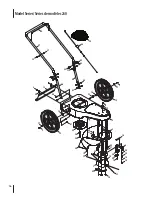

17

25A-262J

10.29.14

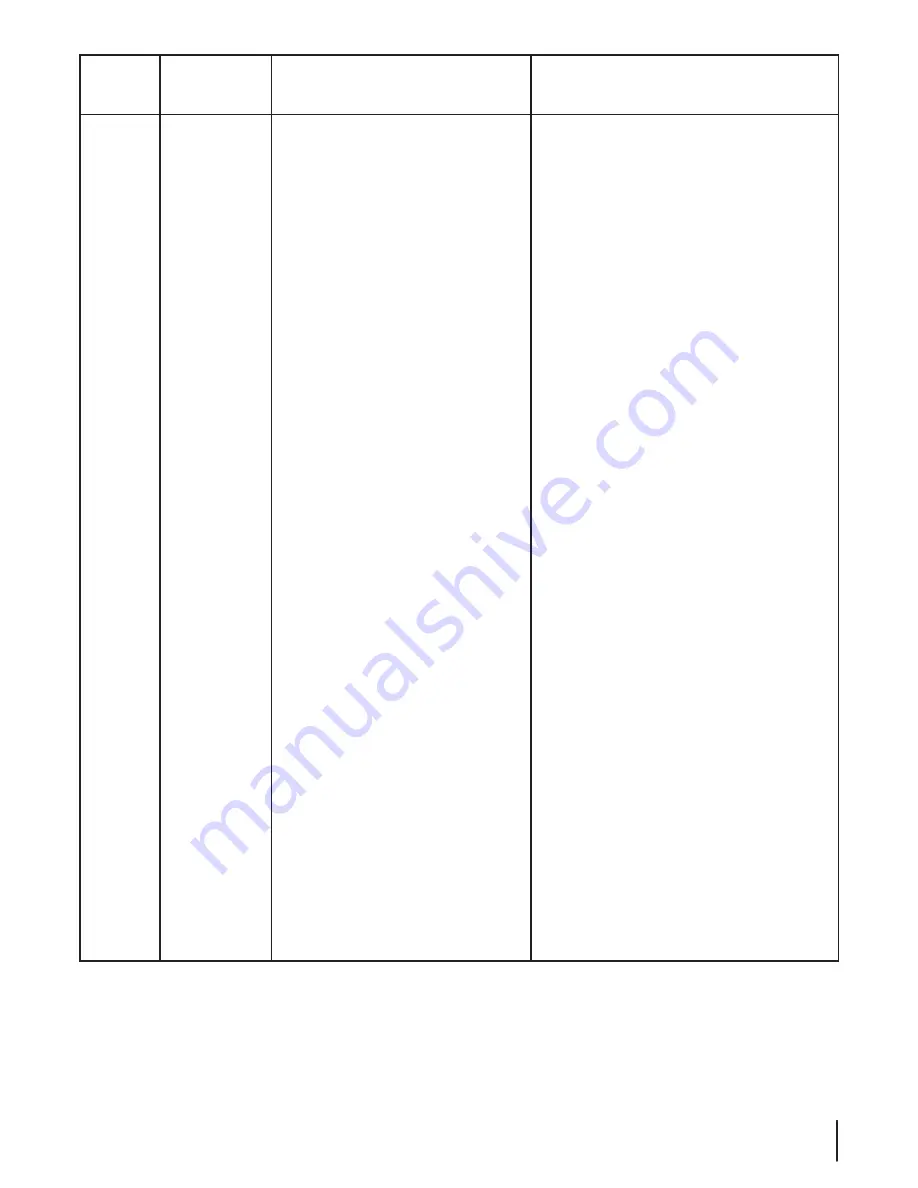

Ref. No.

No. de

Réf.

Part No.

