Shaker

V

IBA

15

&

V

IBA

25

Collomix Rühr- und Mischgeräte GmbH

D-85080

Gaimersheim

32

Edition

2.3-05

10.

Maintenance and cleaning

Regular inspections, cleaning and maintenance are necessary to ensure that the machine

remains in good working condition at all times.

10.1

Inspections

Check all safety-relevant parts of the machine before beginning with your work. Arrange

for authorized personnel to replace defective or damaged parts before you work again

with the machine.

10.2

Cleaning

If any material escapes from the mixing container when it is inside the machine, remove

it immediately with a rag or a spatula, taking care not to damage any connecting leads

or sensors.

Dirty threaded spindles can be cleaned with a rag or a wire brush. When you have

finished cleaning the threaded spindles, lubricate them again with

Molykote BR 2 Plus

.

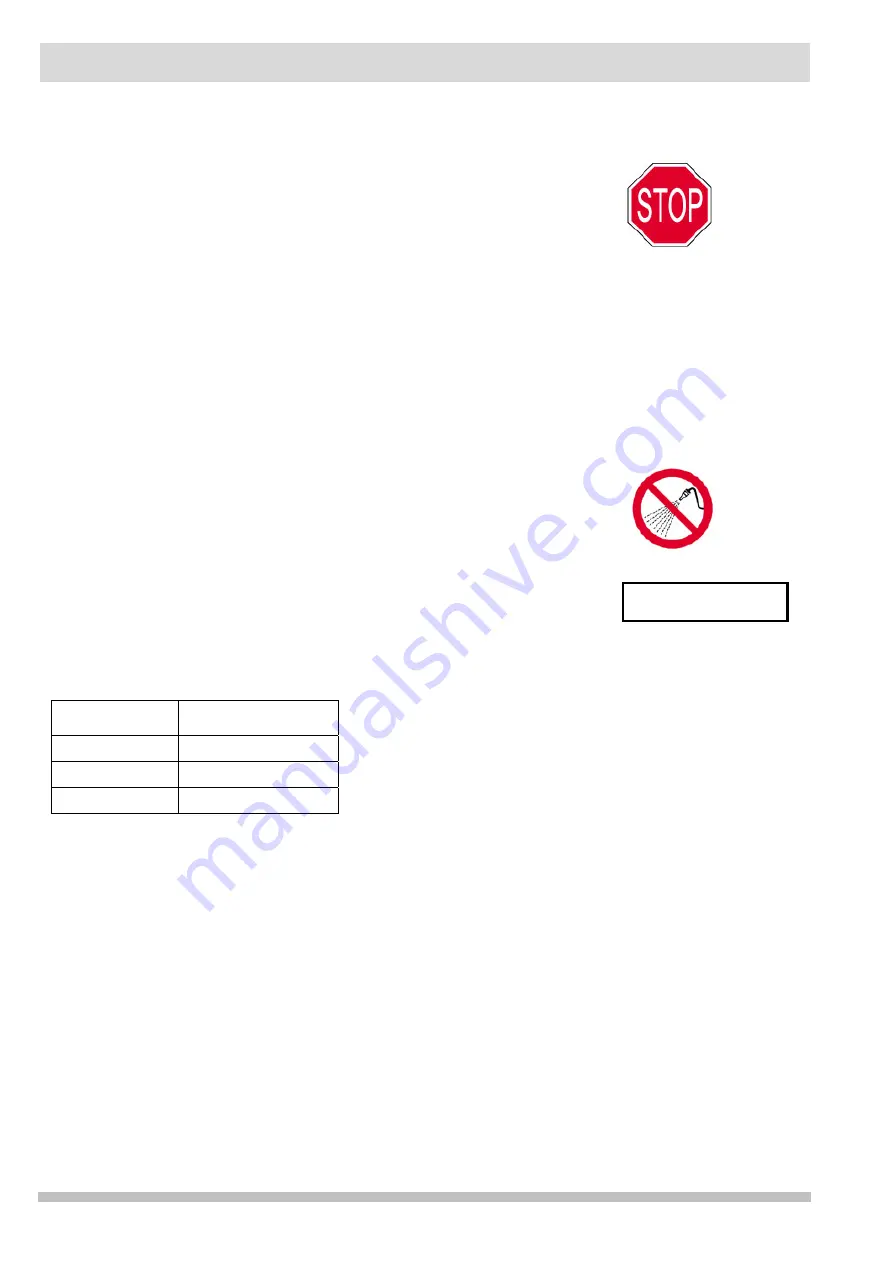

Important!

Never clean the machine with a

high-pressure cleaner

or the like. This

could wash the lubricating grease out of the ball bearings, leaving them to run dry and

resulting in serious damage. Ball bearings which have run dry

must be replaced

immediately!

10.3

Maintenance intervals

Machine maintenance and repair work must be left strictly to authorized personnel. The

extent of the maintenance is described in the servicing plan drawn up for this machine.

How often you repeat the maintenance depends on how intensively the machine is

operated and its average load. The following table provides a guide to the maintenance

intervals.

Average load

Number of cycles

12 kg

10000

20 kg

5000

30 kg

1000

The number of cycles completed so far is indicated in the display after the machine is

switched on. This provides a guide to when maintenance is next due. When the number

of cycles quoted in the table is reached it is time to arrange for maintenance.

Collomix Shaker init

000011 cycles

LCD display:

Number of cycles