ASSEMBLY

1. Unpack the air compressor and inspect the unit for

damage and parts. If the unit has been damaged or

some parts are missing, contact the Service Center

immediately.

2. Check the serial tag label to ensure that it has the

required pressure rating for its intended use.

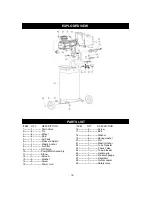

3. Unpack the smaller plastic bag with the air filter

included and have the air filter (A) assembled on

the pump. (See Figure 2)

4. Locate the compressor according to the following

guidelines:

a. Set the compressor in a position near a

grounded electrical outlet.

b. The compressor must be at least 12 inches

away from any wall or obstruction and in a

clean, well-ventilated area to ensure sufficient

air flow and cooling.

c. The compressor must be level to ensure

proper drainage of the moisture in the tank.

d. In cold weather, store the compressor in a

heated building when not in use. This will

reduce problems with the motor starting and

freezing from water condensation.

5. Connect an air hose with a female connector fitting

kit to the compressor air line outlet.

A

- 6-