Controller calibrator to the applied voltage automa tically, when the battery voltage is lower

than 17 VDC, The controller consider it is working in a 12 V DC system, and When the voltage is

higher than 17 VDC The controll er consider it is wo rking in a 24 V DC system.

resistor is connected between C - P , the operating voltage range could be

9.6V

31.5V, this means

TD35 VS

and

TD50 VS

are very suitable for

application.

5.5

Error Indication

If the start failed, the controller will attempt r estarting every 60s, until a successful start is

achieved. The following Table shows the Error Type and reason.

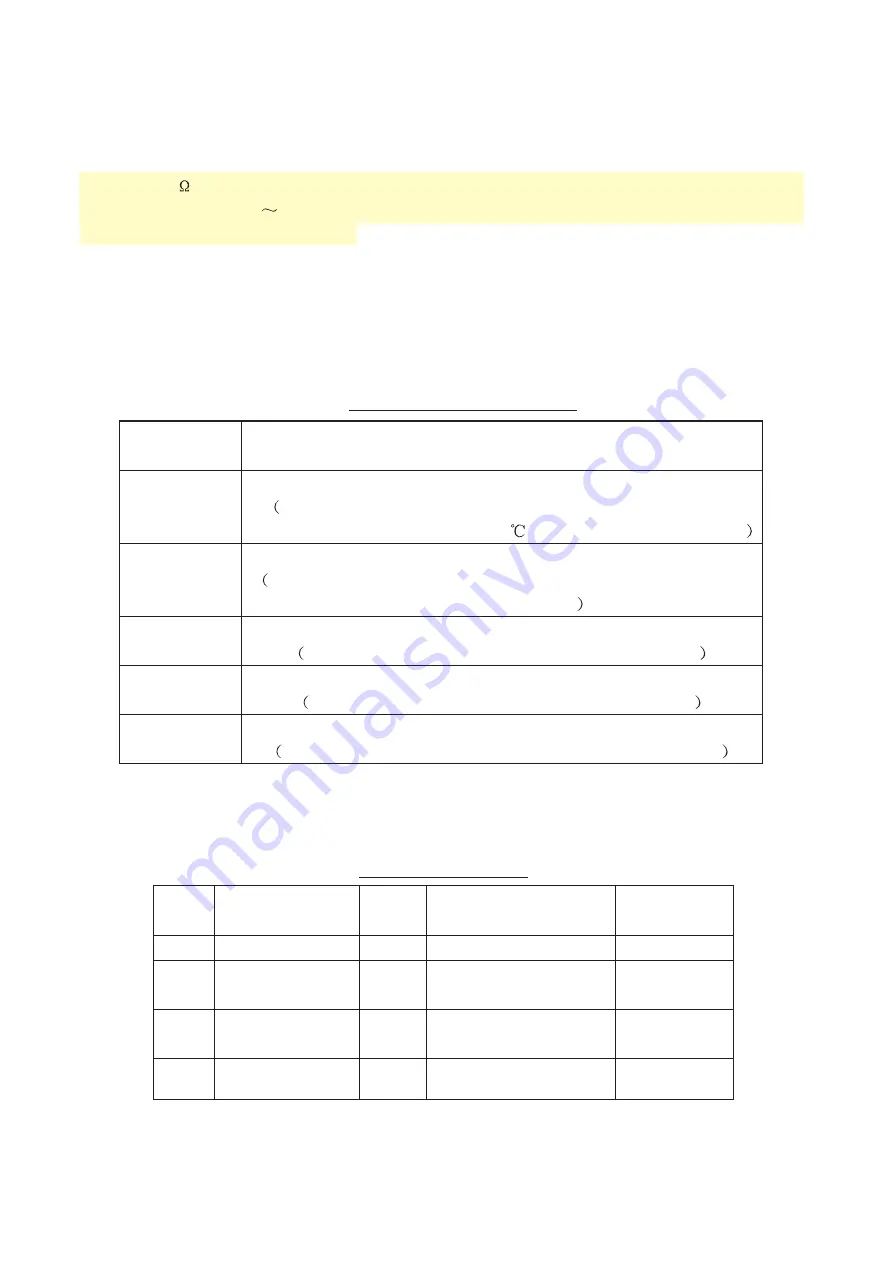

Table 5 LED Error Indications

Number of

flashes

Error Type

5

Thermal cut-out of controller

If the refrigeration system has been too heavily loaded, or if the

ambient temperature is high than 55

,the controller will run too hot

4

Minimum motor speed error

if the refrigeration system is too heavily loaded ,the motor speed is

lower than 1850 rpm

3

Motor start error

The rotor is blocked or the system pressure is too high

2

Fan over-current cut-out

The operating current of cooling fan is more than 1A

1

Battery protection cut-out

Battery Voltage is outside the setting range shown in Table 4

6

Accessories

Table 6 Accessories

No.

Title

Pieces

Model

Comments

1

Controller

1

12 - 24 Volt AUTO

2

1

Screw of

controller

(M4 x 8)

3

Rubber

grommet

4

RU HC 35-50-80

4

Grommet sleeve

4

SL HC 35-50-80

If a 220K

extended between

photovoltaic solar power

PROCOLD S.r.l. - ITALY- 13043 CIGLIANO (VC)

C/so Umberto,58 - Tel (+39) 0161 42 44 52 Fax (+39) 0161 4 2 40 92

www.procold.it info@proco ld.it

4

Rev. 2.0 27/02/2019