5

Important

Failure to closely follow operational and maintenance procedures

may result in damage to the unit and/or void your warranty.

Coldelite Corporation will not be responsible for any machine

not properly maintained.

In the event this unit should malfunction, please contact your

Coldelite Distributor or an authorized service agency.

PART I

INSTALLATION

Before starting this procedure, make sure the shipping case

does not show any evidence of having been dropped, tampered

with or abused in such a way as to indicate that its contents may

have been damaged in transit.

IMPORTANT: Should the outside of the shipping case give any

indication of possible hidden damage, state this on the bill of

lading before signing. Contact the carrier immediately and

request an inspection of damage. If this procedure is not adhere

to, you will forfeit your right to file damage claim and be responsible

for subsequent repair costs.

A)Uncrating

Proceed, as follows:

1) The case is secured to the skid with plastic strapping.

When you cut this strapping, do it with caution, as it may

spring out. Remove case by lifting it straight up and away

from the machine.

2) The freezer is also secured to the skid with plastic strapping.

Exercise caution and cut this strapping to free the machine

from the skid.

3) Remove the single screw at the bottom of each side panel.

Remove the panels by sliding upward slightly,

t h e n

pull

outward at the bottom and allow the panel to slide

down. The

protective plastic coating which

i

s

laminated to the panels

can now be removed by

simply peeling off.

B)Positioning the Machine

1) The freezer is shipped without legs installed. To install

the legs, lift the freezer and screw the four legs into the

bottom of the frame at each corner. When the freezer is

placed in the desired location, it must stand level. Level

the freezer by turning the bottom part of each leg in or

out. Check for level condition by placing level on the top

of the freezer at each corner.

NOTE: Accurate leveling is necessary for correct drainage of

freezer barrel and to insure correct over-run.

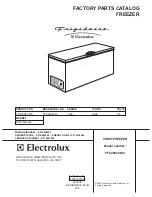

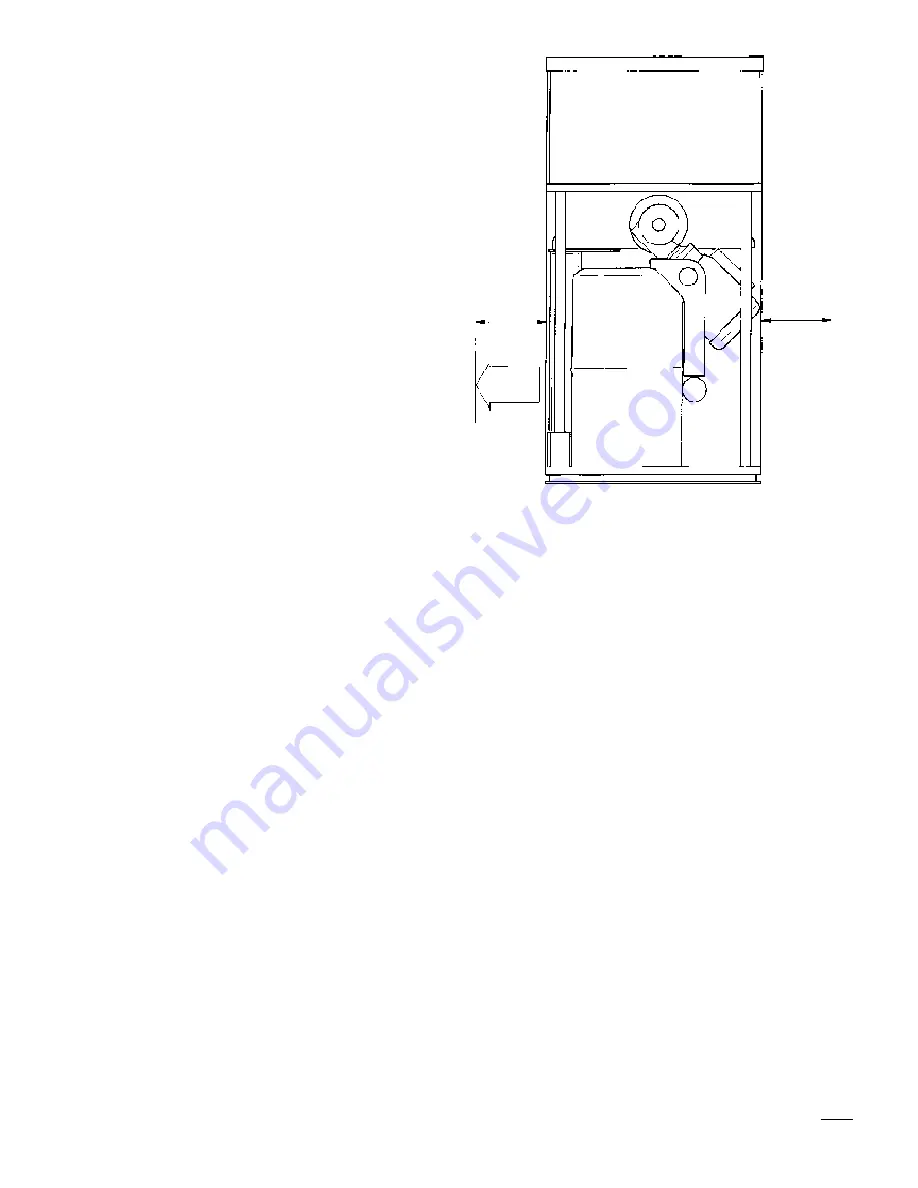

Figure 1

Clearances Required for

Air Cooled Models

2) The freezer is now ready to be positioned onto your

counter. The counter must be capable of supporting 180

lbs. and should be vibration free. Reinforce it, if necessary.

Remember when choosing a location, if your unit is air

cooled, proper air flow will need to be maintained. Allow

at least 8 inches on left side and a minimum of 6 inches

between the right side of the machine and any obstruction.

(Ref. Fig. 1).

Note: If these clearances are not maintained, the production

capacity will be reduced, cycling will increase and the potential

will exist that the machine will stop completely.

3) It is necessary to clean the condenser each month to

eliminate dust, paper, etc. which may obstruct it, damaging

the proper functioning of the machine.

4) The machine should also be within six feet of the power

supply (a plug and receptacle or unfused disconnected).

5) Position the machine for easy accessibility for cleaning,

servicing and maintenance.

6) Position the machine away from direct sunlight. For every

2°F over 68°F, the machine’s performance will decrease

by approximately 1%.

7) Once the machine is set in position, it should be leveled

as accurately as possible.

Air

Flow

8"

6"

Rear View