22

•

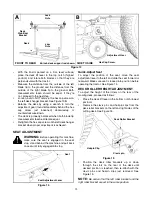

Push the oil drain valve in slightly, then rotate

counterclockwise and pull outward to begin

draining oil. See Figure 19.

•

Service the

oil filter

(if so equipped)

as instructed

in the separate engine manual packed with your

unit.

Perform the above steps in the opposite order after oil

has finished draining.

•

Refill the engine with new motor oil.

IMPORTANT:

Refill the engine with the proper

capacity and weight of motor oil as instructed in the

separate engine manual.

Service

air cleaner

every 25 hours under normal

conditions. Clean every few hours under extremely

dusty condition. To service the air cleaner, refer to the

separate engine manual packed with your unit.

The

spark plug(s)

should be cleaned and the gap reset

once a season. Spark plug replacement is

recommended at the start of each mowing season;

check engine manual for correct plug type and gap

specifications.

SECTION 9: LUBRICATION

WARNING:

Before lubricating, repairing,

or inspecting, always disengage PTO, move

shift lever into neutral position, set parking

brake, stop engine and remove key to prevent

unintended starting.

Engine

Lubricate the engine with motor oil as instructed in the

Engine

Owner’s Manual packed with your unit.

Pivot Points & Linkage

Lubricate all the pivot points on the drive system,

parking brake and lift linkage at least once a season

with light oil.

Transmission

The hydrostatic transmission is sealed at the factory.

Oil level cannot be checked nor can the oil be changed.

Front Wheels

Each of the front wheel axles is equipped with a grease

fitting. Lubricate with a grease gun after every 25 hours

of tractor operation.

Rear Wheels

The rear wheels should be removed from the axles

once a season. Lubricate the axles and the rims well

with an all-purpose grease before re-installing them.

SECTION 10: SERVICE

TIRES

WARNING:

Never exceed the maximum

inflation pressure shown on the sidewall of

the tire.

The recommended operating tire pressure is 10 psi for

the rear tires and 14 psi for the front tires. Refer to the

tire sidewall for exact tire manufacturer’s recommended

or maximum psi. Do not overinflate. Uneven tire

pressure could cause the cutting deck to mow

unevenly.

CUTTING BLADES

WARNING:

Be sure to shut the engine off,

remove ignition key, disconnect the spark

plug wire(s) and ground against the engine to

prevent unintended starting before removing

the cutting blade(s) for sharpening or

replacement. Protect your hands by using

heavy gloves or a rag to grasp the cutting

blade.

WARNING:

Periodically inspect the blade

adapter and/or spindle for cracks or damage,

especially if you strike a foreign object.

Replace immediately if damaged

.

The blades may be removed as follows.

•

Remove the deck from beneath the tractor, (refer to

DECK REMOVAL) then gently flip the deck over to

expose its underside.

•

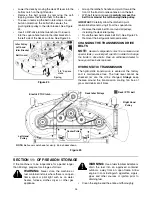

Place a block of wood between the center deck

housing baffle and the cutting blade to act as a

stabilizer. See Figure 20.

•

Use a 15/16" wrench to remove the hex flange nut

that secures the blade to the spindle assembly. See

Figure 20.

To properly sharpen the cutting blades, remove equal

amounts of metal from both ends of the blades along

the cutting edges, parallel to the trailing edge, at a 25°

to 30° angle. See Figure 21.

IMPORTANT:

If the cutting edge of the blade has

already been sharpened to within 5/8" of the wind wing

radius, or if any metal separation is present, replace the

blades with new ones. See Figure 21.