2

5.1.1 The Controller is connected to the battery d irectly, wrong connect the poles doesn t destroy

the compressor and controller, but the compressor d o not work;

5.1.2 The fuse must be connected in the + cable to protect controller, which close to the power

supply, 15A fuse for 12VDC and 7.5A fuse for the 24 VDC are recommended;

5.1.3 If a main switch is used, it should be rated to current of min. 20A;

5.1.4 To prevent voltage dropping, please avoid ex tra junction in the power supply system.

5.1.5 A Light Emitting Diode(LED) for compressor o peration monitoring can be connected

between the ter and D .

Operational errors will cause the LED to flash a nu mber of times. The number of flashes

depends on what kind of operational error was recor ded. Each flash will last 1/4 second and

each error will repeat every 4 seconds. Operational errors show by Table 5, please see it in

page 6.

5.1.6 If a cooling fan is used. It must be connect ed

to electronic unit ter and F, only use

12VDC fan , no matter what power supply you are usi ng;

5.1.7 A Thermostat is connected between the termin al C and T of the electronic unit. It will start

or stop the running of compressor automatically;

5.1.8 A Resistor can be connected between terminal C and T, it allows you to adjust the speed of

the compressor, the relationship between the resist or and the compressor speed shown by

Table 3; please see it in page 3.

5.1.9 To ensure sufficient battery power for co mpr essor and avoid permanent damage to the

battery because heavy discharge. A battery protecti on resistor is connected between

terminal C and P, the different resistor will get t he different voltage protection, the details is

showed by Diagram 4;

PROCOLD S.r.l. - ITALY- 13043 CIGLIANO (VC)

C/so Umberto,58 - Tel (+39) 0161 42 44 52 Fax (+39) 0161 4 2 40 92

www.procold.it info@proco ld.it

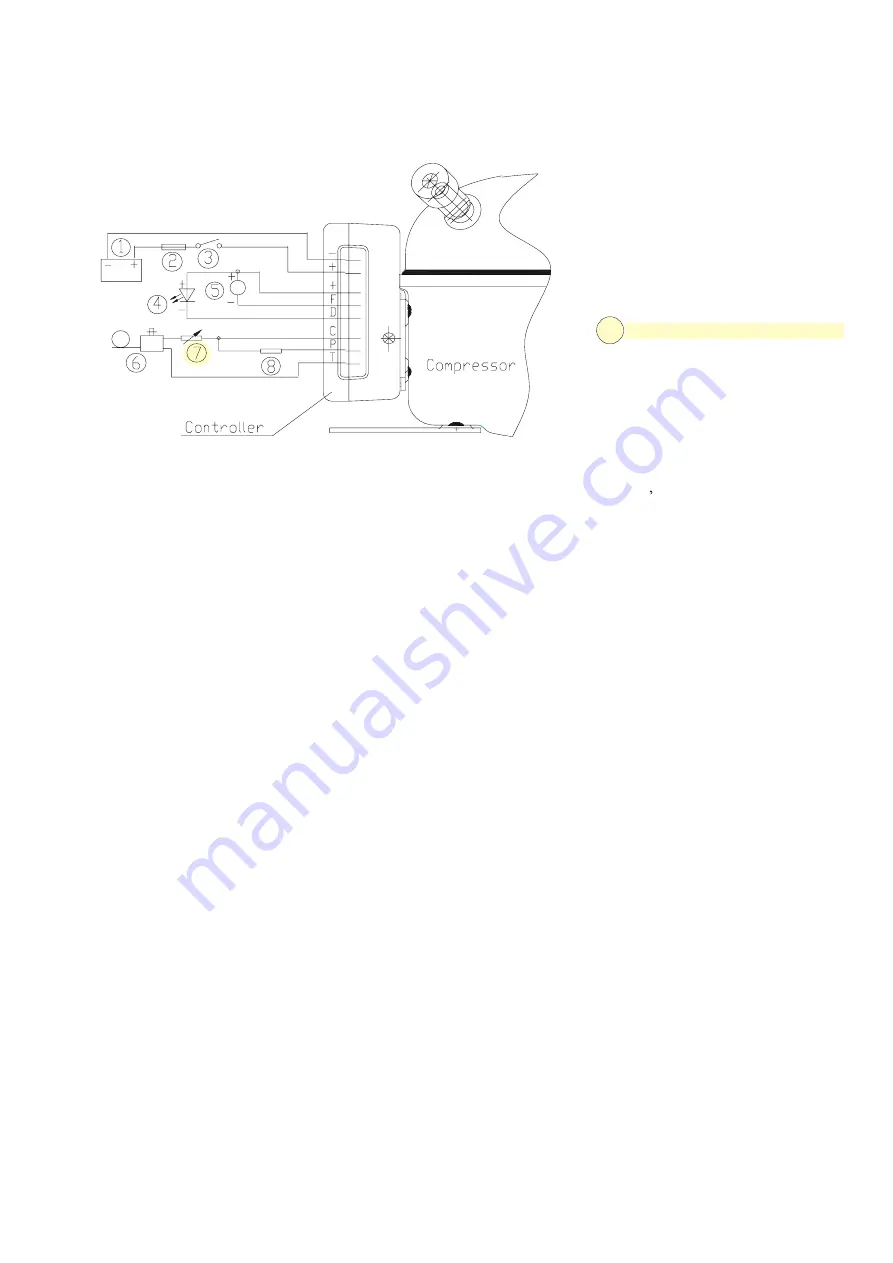

5 Controller

5.1

Wiring

The Compressors are equipped

with a brushless direct current

motor which is controlled by an Attached Controller, the wiring is shown as following drawing:

TD35 VS

and

TD50 VS

1 Battery

2 Fuse

3 Main Switch (optional)

4 LED (optional)

5 12V DC Cooling Fan (optional)

6 Thermostat

7 Resistor for presetting speed (optional) C-T

8 Resistor for presetting battery protection

voltage (optional) C-P

Rev. 2.0 27/02/2019