7

Stand-by function

This position is used during prolonged idle periods. The

temperature of the product in both the mix tank(s) and freezer

cylinder (s) is held at a safe temperature and controlled

automatically by the thermostats. Product should never be

served when in this position as the “storage” temperature is

higher than normal serving temperatures.

In this position the beater motor is ON when the system is

cooling the cylinder, beater motor is OFF when the system is

cooling the hopper which will allow significant ENERGY

CONSERVATION.

Beater function

With this function on, pilot light pos. L4 on, only the beater

turns while the refrigeration system is cut out. This function

is timed and ends automatically when the set time is over.

About 15 minutes.

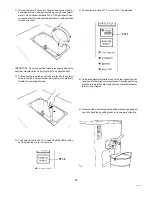

Hopper Mix level indicator

This pilot light pos. L5 indicates that the level of the mix

in the hopper has reached the minimum allowed, and that

more mix must be added.

When illuminated, dispensing of product should be stopped and

the tank refilled with mix. Each tank has a total capacity of 6 qts

each when full.

The MIX LEVEL SWITCH is located within the stainless steel/

plastic rod attached to the bottom of each mix tank.

L1

L2

L3

L5

L4

570

571.1

571.2

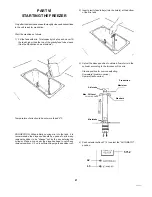

PART II

EXPLANATION OF CONTROLS

A) Electronic Control Panel

Positions L1/L5 Lighted function indicators

These indicators illuminate to show that the function

corresponding to the signal next to the indicator itself is

on.

Monitor pos. 570

This numerical monitor displays the consistency of the product

when the machine is turned on and while it is operating in

AUTOMATIC.

Stop/Reset button pos. 571.1

With the Stop/Reset function on, pilot light pos. L1 lit, the

machine is ready to receive the command for any of the

main functions.

Select button pos. 571.2

By pushing this button you can select the functions:

-Automatic

-Stand-by

-Beater

Indicators illuminate to shown that the function corresponding

to the signal next to the indicator itself is on.

Automatic function

When this function is on, pilot light pos. L2 lit, the product

is processed until it reaches the proper consistency (pre-

set HOT setting). During this function, The Monitor displays

a number indicating the consistency of the product in the

cylinder until it reaches the set value, then it indicates the

temperature of the mix in the hopper tank.