LWLCWH COLUMBIA BOILER COMPANY REV. 13106

24

MAINTENANCE

RECORD KEEPING

All manufacturers literature, spare parts lists, operating and maintenance procedures should be main-

tained in the boiler room at all times. A log book should also be provided to record maintenance work,

inspections, and other performance test results.

General

Clean the boiler and heating surfaces whenever required. The frequency of the cleaning required to

maintain the boiler at peak efficiency will be determined only by frequent inspections. It cannot be

predicted. Your operating conditions might be different from your neighbors .

When in doubt - check it out.

WARNING:

DISCONNECT ALL INCOMING ELECTRICAL POWER BEFORE SERVICING THE

BOILER. USE EXTREME CAUTION AROUND BOILER PIPING THE LOW WATER

CUT OFFS, SINCE THEY MAY BE VERY HOT.

The life of your boiler will be determined by the level of care given it by those who are responsible

for maintenance. A log of the following items should be maintained in the boiler room at all times.

Daily Boiler Check & Maintenance List

1.

Water Level Controls and Cut Offs are operating normally.

2.

Instrument and equipment settings are normal.

3.

Gauge glass is clean. If leaks are detected, replace glass, gaskets, and brass washers

immediately. When replacing gauge glass use only 5/8" O.D. Pyrex

®

red line, high

pressure, high temperature, glass tubing, with fire polished ends. See gauge glass

maintenance section for proper method when installing this gauge glass.

4.

Boiler water at proper operating level.

5.

Blow down boiler as instructed under BLOWDOWN if required by application.

Remember, the life of your boiler is drastically reduced by sludge, scale, and corrosion. By proper

treatment of the boiler water and systematic blow down procedures your boiler will provide years of

service.

Weekly Boiler Check & Maintenance List

1.

Check flame failure detection system.

A. Gas boilers: Close fuel supply to pilot and main gas and check shut down timing.

B. Oil boilers: Remove cad cell leads and check shut down timing.

2.

Check fuel valves; Open limit switch and make aural and visual check.

3.

Check ignition system flame signal.

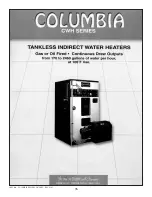

Summary of Contents for CWH series

Page 2: ......

Page 34: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 31 ...

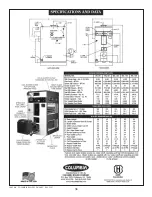

Page 35: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 32 SPECIFICATIONS AND DATA ...

Page 36: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 33 ...

Page 37: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 34 ...

Page 38: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 35 ...

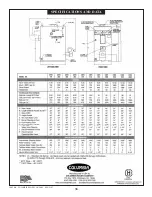

Page 39: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 36 SPECIFICATIONS AND DATA 14 2 ...

Page 45: ...42 ...

Page 46: ...43 ...

Page 47: ...44 ...

Page 48: ...45 ...

Page 49: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 46 ...

Page 50: ...LWLCWH COLUMBIA BOILER COMPANY REV 3107 47 ...

Page 51: ...48 ...

Page 52: ...49 ...

Page 53: ...50 ...

Page 54: ......

Page 55: ......