Shaker

AGIA 200, VIBA 300 & VIBA 330

Collomix GmbH

D-85080 Gaimersheim

14

Version G 1.4-16

7.

Errors and Troubleshooting

The troubleshooting tables in this Chapter will help you to determine whether you can troubleshoot yourself or whether you need to call

customer service.

IMPORTANT

Jot down the serial number of the machine and the error code from the display before you call customer service. The machine's serial

number is on the type plate.

7.1

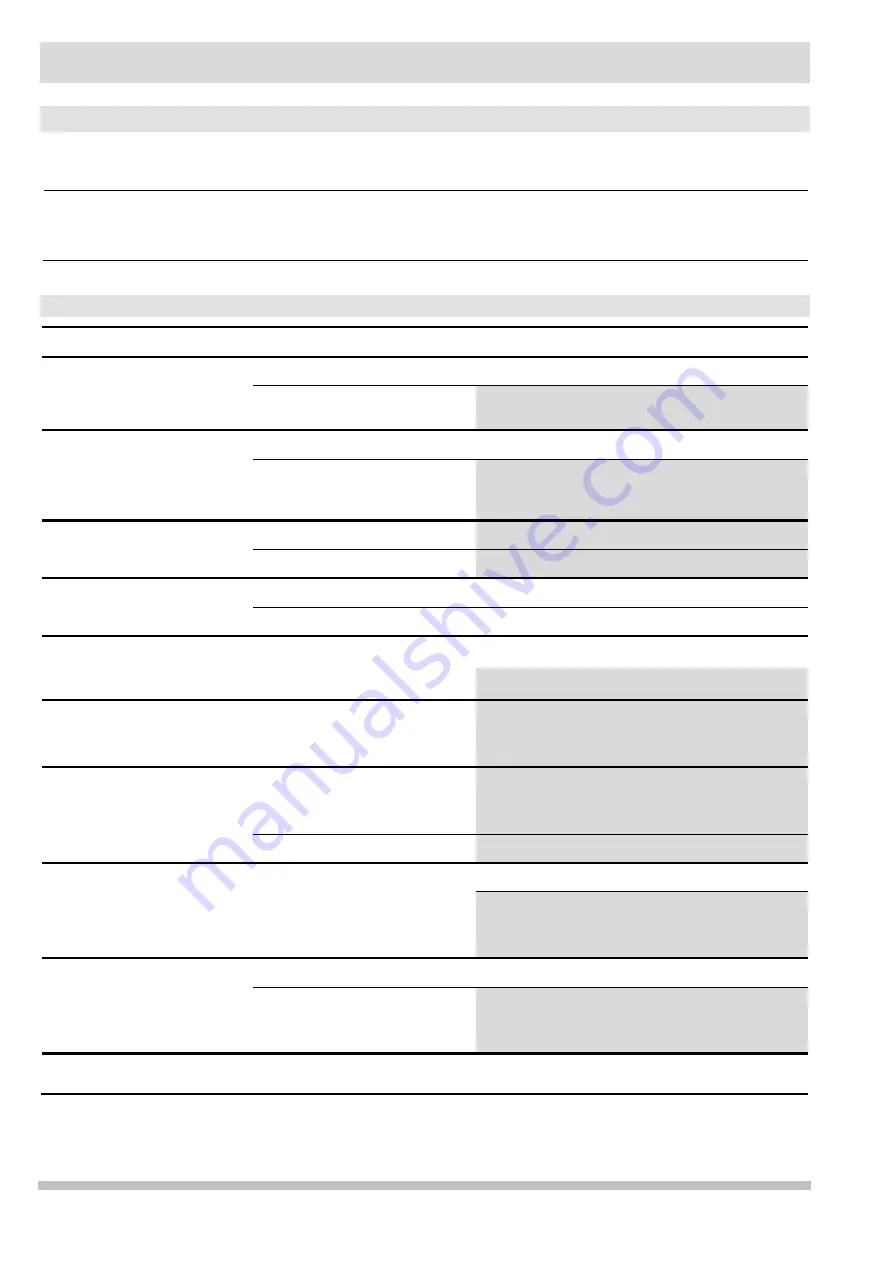

Possible errors

Fault

Description

Machine condition

Solutions

E010

Door open

•

Door open

•

Close door

•

Door closed

•

Check the door lock

•

Check the power cord / plug to the door lock.

E020

EMERGENCY STOP

activated

•

EMERGENCY STOP button pushed

•

EMERGENCY STOP button released

•

EMERGENCY STOP button not

pushed

•

Check the switch of the EMERGENCY STOP button

•

Check the power cord / plug to the EMERGENCY STOP

button.

E025

Door unlocked

•

Door does not engage

•

Check door motor

•

Door engages

•

Check the micro-switch of the door lock

E030

Did not find the

container

•

No mixing container is placed

•

Place mixing container

•

Mixing container is placed

•

The mixing container is too small

E050

Defective container

•

Container is defect

•

Container is unstable

•

Check clamping pressure, if necessary adjust

E150

Error clamp motor

•

The mixing container is not

clamped

•

Check the clamp motor

•

Check the lines to the clamp motor

•

Check the control

E160

Error rotary decoder

•

The mixing unit does not clamp

•

Check clamp motor

•

Check the lines to the clamp motor

•

Check the control

•

The mixing unit clamps

•

Check the control

E170

Error door lock

•

Close door completely

•

Check the door lock

•

Check the connection of the door lock

•

Check door motor

E180

Door is not open

•

The door is not open

•

Open door with the DOOR button

•

The mixing container is clamped

•

Check the door lock

•

Check the connection of the door lock

•

Check door motor

E190

Fuse triggered

•

Turn the machine off and wait one minute until the

fuse can be pushed in again.

The grey highlighted services can only be carried out by trained technicians.