LWLCWH COLUMBIA BOILER COMPANY REV. 13106

11

FUEL CONNECTIONS

OIL SUPPLY PIPING

Connect burner to oil supply. Refer to fuel unit manufacturer literature for piping, connections, lift and

tank installation. If such information is unavailable use the following guidelines:

Fuel supply “level with” or “above” burner: A single stage fuel unit connected to the fuel supply

with a single supply line is the most common type of installation for these conditions. Manual vent-

ing of the fuel oil is usually required on initial start up. Failure to vent air could result in air lock/oil star-

vation.(One Pipe)

Fuel supply below the level of the burner: Use a single stage fuel pump in lift conditions of up to

10 feet and a two stage pump when lift exceeds 10 feet. Both conditions require the use of a return

line which purges the fuel pump of air, returning it to the fuel tank. The by-pass plug must be insert-

ed into the fuel pump when installing a return line.(Two Pipe)

Fuel line installation: Consult the burner section of this manual for oil line type and sizing require-

ments for proper operation. The size of oil lines is extremely important for proper operation.

Continuous lengths of heavy wall copper tubing are recommended and should be installed under the

floor whenever possible. Fuel lines should not chaff the appliance or building structure.

All oil feed lines must be air tight. Use as few fittings as possible when assembling the oil lines.

Compression fittings allow more of a chance for air to be introduced into the oil supply. The slightest

air leak, usually caused by loose fittings or bad gaskets, can cause poor starts, smoky starts, soot-

ing of burner parts, inefficient operation, and a dangerous combustion condition. Always install fittings

in accessible locations.

WARNING:

TEFLON

®

TAPE SHOULD NEVER BE USED WITH ANY OIL LINE CONNECTIONS.

THE USE OF TEFLON

®

TAPE ON BURNER COMPONENTS OR OIL SERVICE LINES

WILL VOID MOST BURNER WARRANTIES.

A vacuum test should be done on all installations to ensure that all fittings are tight and the oil lines

are of proper size. Suction vacuums must be held to acceptable limits.

Fuel line valve and filter: (Not supplied) Install two high quality shutoff valves in accessible locations

on the oil supply line. Locate one close to the tank and the other close to the burner ahead of the fil-

ter. Some filters come with built-in shutoff valves. Install a generous capacity filter inside the building

between the fuel tank shutoff and burner.

For additional information consult the burner section of this manual.

Summary of Contents for CWH series

Page 2: ......

Page 34: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 31 ...

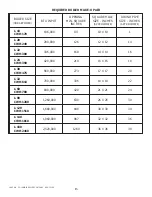

Page 35: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 32 SPECIFICATIONS AND DATA ...

Page 36: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 33 ...

Page 37: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 34 ...

Page 38: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 35 ...

Page 39: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 36 SPECIFICATIONS AND DATA 14 2 ...

Page 45: ...42 ...

Page 46: ...43 ...

Page 47: ...44 ...

Page 48: ...45 ...

Page 49: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 46 ...

Page 50: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 47 ...

Page 51: ...48 ...

Page 52: ...49 ...

Page 53: ...50 ...

Page 54: ......

Page 55: ......