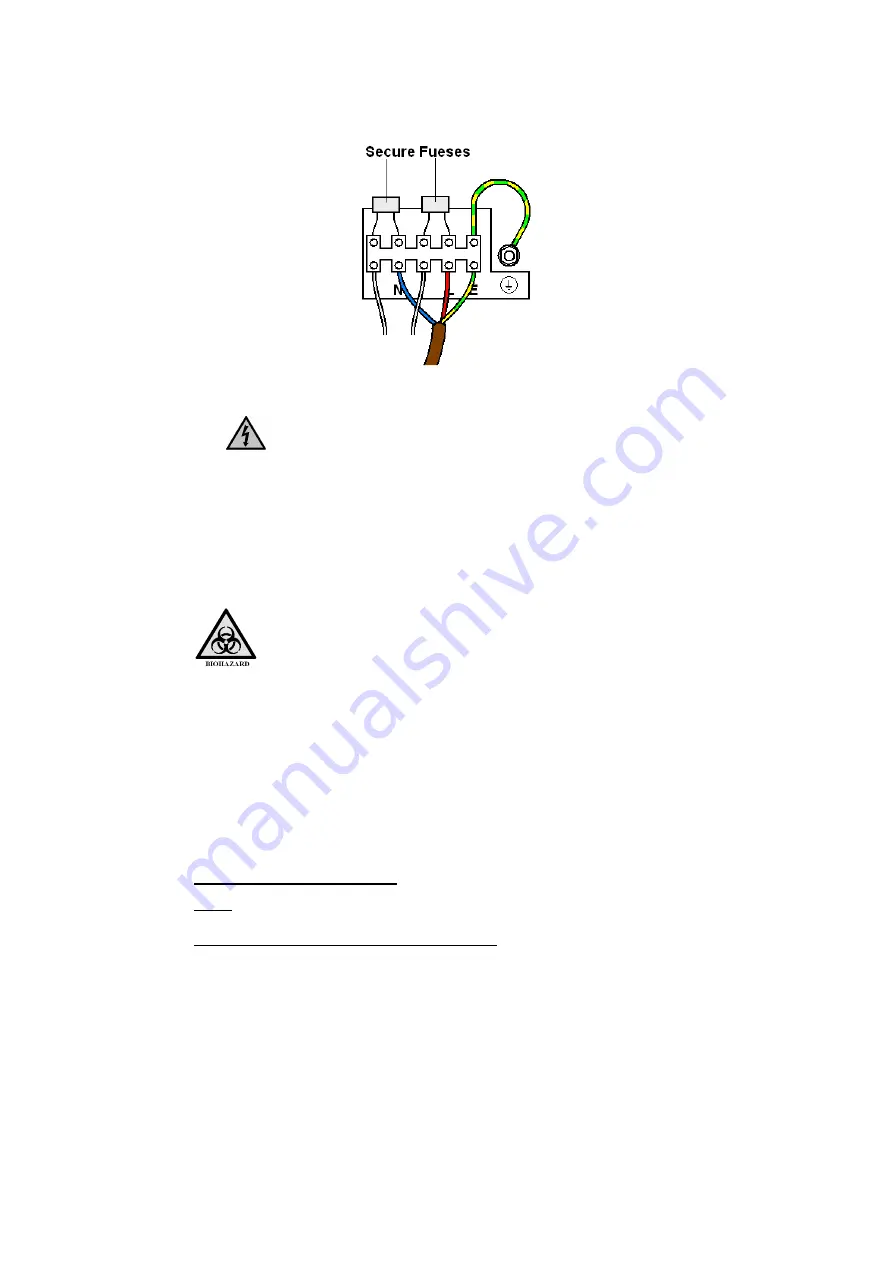

9.2.3. Unscrew the terminal block positions and remove the fuses. Fit replacement

fuses of the correct rate and value.

9.2.4. Reinsert the base into the body and secure using the previously removed

screws.

9.2.5.

Prior to further use, the Responsible Body shall check the electrical

safety of the unit.

9.3.

Decontamination.

In the event of spillage switch off and unplug this product from the mains electrical

supply. Wipe off all excess liquid from the reaction block and surrounding area using

an absorbent soft cloth. Allow sufficient time for any ingressed liquid to evaporate

before commencing with use.

If in doubt

,

please consult Customer Support. Refer to section 10.

If the equipment has been exposed to contamination, the

Responsible Body is responsible for carrying out appropriate

decontamination. If hazardous material has been spilt on or inside the

equipment, decontamination should only be undertaken under the control of

the Responsible Body with due recognition of possible hazards. Before using

any cleaning or decontamination method, the Responsible Body should check

with the manufacturer the proposed method will not damage the equipment.

Prior to further use, the Responsible Body shall check the electrical safety of

the unit. Only if all safety requirements are met can the unit be used again. The

above procedure is intended as a guide. Should spillage occur with a toxic or

hazardous fluid then special precautions may be necessary.

Decontamination Certificate.

Note:

In the event of this equipment or any part of the unit becoming damaged, or

requiring service, the item(s) should be returned to the manufacturer for repair

accompanied by a decontamination certificate.

Copies of the Certificate are

available from Distributor/Manufacturer.

At the end of life, this product must be accompanied by a Decontamination

Certificate. See section 6.3 and 6.4

16