Troubleshooting

8

13

Problem

Cause

Remedy

Loss of power

Spark plug wire loose.

1.

Vent in gas cap plugged.

2.

Firmly connect spark plug wire.

1.

Clear vent.

2.

Excessive vibration

Loose parts or damaged auger.

1.

Stop engine immediately and disconnect

1.

spark plug wire. Check for possible damage.

Tighten all bolts and nuts. Repair as needed.

If the problem persists, take snow thrower to

an authorized service dealer.

Snow thrower fails to self-

propel

Auger control cable out of adjustment.

1.

Auger drive belt loose or damaged.

2.

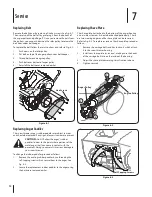

Adjust auger control cable as shown in

1.

Maintenance & Adjustments section.

Replace auger drive belt.

2.

Augers continue to rotate

Auger control cable out of adjustment.

1.

Adjust auger control cable as shown in

1.

Maintenance & Adjustments section.

Unit fails to discharge snow

Chute assembly clogged.

1.

Foreign object lodged in auger.

2.

Auger control cable out of adjustment.

3.

Auger belt loose or damaged.

4.

Stop engine and disconnect spark plug wire.

1.

Clean chute and inside of auger housing with

clean-out tool or stick.

Stop engine immediately and disconnect the

2.

spark plug wire. Remove object from auger.

Adjust auger control cable.

3.

Replace auger belt.

4.