7

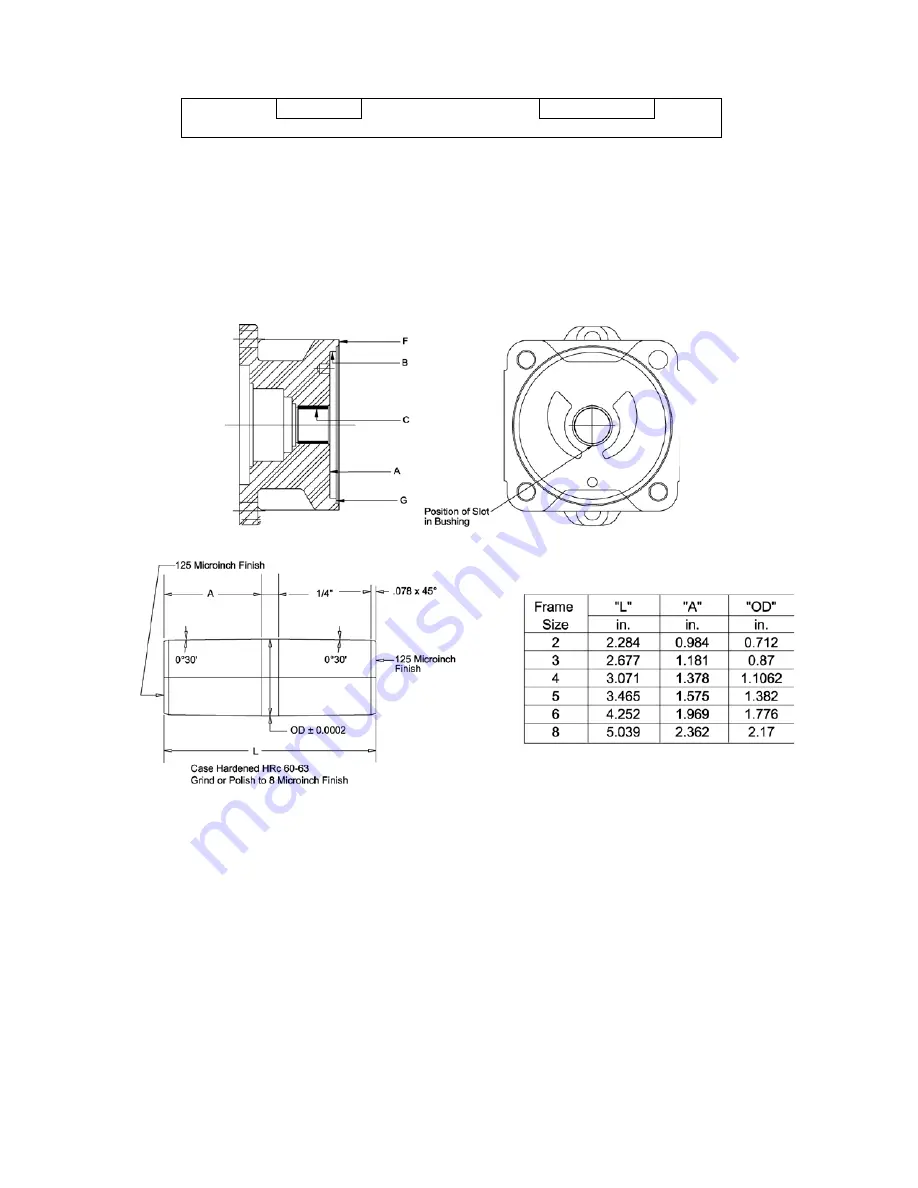

3. Machine face (A) deep enough to remove any scored material. Ensure that face is flat within .0008 inch TIR

with a 32 micro inch finish.

CAUTION

ATTENTION

Being out of flat in excess of .0008” can cause pump failure.

NOTE:

If more than .015” is machined (removed) from face (A, Figure 2), the same amount should be machined

(removed) from G and F, Figure 2.

4. Press sleeve bushing (53), (54) in from front cover or intermediate cover ensuring that split in bushing (53),

(54)is positioned as shown in Figure 2.

5. Fabricate a bushing sizing tool as shown in Figure 3. Press sizing tool through bushing from same direction

bushing was originally installed to properly size bushing bore.

Figure 2 – Front Cover

Figure 3 – Sleeve Bearing (53) Sizing Tool