Page 9

BRAKE MAINTENANCE

1. Check cables are corrosion free and lubricated to maintain smooth function.

2. Check all cables are free of kinks or frayed section, replace as necessary.

3. From time to time check all the retaining bolts are secure including those

of the pads.

4. Replace lost cable end protectors to avoid cables fraying.

5. To assure smooth braking, wheels must run true and be correctly adjusted, with the

rim brake tracks free from dents and kinks. The brake blocks should be in correct

alignment with the rim brake track. See your dealer if you are in any doubt

regarding wheel and brake adjustment.

6. We recommend that only genuine replacement parts are used for safety critical

components like brake friction pads and cables. if in doubt consult your retailer.

'V' BRAKE ADJUSTMENT

Although every effort has been made to ensure the brakes are set in a manner that

will ensure minimal re-adjustment prior to riding it is not possible to prevent transit

movement or disturbance when unpacking. In addition to the 5mm and 6mm allen key

wrenches and a multi metric spanner included with your cycle you will find the following

tools useful for correct assembly and adjustment of your cycle; a small adjustable wrench

(up to 20mm), a pair of pliers with wire cutting facility, a small cross cut screwdriver, and

a small flat blade screwdriver. For certain maintenance and replacement work specific

cycle tools are needed, if in any doubt contact your cycle supplier.

Below are simple instructions for general brake setting.

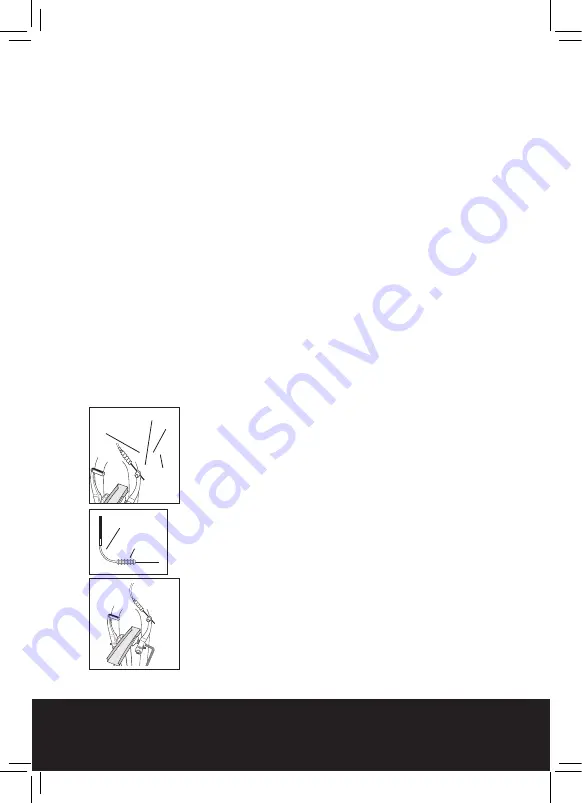

1. If the cable nipple is not located in to its housing in

the lever then simply align the slots in the cable adjuster

with the slot in the brake body and fit the nipple into

the housing. Pull the cable into position through the

slots and turn the adjuster sufficient to disrupt slot

alignment (take care the ferrule is located into the cable

adjuster.)

2. Ensure the fittings (lead pipe and rubber boot) are in

position at the brake end of the cable.

3. Loosen the brake pad retaining nut so the pad can

move freely then push the brake arm so that the pad

can be positioned with its surface parallel to the rim to

keep the pad away from the tyre (Take care to match

the curve of the rim with any curvature along the length

of the pads. Tighten the pad in position (6-8Nm). Repeat

on the left and on the right side.

1.

3.

2.

Nipple

Slot

Lead Pipe

Rubber

Boot

Reach Adjuster

Screw

Ferrule

Page 10

7.

4.

5a.

Brake Pipe

Hanger

Pinch

Bolt

2-3mm

65mm

5b.

Tension

Adjuster

4. Locate the brake cable wire into position behind

the pinch bolt (some have a hole to thread the wire

through). Loosely secure the wire in position.

