5

7.3 More than two layer package of compressors is no t available, and avoid any rolling during

loading and unloading.

7.4 After consignment, it is better store the compres sors not more than 6 months.

8 Precautions

8.1 The compressor is only allowed to be connect ed to a 12/24VDC system, it is forbidden to

connect compressor directly with an AC power supply.

8.2 The back gas tube on refriger ation system must be connected with the suction tube on

compressor, not the process tube on compressor; otherwise the compressor can t work in gear.

8.3 Please mount the compressor into the refrigerat ion system quickly in 10 minutes after uninstall

the tubes of the compressor (suggest to uninstall the process tube first).

8.4 The maximum ambient temperature of the compress or operation is 55

.When continuously

operating under the maximum ambient temperature 55

, the max condensing pressure and the

peak pressure should not exceed 1.75MPa and 2.17MPa.

8.5 Balance pressure 55

start the compressor the pressure in the compressor could not more

than 0.49MPa.

8.6 Do not operate the compressor before polyester is charged.

8.7 The refrigerant charge should be less than 200g

8.8 The interval of compressor operation

Operation is more than 3 minutes, and the stoppage is

more than 3 minutes too.

8.9 Special attention

Do not use the compressor as a vacu um pump, and do not start it under

vacuum status too.

8.10 The refrigeration system should minimize the c ontent of chlorines and moisture, and must be

free of paraffin and silicon.

8.11 In order to make the compressor work prope rly, the following cable dimensions must be

observed.

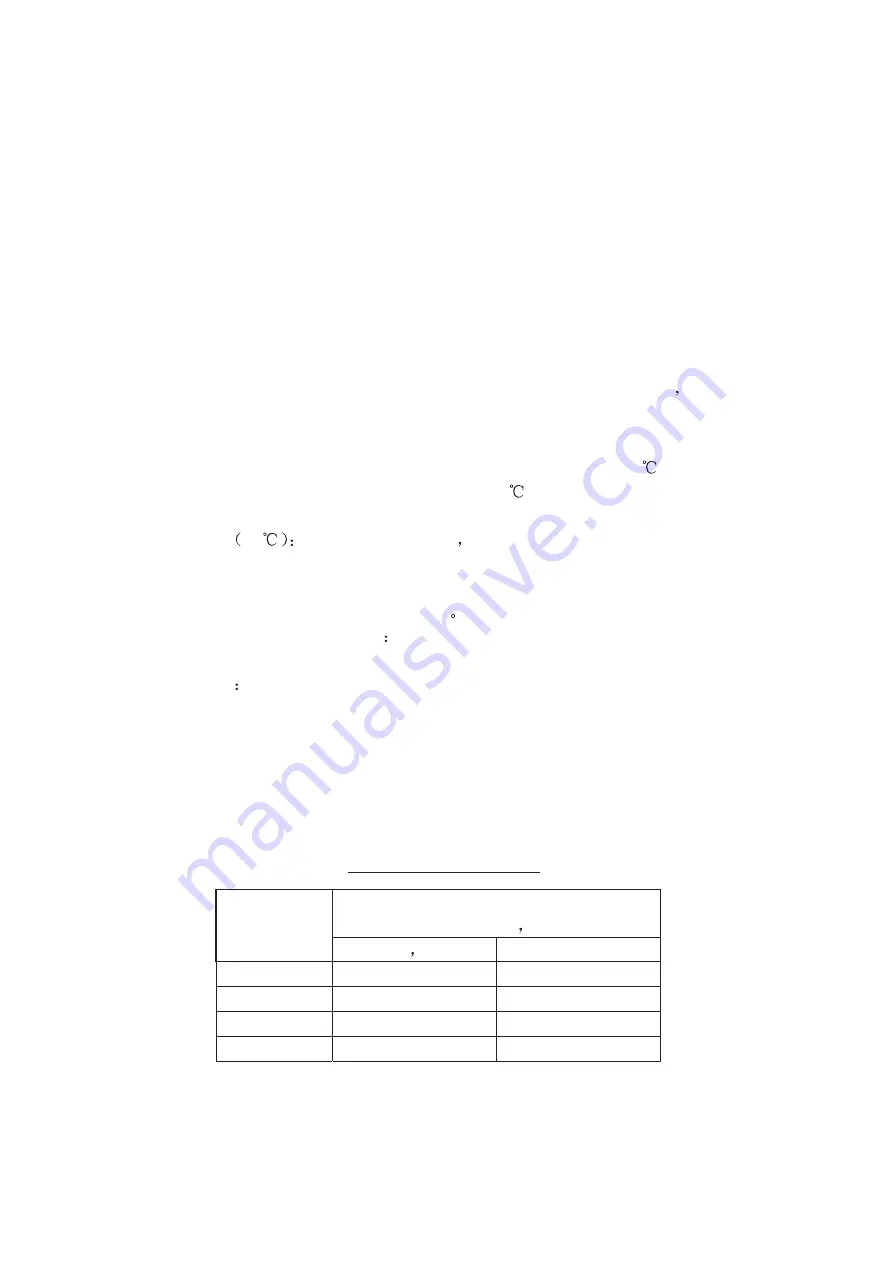

Table 7 Cable requirements

Max. Length between battery and

Controller

m

Cross-section

mm

2

12V

DC

24V,

DC

2.5

2.5

5

4

4

8

6

6

12

10

10

20

PROCOLD S.r.l. - ITALY- 13043 CIGLIANO (VC)

C/so Umberto,58 - Tel (+39) 0161 42 44 52 Fax (+39) 0161 4 2 40 92

www.procold.it info@proco ld.it

7 Transportation and storage

7.1 Please keep perpendicularity, can not be turn ed upside down and avoid vibration and shocks

during transportation.

7.2 Please ensure to store the compressors under dr y and well-ventilated condition to avoid the

package getting wet.

Rev. 2.0 27/02/2019