5

GENERAL SERVICE:

1.

Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless, and

deadly gas.

2.

Before cleaning, repairing, or inspecting, make certain the

blade(s) and all moving parts have stopped. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3.

Periodically check to make sure the blades come to complete

stop within approximately (5) five seconds after operating the

blade disengagement control. If the blades do not stop within

the this time frame, your unit should be serviced

professionally by an authorized service dealer.

4.

Check brake operation frequently as it is subjected to wear

during normal operation. Adjust and service as required.

5.

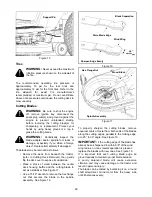

Check the blade(s) and engine mounting bolts at frequent

intervals for proper tightness. Also, visually inspect blade(s)

for damage (e.g., excessive wear, bent, cracked).

Replace the blade(s) with the original equipment

manufacturer’s (O.E.M.) blade(s) only, listed in this manual.

“Use of parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!”

6.

Mower blades are sharp. Wrap the blade or wear gloves, and

use extra caution when servicing them.

7.

Never tamper with the safety interlock system or other safety

devices. Check their proper operation regularly.

8.

After striking a foreign object, stop the engine, disconnect the

spark plug wire(s) and ground against the engine. Thoroughly

inspect the machine for any damage. Repair the damage

before starting and operating.

9.

Never attempt to make adjustments or repairs to the machine

while the engine is running.

10. Grass catcher components and the discharge cover are

subject to wear and damage which could expose moving

parts or allow objects to be thrown.

For safety protection, frequently check components and

replace immediately with original equipment manufacturer’s

(O.E.M.) parts only, listed in this manual. “Use of parts which

do not meet the original equipment specifications may lead to

improper performance and compromise safety!”

11. Do not change the engine governor settings or over-speed the

engine. The governor controls the maximum safe operating

speed of the engine.

12. Maintain or replace safety and instruction labels, as

necessary.

13. Observe proper disposal laws and regulations for gas, oil, etc.

to protect the environment.

WARNING:

YOUR RESPONSIBILITY

Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

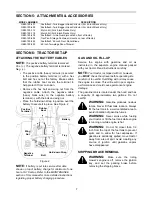

Figure 1 Safety Labels found on your unit

S30011

MAX 20%

S30544