Maintenance & Adjustments

6

13

Maintenance

General Recommendations

•

Always observe safety rules when performing any

maintenance.

•

The warranty on this string trimmer does not cover items

that have been subjected to operator abuse or negligence.

To receive full value from warranty, operator must maintain

the string trimmer as instructed here.

•

Changing of engine-governed speed will void engine

warranty.

•

All adjustments should be checked at least once each

season.

•

Periodically check all fasteners and make sure these are

tight.

WARNING:

Always stop engine, disconnect spark

plug, and ground against engine before performing

any type of maintenance on your machine.

Lubrication

1.

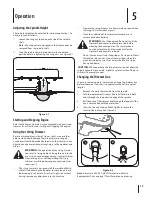

Lubricate pivot points on the control lever at least once a

season with light oil. This control must operate freely in

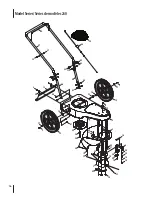

both directions. See Figure 6-1.

Figure 6-1

2.

Lubricate the wheels at least once a season with light oil (or

motor oil). If wheels are removed for any reason, lubricate

surface of the axle bolt and inner surface of the wheel with

light oil. See Figure 6-1.

3.

Follow the accompanying engine manual for lubrication

schedule and instruction for engine lubrication.

Deck Care

Clean underside of the machine after each use to prevent build-

up of grass clippings or other debris. Follow steps below:.

1.

Disconnect spark plug wire. Drain gasoline from string

trimmer or place a piece of plastic under the gas cap.

2.

Tip trimmer so that it rests on its side. Keep the side with

the air cleaner facing up. Hold trimmer firmly.

WARNING:

Never tip the trimmer more than 90º in

any direction and do not leave the trimmer tipped

for any length of time. Oil can drain into the upper

part of the engine causing a starting problem.

3.

Scrape and clean the underside of the machine with a

suitable tool. Do not spray with water.

IMPORTANT:

Do not use a pressure washer or garden hose

to clean the machine. These may cause damage to the

engine. The use of water will result in shortened life and

reduce serviceability.

4.

Put the trimmer back on its wheels on the ground. If you

had put plastic under the gas cap earlier, make sure to

remove it now.

Engine Care

A list of key engine maintenance jobs required for good

performance by the trimmer is given below. Follow the

accompanying engine manual for a detailed list and instructions.

•

Maintain oil level as instructed in engine manual.

•

Service air cleaner every 25 hours under normal conditions.

Clean every few hours under extremely dusty conditions.

Poor engine performance and flooding usually indicates

that the air cleaner should be serviced. To service the air

cleaner, refer to the engine manual.

•

Clean spark plug and reset the gap once a season. Spark

plug replacement is recommended at the start of each

mowing season. Check engine manual for correct plug

type and gap specifications.

•

Clean engine regularly with a cloth or brush. Keep the

top of the engine clean to permit proper air circulation.

Remove all grass, dirt and debris from muffler area.

•

Engines stored between 30 and 90 days need to be treated

with a gasoline stabilizer such as

STA-BIL®

to prevent

deterioration and gum from forming in fuel system or on

essential carburetor parts.

Off-Season Storage

•

Refer to engine manual for specific engine storage

instructions

•

Clean and lubricate trimmer.

•

Store trimmer in a dry, clean area. Do not store next to

corrosive materials, such as fertilizer.

•

Using a light oil or silicone, coat the equipment, especially

cables and all moving parts of your string trimmer.

Summary of Contents for 260 series

Page 15: ...Notes 15 ...