24

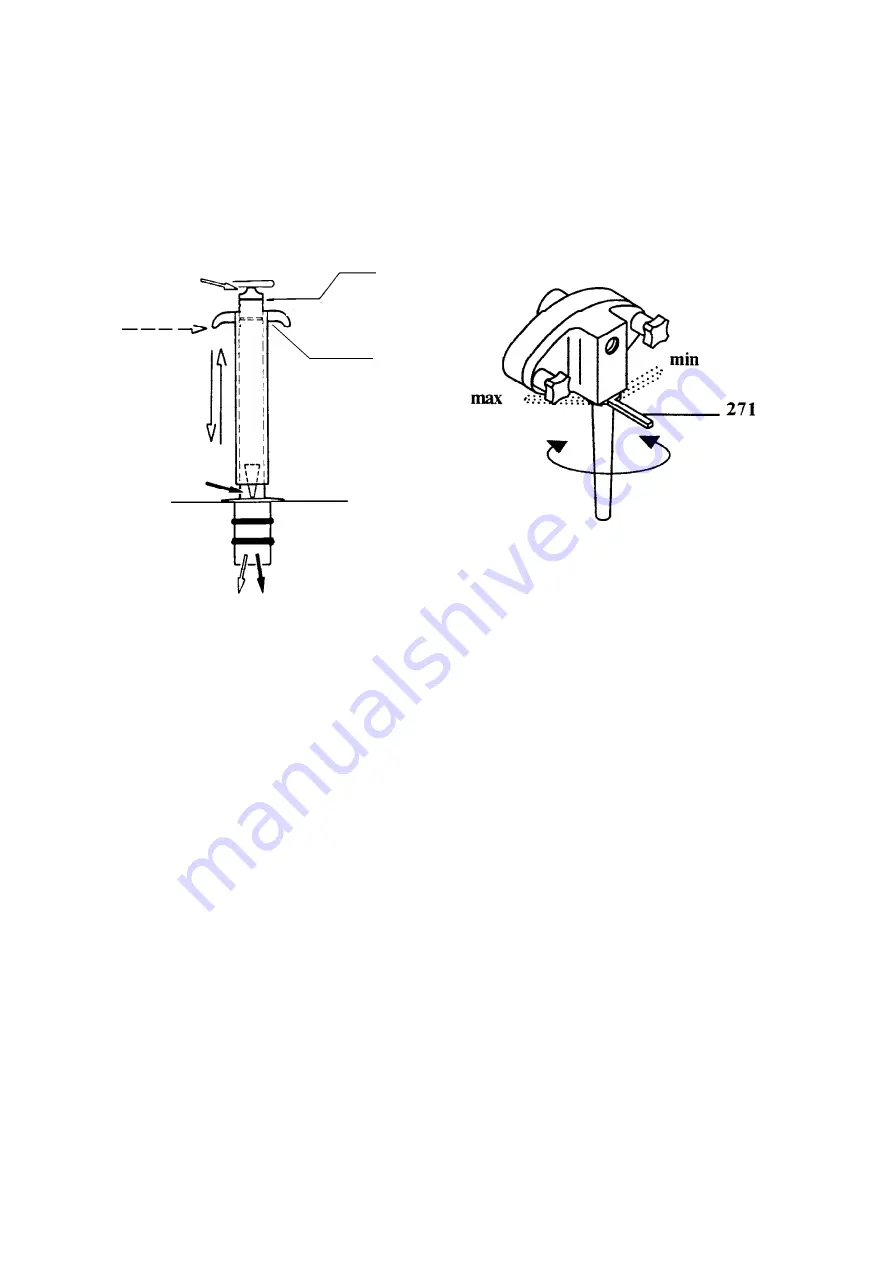

B) Gravity Fed Machines

The gravity feed tube consists of two tubes, one

sliding inside of the other, and a center splash

guard. The inner tube blends the flow of air and

mix into the freezing cylinder. Air enters through

the top of the tube, mix through the bottom.

(Refer to figure 9)

Figure 9

The outer tube is actually a regulating valve. Lif-

ting or closing this outer tube changes the hole

opening size on the inner tube which allows more or

less mix to enter the freezing cylinder. Since the air

inlet hole size does not change, the air inlet is

constant.

You can vary the overrun (yield) by allowing more

or less mix to enter the cylinder by changing. You

do this by opening or closing the outer regulator

sleeve setting on the inner feed tube.

The inner splash guard keeps mix from splashing

the underside of the mix tank cover as well as elimi-

nate clogging of the feed tube.

The draw rate, portion size, and mix viscosity will

determine the final regulating sleeve setting. Our

standard setting is 2 to 3 notches up from the

bottom. Open the outer tube to increase the mix

amount. Close the outer tube to decrease the mix

amount. Adjust for your specific application.

C) Pump Fed Machines-Operation

The mix injection pump runs whenever the beater

drive motor is turning. To regulate the amount of

mix being injected into the cylinder, pivot the pump

suction tube either to the right (less mix/more air)

or to the left (more mix/ less air). (Refer to figure

10)

Figure 10

The air intake is through the front two holes of the

pump cover. Since the two air inlet holes are fixed,

the air intake is constant. To adjust your overrun

(yield) you must regulate the amount of mix being

pumped into the cylinders. The mix pump suction

tube will change the orifice size on the tube to

allow either more or less mix to be pumped into the

cylinder.

You will also have to adjust your pump suction

tube during daily operation to either a larger (Left)

or smaller (Right) orifice setting depending on your

draw rate and product viscosity.

For heavy draw rates and / or thick viscosity

mixes, a setting of center, one, two, or three

positions to the left of center will be necessary in

order to operate the machine properly.

For light draw rates and / or thin viscosity mixes, a

setting of center, one, or two positions to the right

of center will be necessary.

The “Normal” operating position for the suction

tubes on this freezer is either one position to the

left, center, or one position to the right.

Mix Intake

Max. Fill Level

Air Intake

Maximum

Standard