5

4) It is necessary to clean the air condenser each

month to remove dust, paper, etc., which may

obstruct airflow. Prior to cleaning the condenser

from the inside, disconnect the machines power

supply.

5) The machine should be connected to a fused

disconnect no more than six feet away. Electrical

installation

MUST

comply with state and / local

electrical codes.

6) Never position the machine in direct sunlight or

near a heat source. This will reduce its performance

and possible damage the freezer.

7) Water connections (Water Cooled Only)are made

at the rear of the machine. A minimum of ½ inch

(ID) water supply and drain lines are recommended.

Both the water inlet and outlet lines must remain

unobstructed or the machine performance will be

affected.

C) Electrical Requirements

All wiring installed to operate the freezer must be in

accordance with the National Electric Code and / or

local electrical codes and regulations.

!! IMPORTANT !!

This machine must be properly grounded.

Failure to properly ground the freezer may result

in dangerous and / or fatal electric shock.

The main machine power supply must meet

requirements at all times of operation. Voltage

fluctuations

must not

exceed plus or minus 5% of

the rated nameplate voltage.

All Coldelite machines are equipped with step down

transformers for the control circuit supply. These

transformers have a “multi-tap” input which must

be wired to match the inlet voltage

(ie. 208 or 230 vac). Failure to wire to the correct

supply voltage can result in machine malfunction.

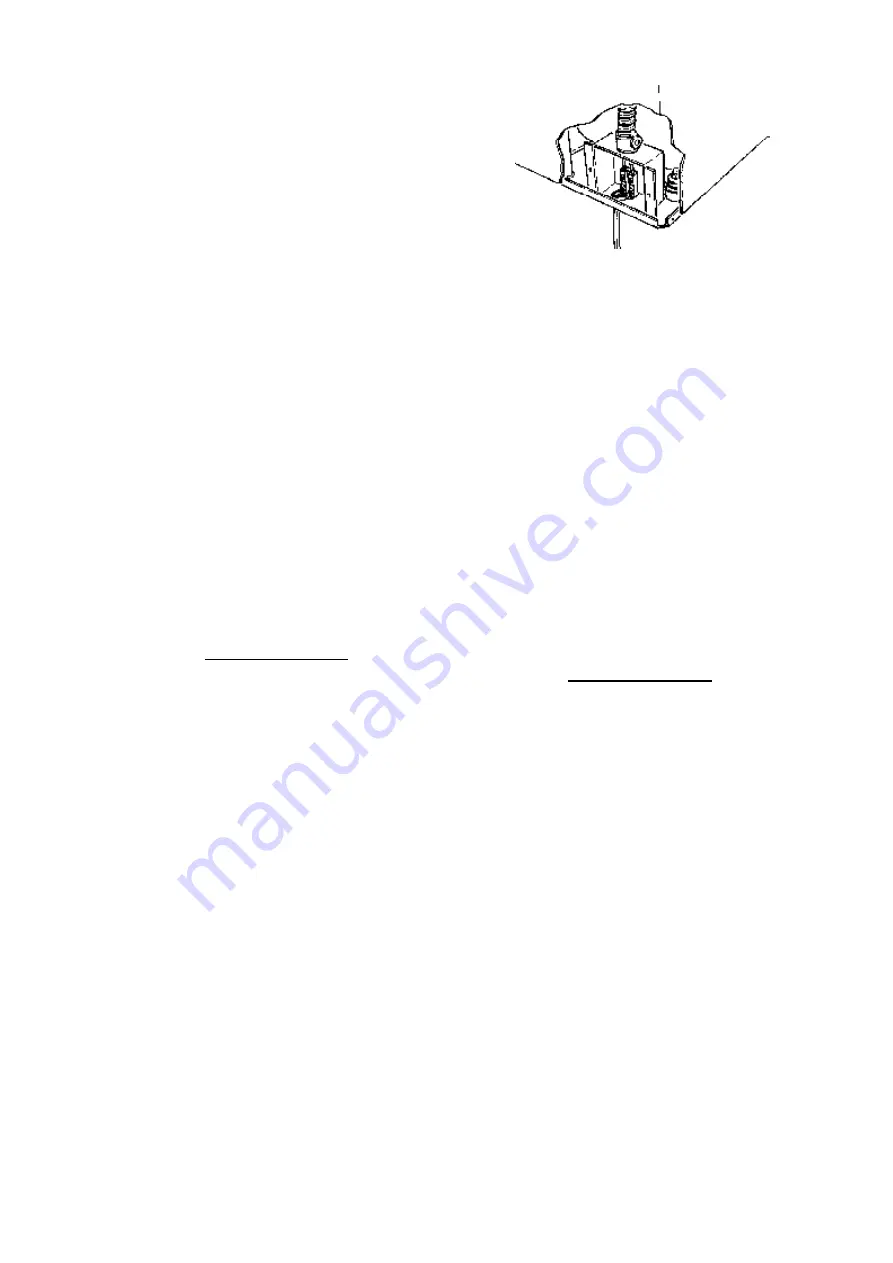

Electrical Connection –

( Refer to Fig. 3 )

Having removed the side panels from the frame, the

main power connection box is located on the bottom

of the frame. The connection box is labeled

“Connect Power Line Here”. Connect the power

supply wires to the machines using the appropriate

electrical hardware and strain relief devices.

Figure 3

After the electrical connections are completed,

turn the power supply on. At this time you must

check the beater / auger motor rotation. The

correct beater rotation ( Facing the front of the

machine ) should be clockwise.

D) Completing the Installation

1) All of the setup and calibration of this freezer

should be performed by an approved Coldelite

Service Technician. Failure to calibrate this freezer

properly can result in freezer damage and a voided

warranty.

2) After installation and calibration of both

electrical and refrigeration circuits, the side panels

should be reinstalled.

!! IMPORTANT !!

Failure to closely follow factory setup and

maintenance procedures will result in a voided

warranty. Coldelite Corporation will not be

responsible for any freezer which is not setup or

maintained in accordance with factory procedures.

NOTE: Always turn the machine OFF and

disconnect the power supply switch to the freezer

prior to exposing any electrical connections or

moving parts.

On the following pages you will find important

information and procedures which describe the

proper sanitizing, operation, and maintenance of

your Coldelite Freezer. We are certain that your

full compliance with instructions and procedures

will result in many years of trouble free operation.

In the event this unit should malfunction or need

maintenance, please contact your local Coldelite

Distributor or Authorized Service Agent.