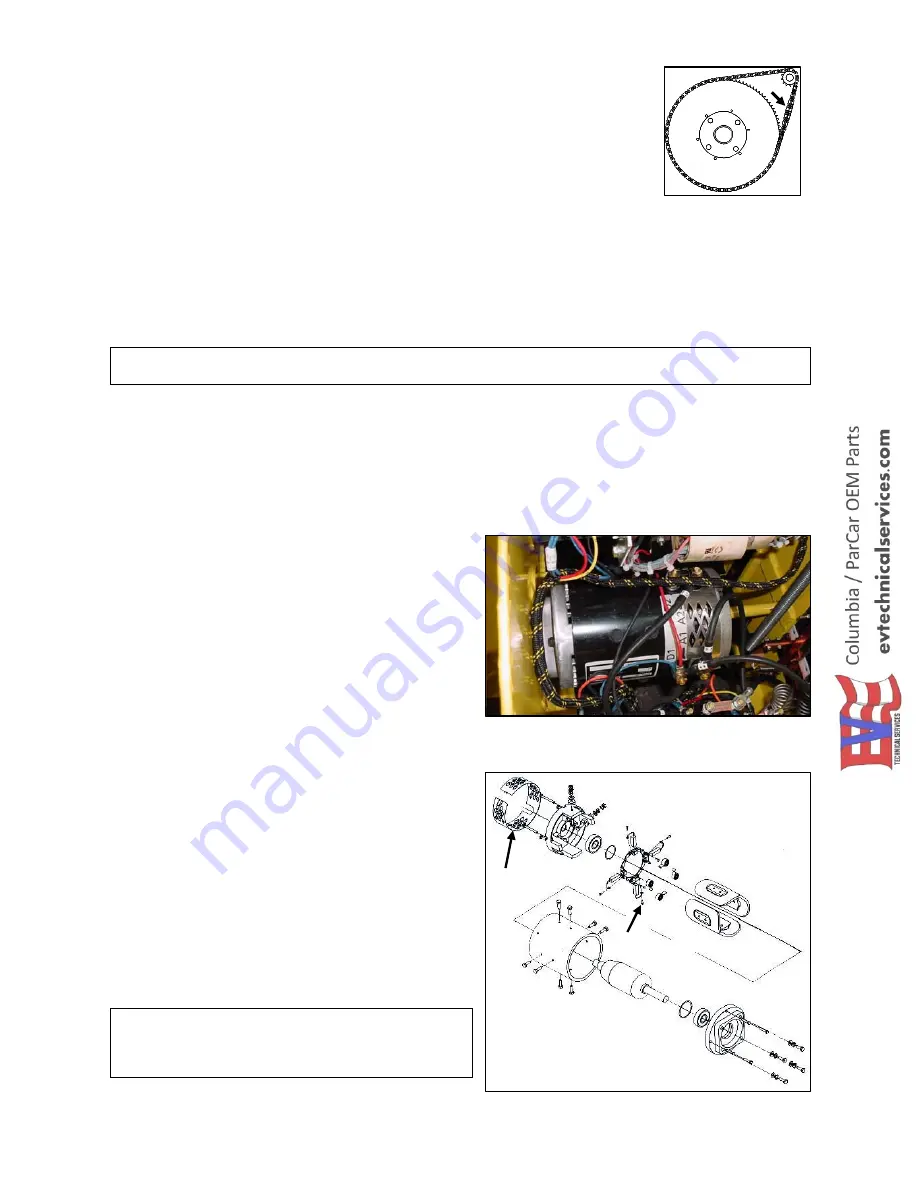

Figure 4.5.1

Figure 4.5.2

Tension Adjustment:

Lift the rear of the vehicle and remove the drive wheel.

Loosen the 4 drive motor mounting bolts (Fig. 4.4.2) and jam nut on the drive

motor adjusting screw. Turning motor adjusting screw towards motor will

tighten drive chain. Turning adjusting screw away from motor will loosen

drive chain. With motor mounting bolts tight, proper chain deflection is no

more than 0.50' (1/2 inch). See arrow Fig. 4.4.3.

Torque motor mounting bolts to 150 inch pounds and tighten the jam nut

(Fig. 4.4.1 B) on motor adjusting screw.

Install drive wheel.

4.5 DRIVE MOTOR

To remove the drive motor (Figure 4.5.1):

Remove the charger cover plate.

Disconnect the wires from the motor, noting their locations for reinstallation.

NOTICE:

T

o avoid possible internal motor damage when removing or installing cables, use a

wrench to hold the bottom nut and stud for loosening or tightening the top nut.

Lift the rear of the vehicle and remove the rear drive wheel.

Loosen the four motor mounting bolts (Fig. 4.4.2) and nut on the motor adjusting bolt (Fig. 4.4.1).

Loosen the motor adjusting screw several turns.

Slide the motor toward the rear of the vehicle and remove the drive chain.

Support the motor and remove the four mounting bolts.

Slide the motor to the left until the drive sprocket is clear of the frame and lift the motor up from the

vehicle.

To install drive motor:

Place the motor in the frame with the wire

terminals as shown in Figure 4.5.1.

Once in place, install the top motor mounting bolt

first, then install the remaining three motor

mounting bolts (Fig. 4.4.2). Do not tighten.

Install the drive chain and adjust as stated in

Section 4.4.

Install the rear drive wheel. Torque wheel nuts in

a crossing pattern, to 65-ft. lbs.

Connect the wire leads to the motor.

To remove and install motor brushes (Fig. 4.5.2):

Remove motor as described above and remove

the inspection headband (A).

For each brush, remove the screw (B) from the

brush lead, pull the brush spring away from the

brush and remove the brush.

To install, pull brush spring away from the brush

holder, set the brush in the brush holder and

release spring.

Install screw into the brush lead.

Install the inspection headband and replace

motor.

NOTICE:

Minimum brush length is 0. 50" (1/2

inch). Whenever possible, always re-surface

armature commutator when installing new

brushes.

A

B

4-4

Figure 4.4.3

Summary of Contents for CR-10 Chariot

Page 1: ......