6

C) Electrical Requirements

All wiring installed to operate this freezer must be in accordance

with the National Electrical Code and/or local electrical codes,

rules and regulations. The machine must be properly grounded.

It is recommended the power supply be installed by a licensed

electrician.

Voltage UC 511: 115 Volts

Total Running Amperage FLA: 18 Amps.

Fuse Size: 20 Amp. Max.

Wire Size (50 Ft. Max.): # 10

Power Supply must be adequate to meet requirements at all

times. Voltage fluctuations, with the machine in operation, should

not exceed ± 5% of the normal or rated voltage.

Adequate Wiring must be provided with respect to wire size or

gauge. Unless otherwise required by the local Electrical Code,

the same size wire gauge at the machine junction box should be

used for direct power line. A separate circuit breaker with

adequate fuse protection should be employed.

An unfused disconnected switch or a properly sized plug and

receptacle within 6 feet of the freezer, is recommended.

Coldelite freezers are equipped with protection for the beater

motor. Should the line voltage drop, or in the unlikely event a

short circuit occurs, the overload protector will automatically

disconnect the starter and the machine will stop immediately so

that no permanent damage can be caused to the motor.

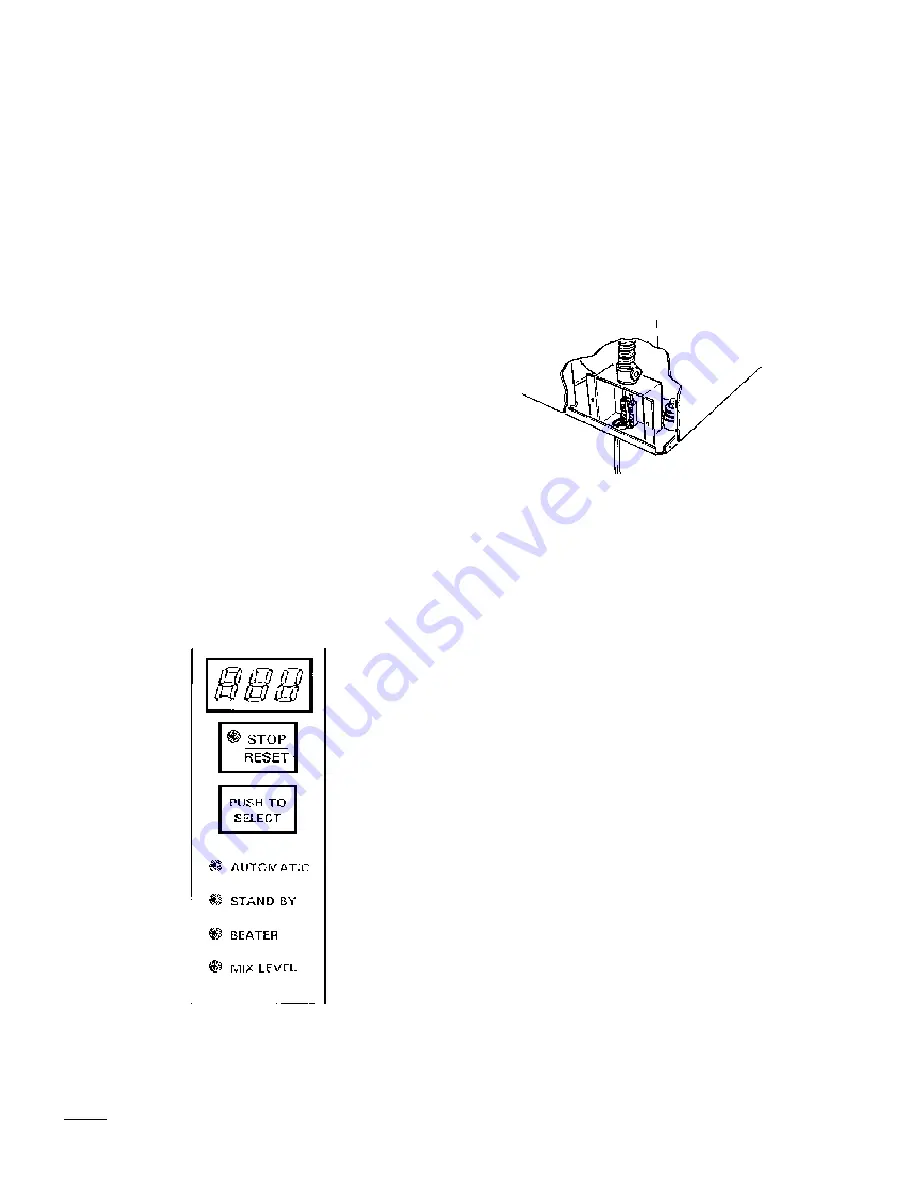

To restart the freezer, depress the STOP/RESET button located

on the front switch pad.

The heater protection must cool down for several minutes before

the RESET will operate. See Fig. 4.

The compressor is also internally protected. If the Klixon protector

trips due to an overload, again the protector must first cool down

for several minutes before the compressor can be restarted.

Electrical Connections

(Ref. Fig. 5)

Having removed the right side panel, the machine’s wiring

connection box can be found on the bottom of the frame and is

labelled “Connect Power Line Here”.

The power line is first passed through the access hole located

at the bottom deck directly below the wiring connection box. The

power line may then be connected to the machine’s power lines

and wiring connection box. Upon completion, the power line

should be fastened to the wiring connection box with appropriate

electrical hardware.

In all installations, the machine must be properly grounded.

Since all high voltage components (controls are 24 volts) are

connected by means of flexible conduit, or cord, adequate

ground continuity is assured by running and fastening a ground

line to the machine junction box ground lug. (Ref. Fig. 5).

Beater Rotation

After electrical connections are completed, check the rotation of

the beater. It should be counter clockwise when facing the front

of the machine.

D) Completing the Installation

On the following pages, you will find important information and

procedures which describe the proper installation, sanitizing,

operation and maintenance of your COLDELITE machine. We

feel certain that your full compliance with these instructions will

assure you of excellent performance, trouble-free operation and

a profitable business for years to come.

NOTICE: Failure to closely follow set-up and maintenance

procedures can void your warranty. Coldelite Corporation will

not be responsible for any machine not properly maintained.

In the event this unit should malfunction, please contact your

Coldelite Distributor or an authorized service agency.

WARNING:EXTREME CARE MUST BE TAKEN WHEN

REMOVING SIDE, REAR OR CONTROL BOX PANELS.

ALWAYS TURN THE MACHINE TO THE OFF POSITION. ALSO

TURN OFF THE DISCONNECT SWITCH ON ELECTRICAL

SUPPLY LINE BEFORE EXPOSING ANY ELECTRICAL

CONNECTIONS AND/OR MOVING PARTS, SUCH AS BELTS,

PULLEYS, FAN BLADES AND BEATER.

Figure 5

Figure 4