Shaker

V

IBA

15

&

V

IBA

25

Collomix Rühr- und Mischgeräte GmbH

D-85080

Gaimersheim

30

Edition

2.3-05

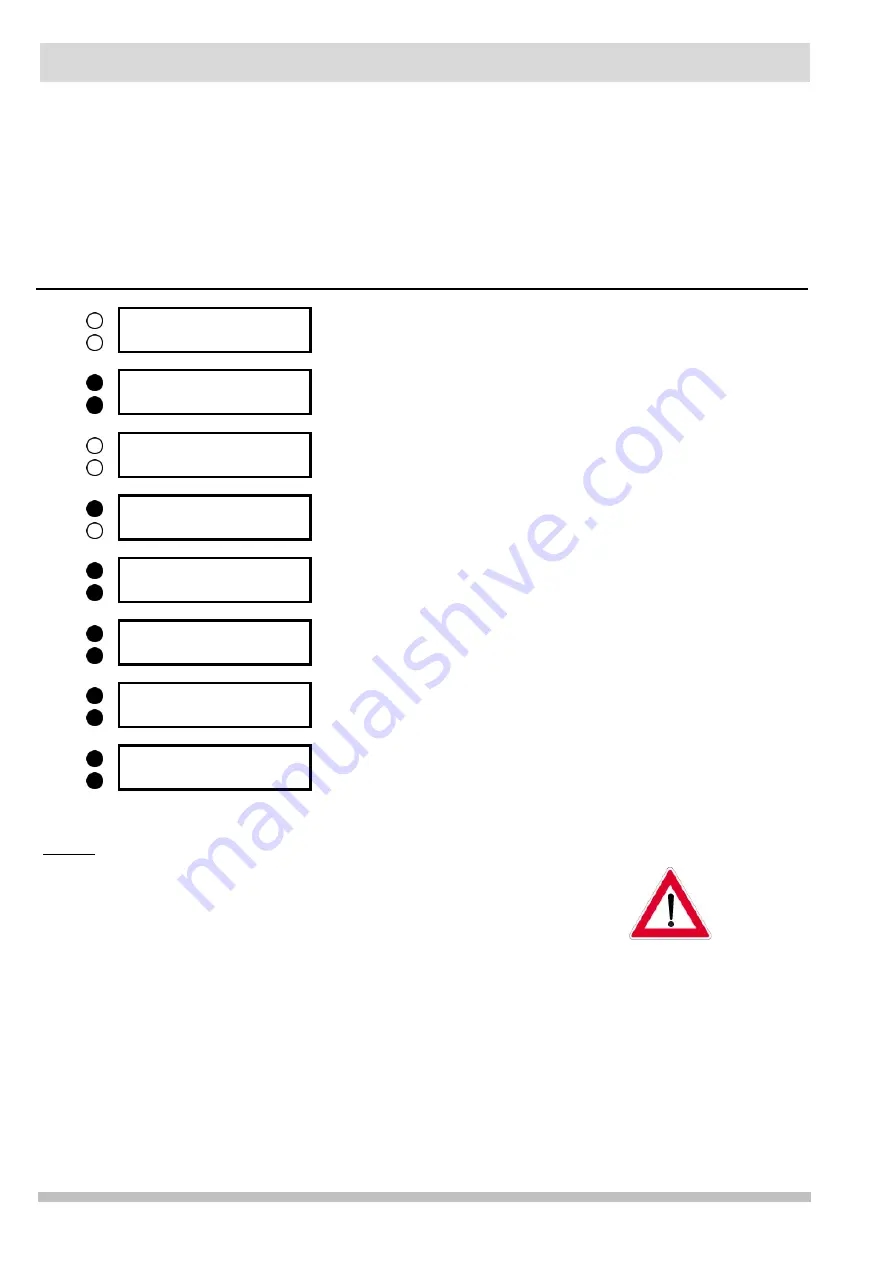

9.2

Initialization

Initialization is performed each time the VIBA Shaker is switched on. The following error messages may appear as a result.

Please note that all maintenance and servicing jobs must be left strictly to authorized and suitably trained personnel.

Caution:

Before you switch on the machine make sure that the door is closed and not unlocked and that the EMERGENCY

STOP button is released!

LEDs

Display

Items to remedy / actions to take

230 V

24 V

empty

•

Check the power supply

•

Check the 230 V fuse

•

Check the connector / cable of the control panel

230 V

24 V

empty

•

Check the connector / cable of the display pcb

•

The display is defective

•

The control pcb is defective

230 V

24 V

Ready

1:00 2:20 3:00

•

Connector for control buttons in wrong position (buttons do not work)

230 V

24 V

Door open

> Close door

•

Check the 24 V fuse

•

Check the connector / cable of the transformer

•

The transformer is defective

230 V

24 V

Door switch fault

> Call Service

•

Check the door interlock system

•

Check the connector / cable of the door interlock system

230 V

24 V

Clamp motor fault

> Call Service

•

Check the clamp motor

•

Check the connector / cable of the clamp motor

•

The control pcb is defective

230 V

24 V

Clamp belt fault

> Call Service

•

Check the clamp belt

•

The threaded spindles have jammed

•

Check the clamp motor / cable – connector

230 V

24 V

Only high clamp

> Call Service

•

Check the rotary encoder

•

Check the connector / cable of the rotary encoder

Caution

All maintenance and servicing jobs must be left strictly to authorized and

suitably trained personnel. This applies in particular to work performed

with the housing open.