26

IMPORTANT: Operate unit only in the BEATER position when

cleaning. Do not operate unit for excessive periods in the

BEATER position, one minute intervals per rinse is recommended.

7) Brush all surface areas, with brushes provided, to remove all

mix particles.

8) Drain water:

9) Refer to Part III, “Initial Cleaning Procedure” of this manual

to continue the cleaning, disassembly, re-assembly, and

start-up procedures.

PART IX

TECHNICAL INFORMATION

152

UC 511

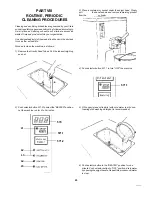

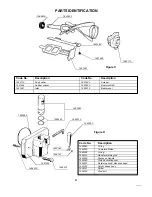

A) Refrigeration- Ice Cream Cylinder Expansion Valve

Compressor - Hermetic -

FLA - Amperage - 9 A

Suction Pressure -19/20 lbs

Discharge Pressure - 230/250

Cooling System - Air

Use R 502 only - 23 oz = 650 gr

Refrigeration - Mix Tank Automatic Valve

Suction Pressure 26 lbs

B) Beater Motor - Single Phase

H.O.M. cutout Amperage - 5 A

Overload cutout Amperage - 5.5 A

Voltage - 115 Volt

Beater rotation: counter clockwise -

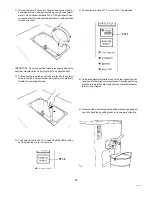

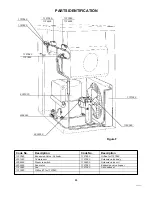

Electronic Hard-O-Matic Control Adjustment

If the H.O.M. needs to be recalibrated proceed as following:

Clamp on a calibrated Ampmeter on the BLACK wire (see page

35).

Start the machine with product in the hopper and cylinder.

The compressor must cut off when the current, absorbed by the

beater motor, reaches the amperage indicated in the technical

information above.

To reduce product consistency, turn the TRIMMER adjustment,

(see pag. 34) counter clockwise.

To increase product consistency, turn the TRIMMER adjustment

screw clockwise.

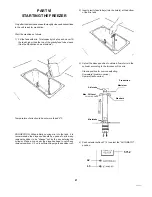

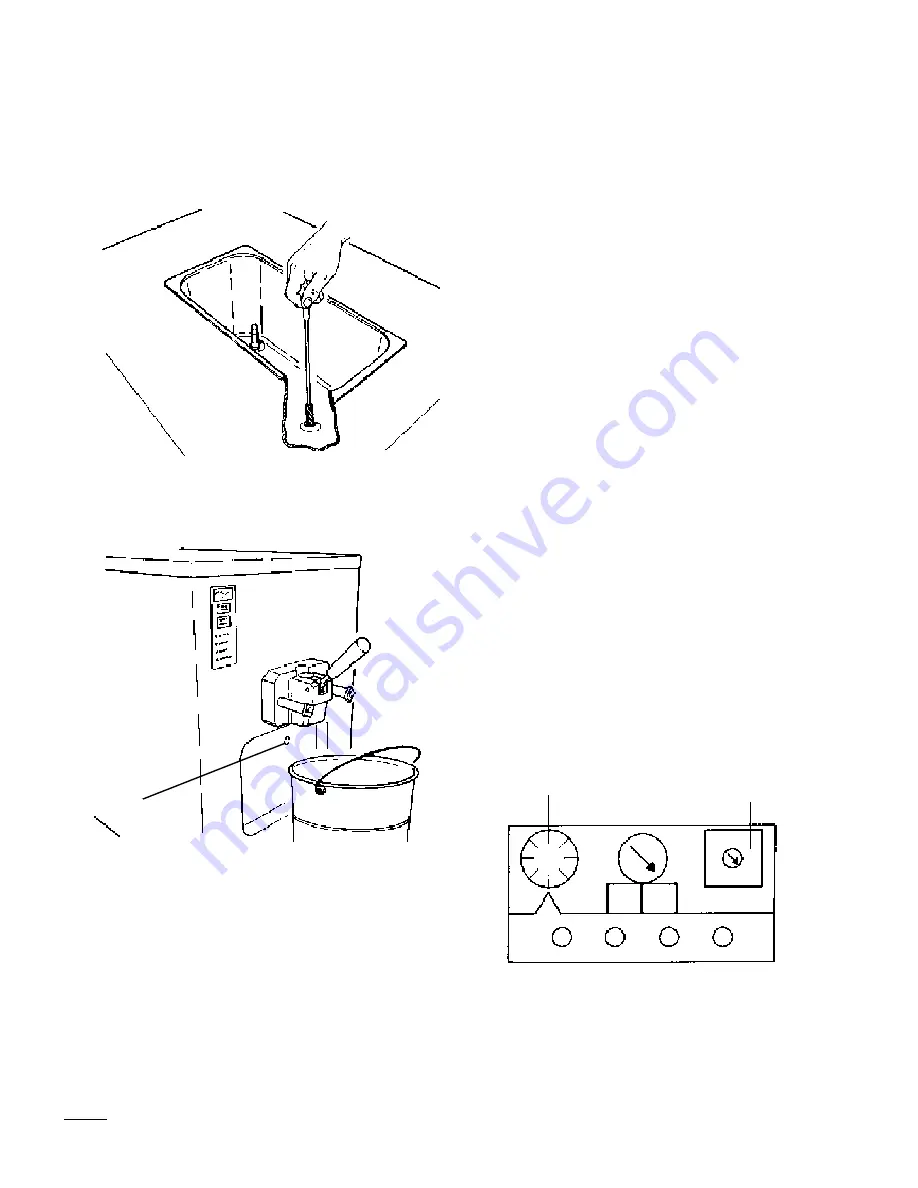

C) Overload

T 25 - 4.5/6.5

Calibrated - 5.5 A

The beater motor overload is controlled by the front switch pad.

The mode of the overload is in AUTOMATIC, if the overload trips

off, wait a few minutes and reset the overload pushing the “STOP/

RESET” button on the front switch pad.

AMP.

CALIBRATION

ALWAYS IN

R POSITION

MAN AUT