S

ection

6 — M

aintenance

& a

djuStMentS

21

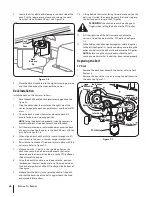

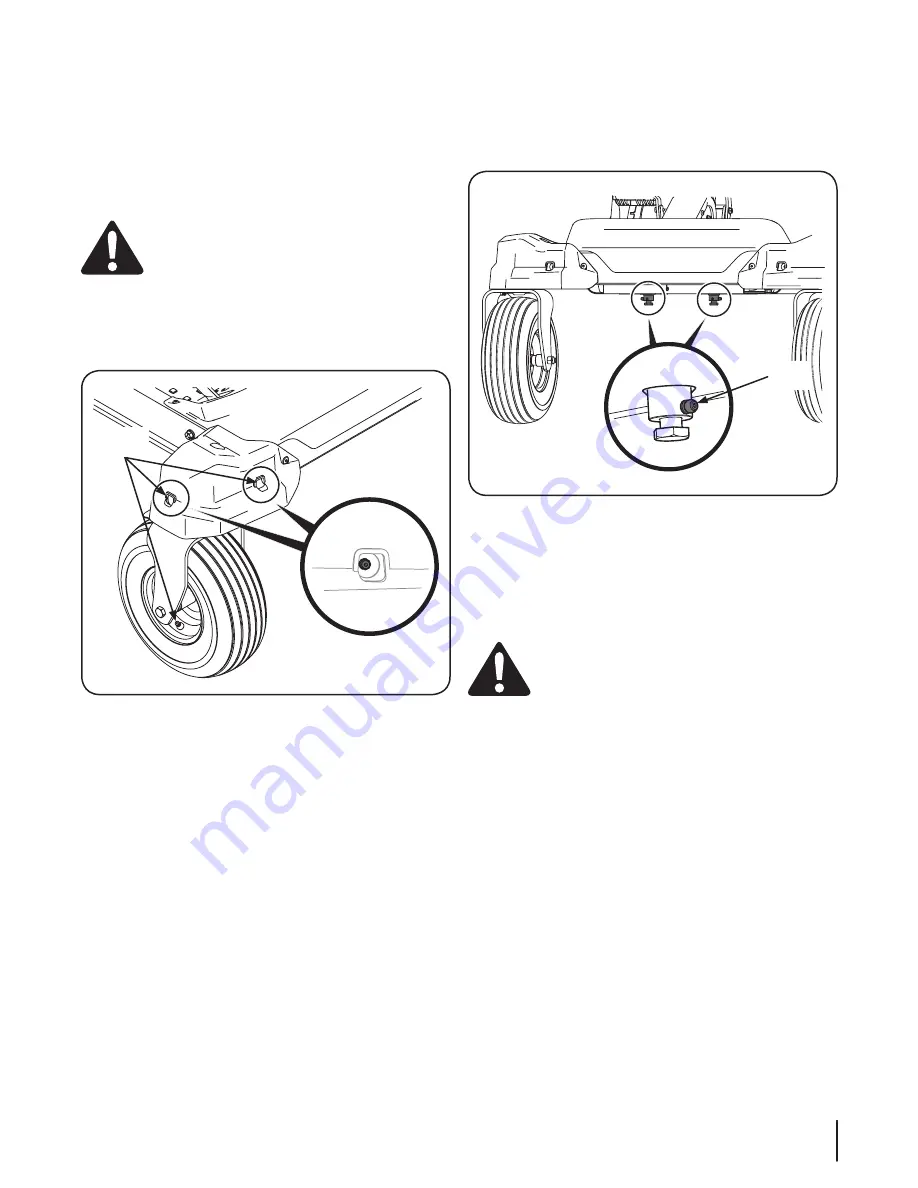

Steering Supports

Under the frame of the tractor there are two grease fittings for

the steering supports. Lubricate with a No. 2 multi-purpose

grease applied with a grease gun after every 25 hours of tractor

operation. See Figure 6-3.

Grease

Fitting

Figure 6-3

Tires

Check the tire air pressure after every 50 hours of operation or

weekly. Keep the tires inflated to the recommended pressures.

Improper inflation will shorten the tire service life. See the tire

side wall for proper inflation pressures. Observe the following

guidelines:

WARNING!

Never exceed the maximum inflation

pressure shown on the sidewall of the tire.

Do not reinflate a tire that has been run flat or seriously under

inflated. Have it inspected and serviced by a qualified tire

mechanic.

10. Turn the water off and detach the hose coupler from the

water port on your deck’s surface.

11. After cleaning your deck, return to the operator’s position

and engage the PTO. Keep the cutting deck running for a

minimum of two minutes, allowing the underside of the

cutting deck to thoroughly dry.

Lubrication

WARNING!

Before lubricating, repairing, or

inspecting, always disengage PTO, set parking

brake, stop engine and remove key to prevent

unintended starting.

Front Wheels

Each of the front wheel spindles and rims is equipped with a grease

fitting. See Figure 6-2. Lubricate with a No. 2 multi-purpose grease

applied with a grease gun after every 25 hours of tractor operation.

Grease

Fittings

Figure 6-2

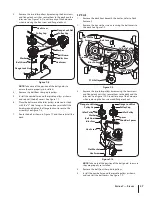

Pivot Points & Linkage

Lubricate all the pivot points on the drive system, parking brake

and lift linkage at least once a season with light oil.

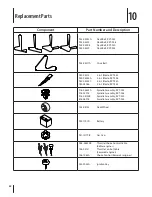

Summary of Contents for RZT S Series

Page 38: ...Notes 38 ...