13

CHIMNEY AND VENT PIPE CONNECTION

WARNING

Installing or venting a boiler or any other gas

appliance with improper methods or materials could

result in death or serious injury due to

fi

re or to

asphyxiation from poisonous gases such as carbon

monoxide which is odorless and invisible.

!

Boiler and venting installations shall be performed

in accordance with "Venting of Equipment", of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or

applicable provisions of the local building codes.

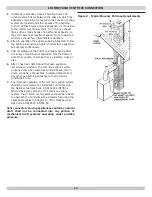

Chimney Inspection

Chimney must be clean, right size, properly constructed

and in good condition.

Installation must conform to requirements of the authority

having jurisdiction or, in absence of such requirements, to

the National Fuel Gas Code, ANSI Z223.1/NFPA 54. See

Figure 9, page 14.

Connecting Vent Damper and Vent Connector

Vent or vent connector shall be Type B or metal pipe

having resistance to heat and corrosion not less than that

of galvanized sheet steel not less than No. 26 gauge. See

Table 1 for size of vent (

fl

ue opening).

1.

Position furnished vent damper on top of

fl

ue outlet

collar. Fasten damper securely to

fl

ue outlet collar with

sheet metal screws.

• Verify 1/2 square inch (approximately 3/4" diameter)

hole in damper blade is plugged using plug supplied

with vent damper.

• Verify damper blade has clearance to operate inside

of diverter.

• Do not modify draft diverter or vent damper.

2.

Install vent damper to service only single boiler for

which it is intended.

• Damper position indicator shall be in visible location

following installation.

• Locate damper so it is accessible for servicing.

Optional -

damper may be installed in horizontal or

vertical position as close to

fl

ue outlet as possible.

• Horizontal installations. See Figure 10, page 15.

• Alternate installations

see steps below. See Figure 11

page 15.

A. Do not install vent damper on vent pipe curve.

B. Do not run wires near high temperature surfaces.

Use stand-off brackets

if necessary.

3.

Damper must be in open position when appliance main

burners are operating.

4.

Boiler is equipped with factory wired harness that plugs

into vent damper. Connect thermostat to orange and

white wires marked 24 volt thermostat on boiler.

5.

Vent pipe must be same size as

fl

ue outlet collar.

6.

Slope pipe up from boiler to chimney not less than 1/4”

per foot.

7.

Run pipe as directly as possible with as few elbows as

possible.

8.

Do not connect to

fi

replace

fl

ue.

9.

End of vent pipe must be

fl

ush with inside face of

chimney

fl

ue.

10.

Horizontal run should not be longer than 3/4 the

chimney height (HT).

See Figure 9 page 14.

Vent Pipe

• Fasten sections of vent pipe with 3 sheet metal screws

at each joint to make piping rigid.

• Support horizontal portions of vent system to prevent

sagging.

• Use stovepipe wires or metal strapping every 5’ to

support pipe from above.

• Vent pipe through crawl space, use double wall vent

pipe.

• Vent pipe passing through combustible wall or partition,

use ventilated metal thimble. Thimble should be 4"

larger in diameter than vent pipe.

NOTICE

Minimum Vent Pipe Clearance - Wood and other

combustible materials must not be closer than 6”

from any surface of single wall metal vent pipe.

Listed Type B vent pipe or other listed venting

systems shall be installed in accordance with their

listing.

Removing Existing Boiler from Common Venting

System

When an existing boiler is removed from a common

venting system, the common venting system is likely to be

too large for proper venting of the appliances remaining

connected to it.

At the time of removal of an existing boiler, the following

steps shall be followed with each appliance remaining

connected to the common venting system placed in

operation, while the other appliances remaining connected

to the common venting system are not in operation.

1.

Seal any unused openings in the common venting

system.

2.

Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and other de

fi

ciencies

which could cause an unsafe condition.