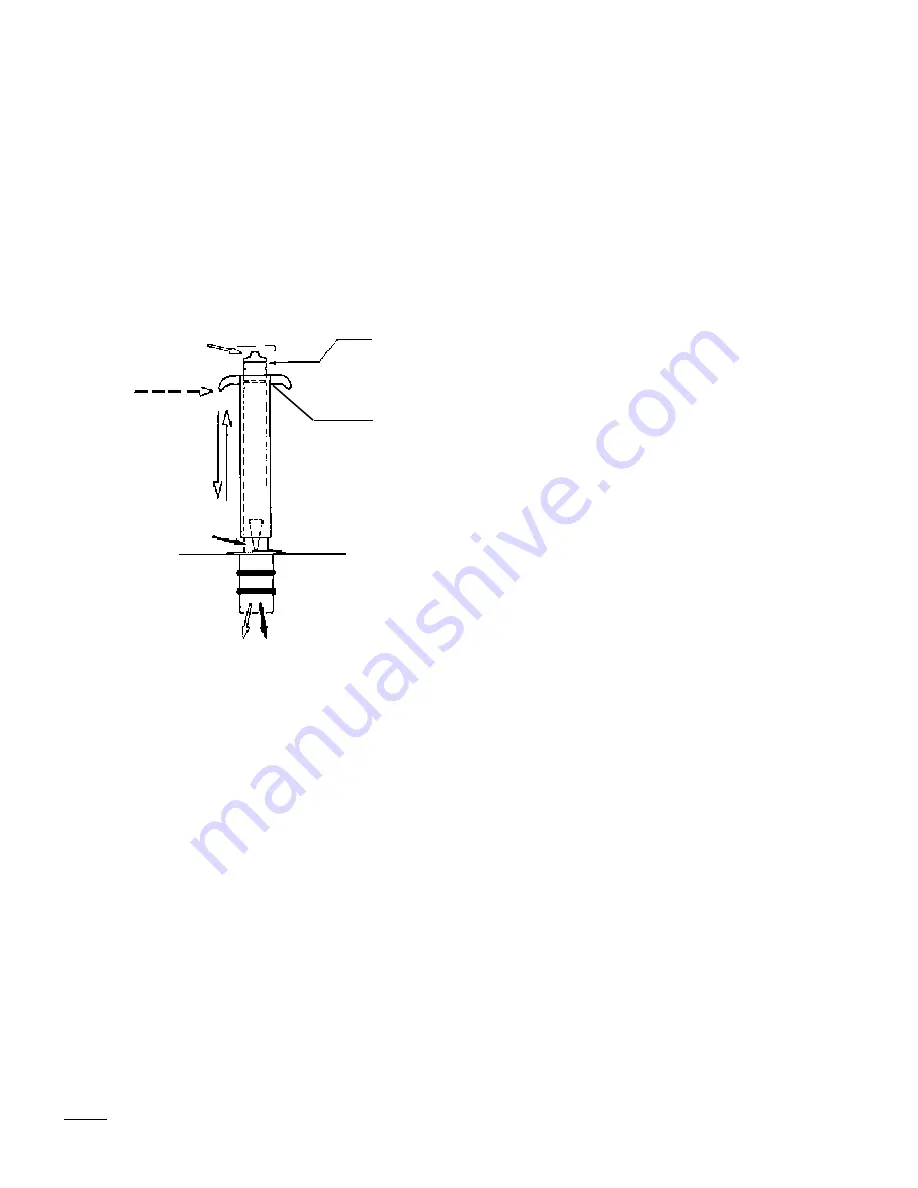

GRAVITY FEED VALVE - HOW TO OPERATE

AND MAKE ADJUSTMENTS

The Gravity Feed Valve consists of two tubes, one sliding inside

the other, and a plunger/splash guard.

The inner tube blends the flow of air and mix into the freezing

cylinder. Air enters through the top of the tube and the mix,

through a triangular hole at the base. See illustration below.

The outer tube is actually a valve. Lifting the outer tube varies the

size of the hole and the amount of mix that flows into the freezing

cylinder. The size of the air inlet, at the top of the tube, does not

change so the amount of air that enters the freezing cylinder is

constant.

You can vary the overrun (yield) by letting more or less mix enter

the freezing cylinder by manually regulating the valve.

The plunger/splash guard keeps the mix. from splashing on the

mix tank cover and serves as a device to eliminate potential

clogging inside the tubes.

You may find it necessary to adjust the position of the outer tube

in order to regulate the amount of mix entering the freezing

cylinder after start-up. Actually, sales conditions will dictate the

proper adjustment.

If more production is required, increase the opening by lifting the

outer tube, and conversely when business is slow, push down

the outer tube, reducing the opening. Naturally, when the mix

runs low in the mix tank, you will open the slot more and

eventually take the feed tube out completely to use the last of mix

in the mix tank.

Mix Intake

Max. Fill Level

Air Intake

Production

Maximum

Standard