5. Locate the curved lead pipe into the brake lead

pipe hanger. Loosen the pinch bolt and pull the wire

through so that the pads come into contact with

the rim surface (5a). Set the pads to have 2-3mm

of clearance to the rim on both sides (5b). Tighten

the pinch bolt securely (6-8Nm) and check that the

wire is not damaged or cut through. The distance

between the lead pipe tip and the pinch bolt should

not be less than 65mm. You can exchange positions

of the thick and thin washers behind the pads to

achieve this.

6. Test the brake function, the brake lever should

move through no more than approx 20% - 30% of

its travel before the pads are firmly against the rim.

7. If you find when you pull the brake lever that one

pad hits the rim before the other. You will need to

alter the spring tension in the brake arms. You can

increase spring tension by screwing the adjuster in

clockwise and reduce by turning anti clockwise. The

pad that hits first needs the tension reducing, or you

can increase the tension in the opposing arm ( judge

this by the relative tension adjuster positions). It is

wise to first check that the wheel is centrally located

in the frame or forks before commencing with this

adjustment.

8. New brake cables will stretch; this can be adjusted

by pulling more cable through the pinch bolt or by

using the cable adjuster at the lever. Take care if you

screw the adjuster outwards to return the adjuster

locking ring so it is firmly up against the brake lever

body. IT IS NOT SAFE TO RELY UPON THE THREAD OF

THE LEVER ALONE TO SUPPORT BRAKING FORCES.

Page 9

Page 10

Page 9

BRAKE MAINTENANCE

1. Check cables are corrosion free and lubricated to maintain smooth function.

2. Check all cables are free of kinks or frayed section, replace as necessary.

3. From time to time check all the retaining bolts are secure including those

of the pads.

4. Replace lost cable end protectors to avoid cables fraying.

5. To assure smooth braking, wheels must run true and be correctly adjusted, with the

rim brake tracks free from dents and kinks. The brake blocks should be in correct

alignment with the rim brake track. See your dealer if you are in any doubt

regarding wheel and brake adjustment.

6. We recommend that only genuine replacement parts are used for safety critical

components like brake friction pads and cables. if in doubt consult your retailer.

'V' BRAKE ADJUSTMENT

Although every effort has been made to ensure the brakes are set in a manner that

will ensure minimal re-adjustment prior to riding it is not possible to prevent transit

movement or disturbance when unpacking. In addition to the 5mm and 6mm allen key

wrenches and a multi metric spanner included with your cycle you will find the following

tools useful for correct assembly and adjustment of your cycle; a small adjustable wrench

(up to 20mm), a pair of pliers with wire cutting facility, a small cross cut screwdriver, and

a small flat blade screwdriver. For certain maintenance and replacement work specific

cycle tools are needed, if in any doubt contact your cycle supplier.

Below are simple instructions for general brake setting.

1. If the cable nipple is not located in to its housing in

the lever then simply align the slots in the cable adjuster

with the slot in the brake body and fit the nipple into

the housing. Pull the cable into position through the

slots and turn the adjuster sufficient to disrupt slot

alignment (take care the ferrule is located into the cable

adjuster.)

2. Ensure the fittings (lead pipe and rubber boot) are in

position at the brake end of the cable.

3. Loosen the brake pad retaining nut so the pad can

move freely then push the brake arm so that the pad

can be positioned with its surface parallel to the rim to

keep the pad away from the tyre (Take care to match

the curve of the rim with any curvature along the length

of the pads. Tighten the pad in position (6-8Nm). Repeat

on the left and on the right side.

1.

3.

2.

Nipple

Slot

Lead Pipe

Rubber

Boot

Reach Adjuster

Screw

Ferrule

Summary of Contents for 344/6960

Page 1: ...INSTRUCTION MANUAL HELPLINE CALL FCSI LTD ON 01789 207419 ...

Page 19: ...BIKE CARE Page 18 Page 18 ...

Page 21: ...Page 20 Page 20 Page 20 Page 20 ...

Page 24: ......