4

- only handle with safety gloves

- do not touch the rope inlet

- slowly position the slack rope to the load

tHe WinCH

Do not exceed the capacity of each rope layer.

Before taking into operation, a compe tent

person must check:

- the lifting device

- the load bearing parts of the struc ture

- the carrying medium

- mounting

DaiLy exaMinationS

- brake functions

- condition of the rope and loading device

- load bearing parts of the structure.

- the load carrying medium

LoaD attaCHMent DeViCe

- check it has sufficient carrying capac ity

- load hooks must have safety catches

- load hooks must be secured to the rope with

a solid eye and high pres sure rope clamp and

tested according to the regulations

- fix the load correctly

- do not use the winch rope as a hitch ing

device.

the winch should be given a thor ough

examination by a com petent person at

least once a year.

always ensure the maintenance inter-

vals are adhered to.

only use original accessories and spare

parts; otherwise safe function is not

guaranteed.

teCHniCaL Data (see tab. 1)

funCtionaL DeSCRiPtion

The hand winches are drum winches with spur

gear. The load is automatically held by load

pres sure brake.

The winch housing is made of plated steel and

is suitable for mounting, especially onto walls,

masts and similar installations.

The bearing of the rope drum is through rolling

bearing respectively fric tion bearing.

Mounting inStRuCtionS

Mounting:

ATTENTION:

- The mounting structure must be de signed

to sustain the max. forces im posed by the

winch

- Pay attention that the mount ing surface is

flat and true

- Only fix the winch by means of good quality

screws

- Tighten the screws evenly

- Secure the screws

- Ensure that the crank is free running (crank

clearance)

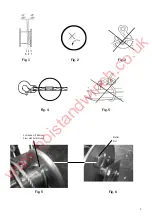

Wire rope fixing

Attention:

With wrong rope coiling the brake

is not effective.

Rope coiling has to accordingly the connection

of the winch. The winch should be turned

180° when installed with a downward going

rope descent direction.

Attention:

Pay to correct rope direction.

The fastening of the wire rope has to becarried

out as follows:

Move the screw with hole through a bore hole

in the side plate (see Fig. 6). Guide the end

of the wire rope through the hole in the screw.

From the outside adjust the nut (see Fig. 7)

and tighten the nut by hand force.

Attention:

For rope selection pay to the

technical data for the rope.

Calculate the rope length in such a way that at

least 3 full turns of rope remain on the drum

in lowest load position.

oPeRating inStRuCtionS

the winch must first be run with 50%

of the nominal load before operation.

Before operating the winch the drum must

have at least 3 rotations with 50 % of the

nominal load. The grease of the wormgearing

should be put back into the gearing by means

of a brush. After this operation the winch can

be put into full use.

At least

25 % of the nominal load

must be

on the winch as load for the proper working

of the friction brake.

Safety inStRuCtion

the winches are only suited for manual

operation.

- Lifting the load by turning the crank in

clockwise direction.

- Lowering the load by turning the crank in

counter-clockwise direction.

inSPeCtion- anD MaintenanCe

inStRuCtionS

Safety instruction

Before carrying out inspection and main-

tenance works (see Tab. 2) ensure the winch

is un loaded.

The working life of the winch is limited, wearing

parts have to be replaced in good time.

ReCoMMenDeD LuBRiCant

For all grease lubricating points:

Multipurpose grease acc. to DIN 51825

T1 K 2 K

Waste lubricant has to be disposed ac c. to

legal regulations!

oPeRating faiLuReS anD tHeiR

CauSeS (see tab. 3)

DiSPoSaL

After having placed out of service, the parts

of the hand winch have to be recycled or

disposed according to legal regulations!

www.hoistandwinch.co.uk