23

©

2019

Columbus McKinnon Industrial Products GmbH

Single-phase alterning current: 230V (1P+N+PE) 50Hz with 16A Schukostecker

• A 4-core (3-phase device) or 3-core (1-phase device), insulated cable with a flexible braid (heavy rubber cable) must be used for the

mains connection. The earth wire must be longer than the current-carrying wires. The cross-section must be min. 1.5 mm² and the cable

length a maximum of 50 m.

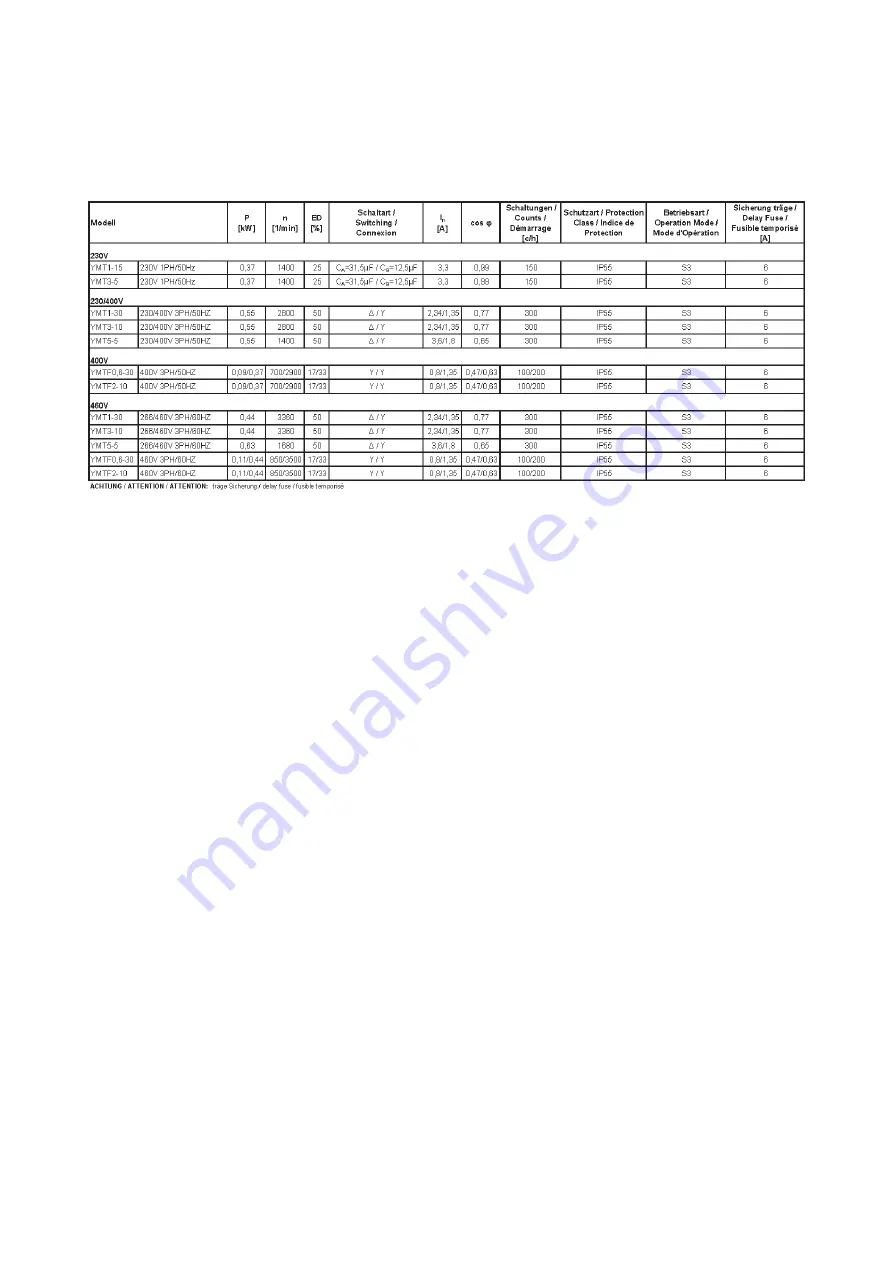

• Fuse protection for the different models are shown in the table.

• The ends of the cable must be fitted with wire end sleeves.

Wire rope installation

Attention: Always wear protection gloves for handling wire ropes.

• Use the original Yale wire ropes exclusively.

• Make sure that the wire rope has the correct diameter and an adequate length.

• Always uncoil the wire rope properly and without a spin (caused by the rotation with reel) Otherwise, the wire rope could get entangled

while being coiled/uncoiled on the drum and become unusable.

• Examine the condition of the wire rope:

- Cable eye/pressure grouting not damaged?

- For ropes with hooks: the fuse hatch is intact, hooks are not bent?

- Proper rope tip without visible damage along the entire length?

- Rope must always be mildly lubricated!

Use simple multi-purpose oil or grease for lubrication.

Molybdenum disulphide (MoS2) or PTFE containing lubricants are not to be used.

Inserting the rope:

- Connect the supply voltage.

- Install spring-kit assembly for limit switches (support-hook side)

Installation sequence: Mounting sleeve with cylinder pins (2x), spring and switching plate.

- Then the top of the supporting cable (2), is pushed through the opening of the rocker switch (5) from below into the device until,

between cable strip (1) and pulley (4), it touches the traction sheave (3). (The view from the motor side, left-hand side of the rocker

switch is shown in the illustration below)

By pressing the ON button and simultaneously pushing the support rope, the independent transporting of the support rope is achieved.

The support rope then runs through the opposite opening of the rocker switch, back out of the device.

If the cable does not run in, check whether the rope is in good condition and if the ON button has been pressed, and possibly change

the motor's direction of rotation (using phase inverter in the CEE plug).

- Install second spring-kit in reverse order:

Switch plate, spring and mounting sleeve with two cylinder pins. The mounting sleeve is fixed approximately 3 cm above the top of the

cable (hand tighten cylinder pins).

www.hoistandwinch.co.uk