9

Leak Check

WARNING

• Perform all leak tests outdoors.

• Extinguish all open flames.

• NEVER leak test when smoking.

• Do not use the heater until all connections have been leak tested and

do not leak.

■

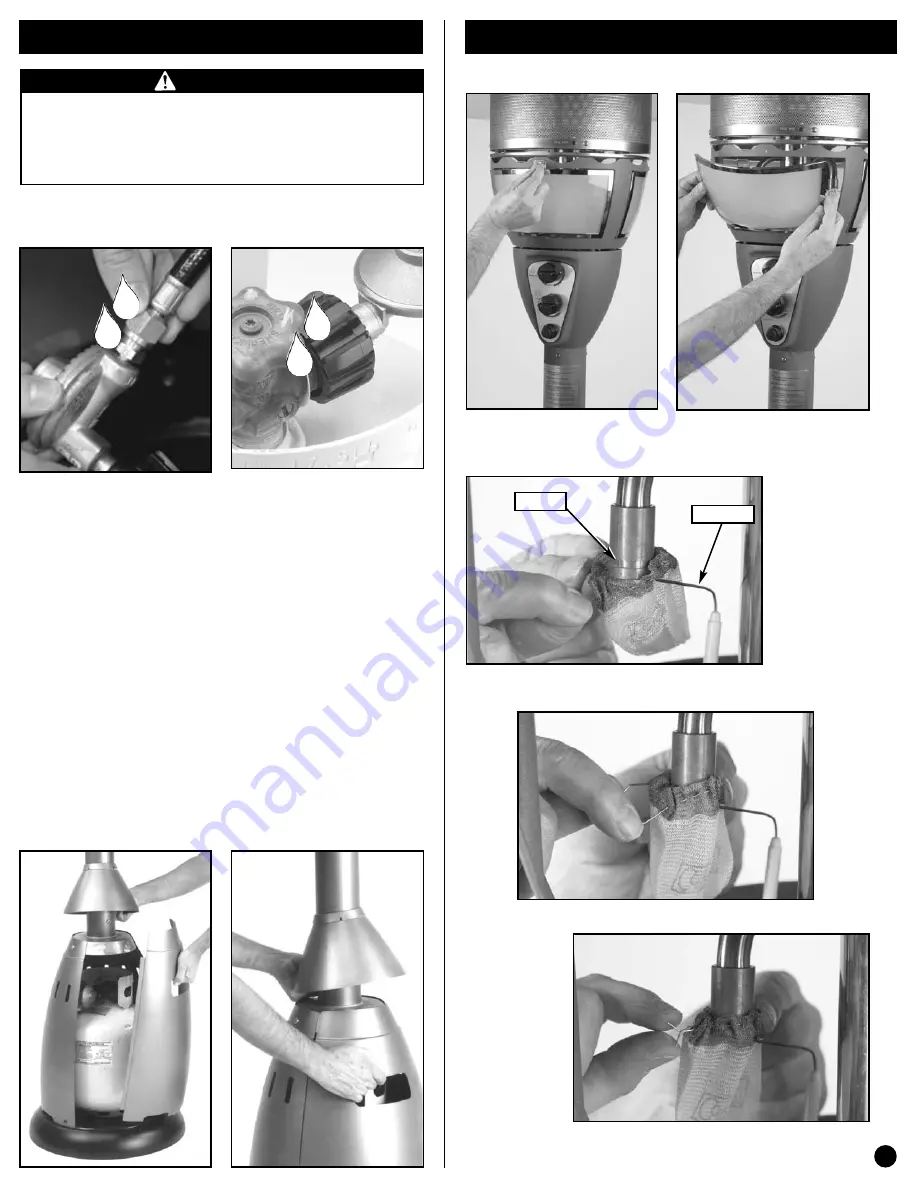

Lift cover while installing

remaining cylinder cover section.

Hose/Regulator

Connection

Regulator/Cylinder

Connection

■

Complete installation.

• Make 2-3 oz. of leak check solution (one part liquid dishwashing

detergent and three parts water).

• Apply several drops of solution where hose attaches to regulator.

• Apply several drops of solution where regulator connects to Cylinder.

• Make sure all Patio Heater & Light valves are OFF.

• Turn Cylinder Valve ON.

If bubbles appear at any connection, there is a leak.

• Turn Cylinder Valve OFF.

• If leak is at Hose/Regulator connection: tighten connection and perform

another leak test. If you continue to see bubbles after several attempts,

contact 1-800-835-3278 for assistance.

• If leak is at Regulator/Cylinder Valve connection: disconnect, reconnect,

and perform another leak check. If you continue to see bubbles after sev-

eral attempts, cylinder valve is defective and should be returned to cylin-

der’s place of purchase.

If NO bubbles appear at any connection, the connections are secure.

• Turn Cylinder Valve OFF.

NOTE: Whenever gas connections are loosened or removed, you

must perform a complete leak test.

Mantles

■

Remove 2 glass panels.

■

Slip mantle onto burners. Align clips in mantle with groove in burner. Be

sure clip points away from electrode.

■

Twist clips.

Electrode

Groove