No. de

pièce

Description

Description

1

618-07086

Spindle Assembly

Ensemble de fusée

2

631-0096

Deflector Assembly, Trimmer

Déflecteur de la tondeuse à fil (Comprend les

(incl. Deflector Flap and Hardware)

déflecteur et boulonnerie)

3

681-0159

Axle Assembly, Trimmer

Essieu de la tondeuse à fil

4

681-0181A

Bracket Assembly, Idler Trimmer

Support de la tondeuse à fil

5

681-05007A

Deck Assembly, Trimmer

Corps de la tondeude à fil

6

710-0237

Hex Screw 5/16-24, .625, Gr. 5, Std

Vis à tête hex. 5/16-24 x 0,625 Qual. 5

7

710-0703

Carriage Bolt 1/4-20, .75, Gr. 5

Boulon ordinaire 1/4-20 x 0,75

8

710-1652

Self-Tapping Screw 1/4-20 x .625

Vis taraudée 1/4-20 x 0.625

9

710-3015

Hex Screw, 1/4-20, .75, Gr. 5, Std

Vis à tête hex. 1/4-20 x 0,75 Qual. 5

10

712-04063

Flange L-Nut 5/16-18, Gr. F

Contre-écrou à embase 5/16-18, Gr. F

11

712-04064

Flange L-Nut 1/4-20, Gr. F

Contre-écrou à embase 1/4-20, Gr. F

12

734-04030

Wheel 14 x 1.75, Gray

Roue 14 x 1,75, gris

13

731-2329

Trailshield 5.85 x 14.50

Déflecteur arrière

14

732-1022

Spring, Extension, .50 OD x 3.375

Ressort d’extension 0,50 dia. x 3,375 po de lg.

15

736-0173

Flat Washer .280 x .740 x .063

Rondelle plate 0,280 x 0,740 x 0,063

16

736-0182

Spring Washer .500 x 1.00 x .022

Rondelle ressort 0,50 x 1,0 x 0,022

17

736-0270

Cupped Washer .265 x .750 x .060

Rondelle creuse 0,265 x 0,75 x 0,060

18

736-0371

Flat Washer .343 x .880 x .062

Rondelle plate 0,343 x 0,880 x 0,062

19

736-0425

Cupper Washer .325 x .930 x .045

Rondelle creuse 0,325 x 0,930 x 0,045

20

731-2315

Deflector

Déflecteur

21

490-040-M035

Line, Trimmer .155, 10-pack

Fil de coupe de 0,155 po de diamètre

22

748-0278

P/M Spacer

Entretoise

23

750-1240

Spacer .51 ID x 1.00 OD x .38

Entretoise 0,51 ID x 1,00 OD x 0,38

24

750-1275

Idler Spacer

Entretoise

25

754-05077

V-Belt

Courroie trapézoïdale

26

756-05108

Idler Pulley

Poulie de tension

27

781-1020

Keeper Bracket, Front

Support du guide de courroie avant

28

781-1028

Keeper Bracket, Idler

Support du guide de la poulie de tension

29

782-9065

Hinge Clip, Trailshield

Attache du déflecteur arrière

30

710-1823

Screw, HL #12-16 x .625

Vis H-Low no. 12-16 x 0.625

31

736-0400

Flat Washer .194 x .62 x .063

Rondelle plate 0,194 x 0,62 x 0,063

32

656-05000

Pulley/Flywheel

Poulie/volant

33

710-0654A

Sems Screw 3/8-16 x 1.0

Vis Sems 3/8-16 x 1,0

34

710-06074

Hex Screw 3/8-24 x 1.25 Gr8

Vis à tête hex. 3/8-24 x 1,25 Qual. 5

35

731-09688

Cover, Shroud

Capot

36

736-0452

Cupped Washer .396 x 1.14 x .095

Rondelle creuse 0,396 x 1,14 x 0,095

37

720-0279

Knob, Handle

Bouton

38

710-04998

Carriage Bolt 5/16-18, 1.00 Gr. 5

Boulon ordinaire 5/16-18 x 1,0 Qual. 5

39

710-1205

Eye Bolt 1/4-20

Boulon de guidage de cordon 1/4-20

40

710-3005

Hex Screw 3/8-16 x 1.25 Gr. 5, Std

Vis à tête hex. 3/8-16 x 1,25 Qual. 5

41

712-04065

Flange L-Nut 3/8-16, Gr. F

Contre-écrou à embase 3/8-16 Qual. F

42

720-04122

Wing Knob 5/16-18 Black

Bouton 5/16-18 Noir

43

738-04419A

Shoulder Screw .375 x .148 x 1/4-20

Vis à épaulement 0,375 x 0,148 x 1/4-20

44

746-05141

Control Cable, 48”

Câble de la commande, 48 po

45

747-06246

Control Lever

Levier de la commande

46

749-05102

Handle, Lower

Guidon, inférieur

47

749-05103

Handle, Upper

Guidon, supérieur

—

723-0400

Safety Glasses

Lunettes de sécurité

Summary of Contents for 260 series

Page 15: ...Notes 15 ...