26

©

2019

Columbus McKinnon Industrial Products GmbH

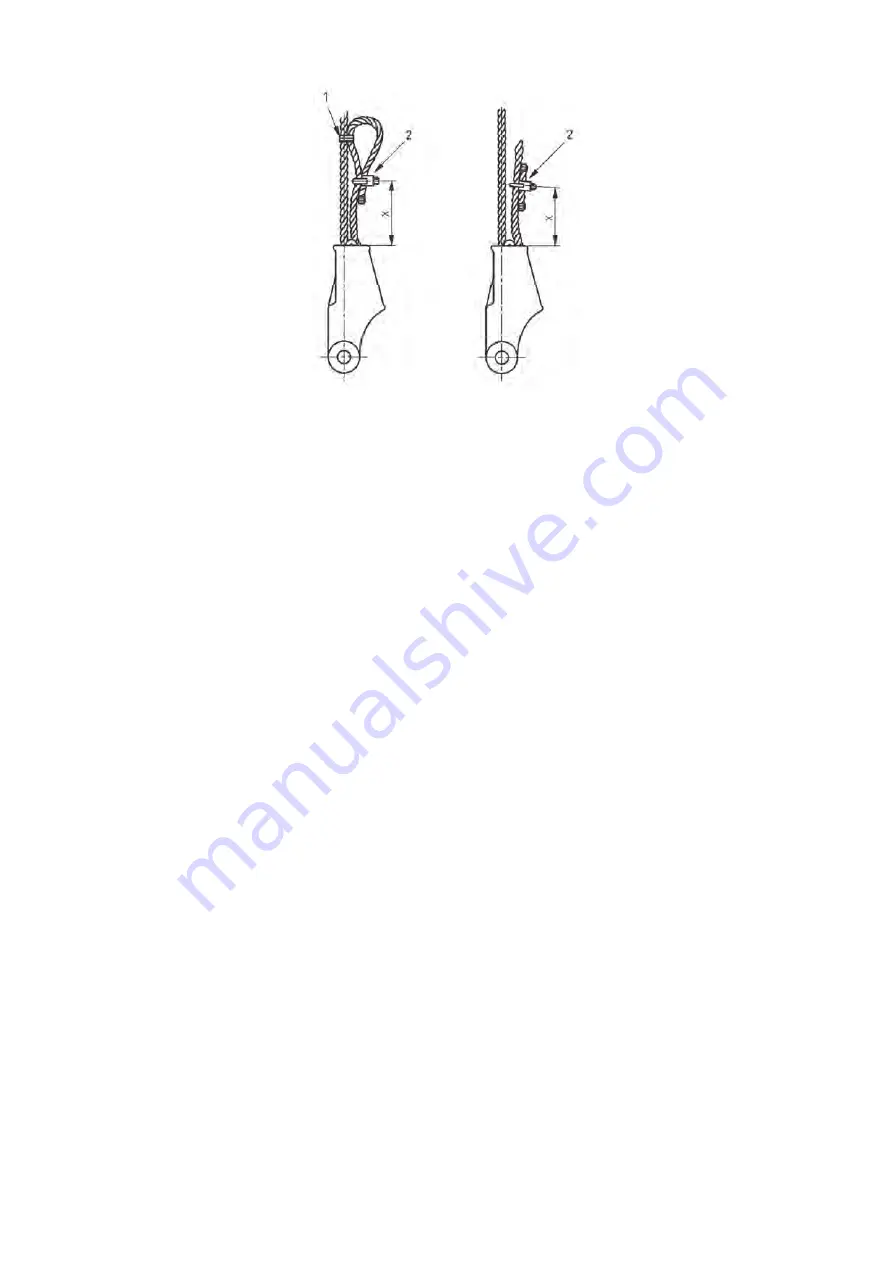

Note: Dimension X, as the distance of the clamp from the nearest part of the housing, should not exceed 75 % of the total length of the

wedge, to prevent the rope from being damaged if X is too small, or the wedge falling out of the housing if the rope is relaxed and X is

too large.

ATTENTION: The operating instructions of the manufacturer of a wedge end clamp must always be taken into account.

Lose rope-end

• The exiting rope must always be able to run out freely! The loose end of the rope must hang freely and must be able to untwist itself, or

be routed properly, so that loops may be avoided.

• To prevent the unloaded wire rope from being damaged, install a pulley or some other suitable rope guide!

ATTENTION: To prevent the unloaded wire rope from running on the edges and being damaged, install a pulley or some other

suitable rope guide!

Before operating the continuous winch, the following must be checked by a competent person through one or more test drives, and the

result must be recorded in writing:

• Does the rope run through the winch smoothly and the optionally available safety devices?

• Damaged ropes endanger work safety and must therefore be replaced immediately!

• Is the unit fastened to the suspension structure, the suspension, the working platform or basket properly?

• Are the control switches working (UP, DOWN, EMERGENCY STOP)?

• Upon releasing the UP or DOWN button, as well as on actuating the EMERGENCY STOP button, the load movement must stop

immediately.

• Is the upper EMERGENCY limit switch working?

For this, actuate the trigger manually during the upward movement. The load movement must be stopped immediately!

I

NSPECTION BEFORE INITIAL OPERATION

According to the existing national/international accident prevention or safety specifications, lifting units must be checked

• At least once per year by a competent person

• According to the risk assessment of the operating company,

• Before the initial start-up,

• Before restart following a shutdown

• After basic alterations.

Actual operating conditions (e.g. operation in galvanizing facilities) can dictate shorter inspection intervals.

The checks are essentially visual and functional, which should guarantee that the unit is in a safe condition and if necessary, faults and

damages caused by e.g. improper transport or storage, can be identified and remedied.

The condition of components with regard to damage, wear, corrosion or other changes must be assessed, and the completeness and

effectiveness of the safety devices must be determined.

Competent persons may be, for example, the maintenance engineers of the manufacturer or the supplier. However, the company may

also entrust the inspection to its own appropriately trained specialist personnel. The inspections have to be initiated by the operating

company.

Initial operation and recurring inspections must be documented (e.g. in the CMCO works certificate of compliance).

Paint damage should be touched up in order to avoid corrosion. All joints and sliding surfaces should be slightly lubricated. In case of

heavy contamination, the unit must be cleaned.

If the hoist is used as a crane, it has to be inspected and approved by a crane expert before initial operation. This inspection has to be

registered in the crane inspection book. The inspection by the crane expert has to be instigated by the operating company.

www.hoistandwinch.co.uk