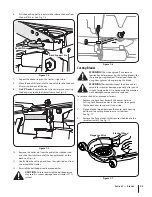

Drive Belt (Mowing Deck) 50” Deck

954-04077

Deck Blade 2 in 1

942-04053C

Deck Spindle

918-04125B

Front Deck Wheel

734-04155

Rear Deck Wheel

734-0973

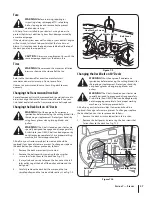

Batterie

925-1707D

Fuel Tank Cap

951-12182

Throttle/Choke Control Cable

746-04542

Ignition Key

925-1745A

Discharge Chute Assembly

631-04092B

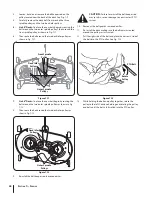

Replacement Parts

31

Summary of Contents for Hydrostatic Lawn Tractor

Page 36: ...36 Notes ...