27

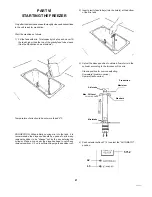

PART X

MAINTENANCE

Your COLDELITE machine has been designed, engineered and

manufactured to achieve high performance and long durability.

The life expectancy of a machine, any machine, does not depend

only on the quality of its components and design, but also on the

beneficial effects of basic maintenance procedures.

It is important to you, therefore, to become familiar with a few of

these basic procedures:

1) Remove O-rings only with the O-ring extractor supplied with

the machine.

2) Clean the machine according to the instructions.

3) Lubricate all O-rings and seals, as instructed.

4) The wearing or the improper cleaning of the beater shaft

seals, will result in leakage from the rear. Check the drip

chute pans frequently and replace seals, when so necessary.

5) Replace any O-ring that has a nick in it. If not replaced, it will

leak and interfere with the proper performance of the machine.

6) When all the spare parts supplied with the machine are used,

re-order immediately. Do not wait until the part is required

again.

7) NEVER use the AUTO position for washing, sanitizing and

initially filling the freezing cylinder.

8) IMPORTANT - During the washing and sanitizing period, run

the machine only for the time strictly necessary for this

operation. Prolonged use of the beater in the Cleaning

position may cause severe damage to the machine.

9) Always wash metal, plastic or rubber parts in lukewarm

water. NEVER, NEVER USE HOT WATER!

Important

If your Model is an air cooled machine, its efficiency depends on

the air cooled condenser. The fins of the condenser must be

cleaned every two or three months to assure efficiency.

Warning

Extreme care must be taken when removing side, rear or control

box panels.

Always turn the Selector Switch to the OFF position. Also, turn off

the Disconnect Switch on the electrical supply line before

exposing any electrical connections and/or moving parts, such

as belts, pulleys, fan blades and beater.

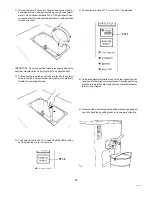

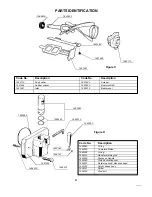

L1

570

A series of messages are available for interactive use of the

machine.

Message

When it appearsMeaning

- P_A

- Automatic /Stand-By

-Thermal sensor out

of order

- ICE

- Automatic

-Cylinder

temperature too low

- rtA

- At any time

- Overload relay

- 888

- At any time

- EPRON out of order

- MIP

- At any time

- Spigot head not

properly fixed;

thermal sensor out

of order

See page 28 for suggested remedy.

Power failure

In the event of a temporary power failure, when power supply

resets, the machine turns itself back to the same function before

power failure.

Power ON

When the machine is connected to the power supply, all leds and

displays illuminate on for 1 sec. to make a self test; just after, the

display shows for 2 seconds, 3 numbers corresponding to

thousands of cones extracted and then the display shows, for 2

seconds, other 3 numbers corresponding to the number of cones

extracted.

If you wish to Reset the number of cones, disconnect the machine

from the circuit breaker supply, push Stop and then turn ON the

Main circuit breaker while pushing Stop for the whole period of

display test.

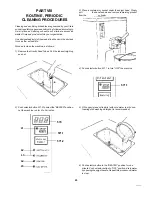

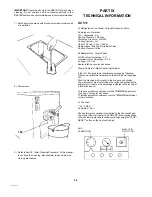

D) PROXIMITY SWITCH

The sensitivity can be adjusted with a small screwdriver. The

trimmer rotation is limited to 270 degrees by a “stop”. When

adjusting towards “maximum” or “minimum”, be careful not to

exert excessive torque (max. 40 Nmm) against the “stop”.

Failure to do so would damage the trimmer permanently.

Adjusting Proximity Switch

The proximity switch pos. 152 been preset at the factory and its

range is 9 inches approx.

If modification is required, contact authorized service agency as

this operation must be carried out by specialized technicians.

Messages visible on the Monitor