Shaker

V

IBA

15

&

V

IBA

25

Collomix Rühr- und Mischgeräte GmbH

D-85080

Gaimersheim

26

Edition

2.3-05

8.1

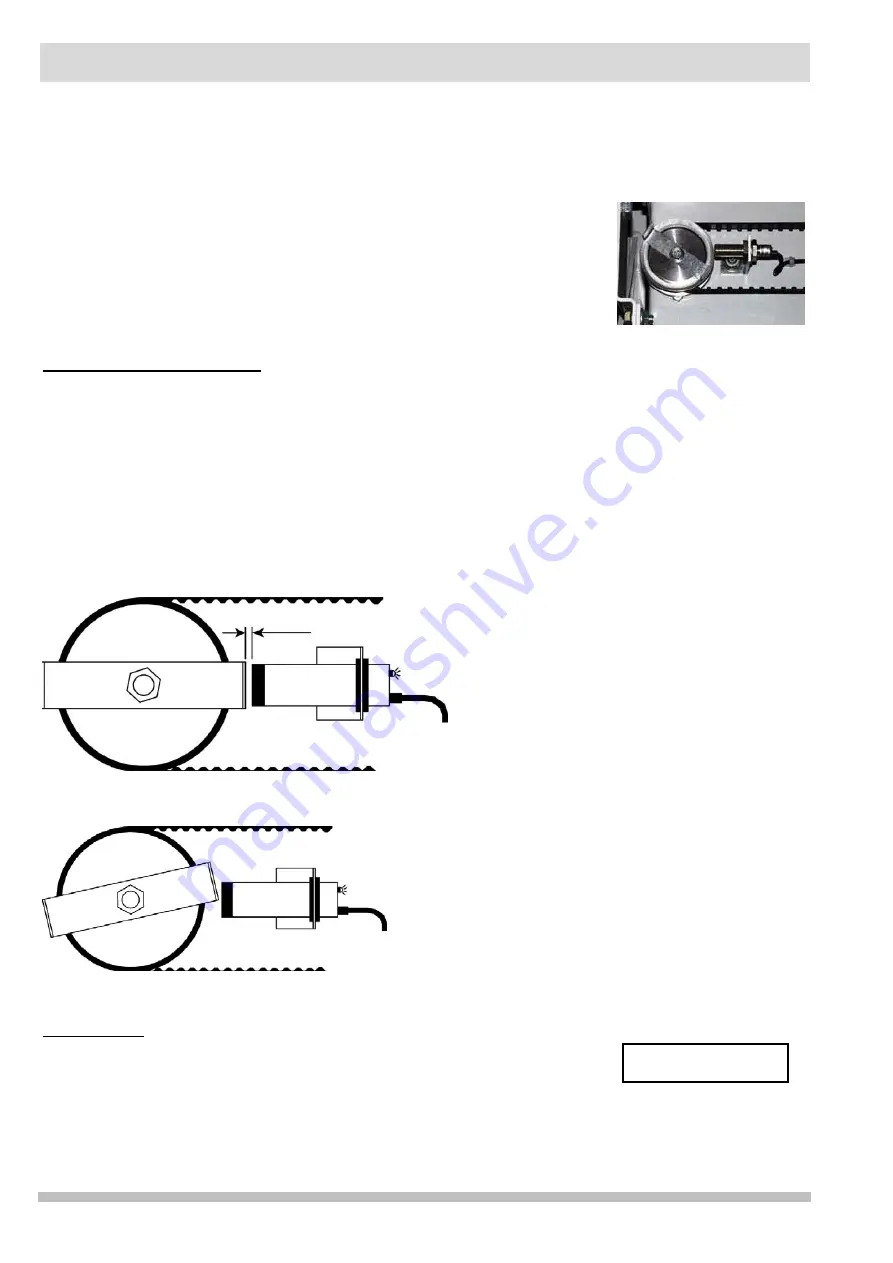

Rotary pulse encoder

*only VIBA 25

The proximity switch (11.370) is fastened by means of a bracket (11.322) to the cross-

member (11.314) (see

Fehler! Verweisquelle konnte nicht gefunden werden.

Fehler! Verweisquelle konnte nicht gefunden werden.

).

The opposite rotary pulse encoder (11.359) transmits two pulses per rotation of the

spindle to the control system. From the number of pulses the control system calculates

the position of the upper clamping plate in order to select high or low pressure.

The proximity switch for the rotary pulse encoder is connected to jumper ST18 on the pcb.

Setting the rotary pulse encoder

Undo the two fastening screws holding the proximity switch.

Turn the rotary pulse encoder until one of its two contact faces is parallel to the end

face of the proximity switch.

Set the proximity switch a distance of approx. 1.5 mm from the rotary pulse encoder.

Fix the proximity switch in place with the two fastening screws.

Turn the rotary pulse encoder and check that it moves smoothly. The rotary pulse

encoder must not rub against the proximity switch.

If the distance between the proximity switch and the rotary pulse encoder is too big,

four pulses instead of two will be recorded. In this case, shorten the distance until only

two pulses per rotation are recorded.

Setting the rotary pulse encoder

Testing that the rotary pulse encoder runs smoothly

INFORMATION

If a defect is discovered on the rotary pulse encoder during initialization, the message

"

only high clamp"

will appear in the display when the initialization routine is completed.

It is then only possible to clamp containers with high clamping pressure.

Rotary pulse encoder

1,5 mm

only high clamp

> call service

LCD display: Rotary

pulse encoder error