25

©

2019

Columbus McKinnon Industrial Products GmbH

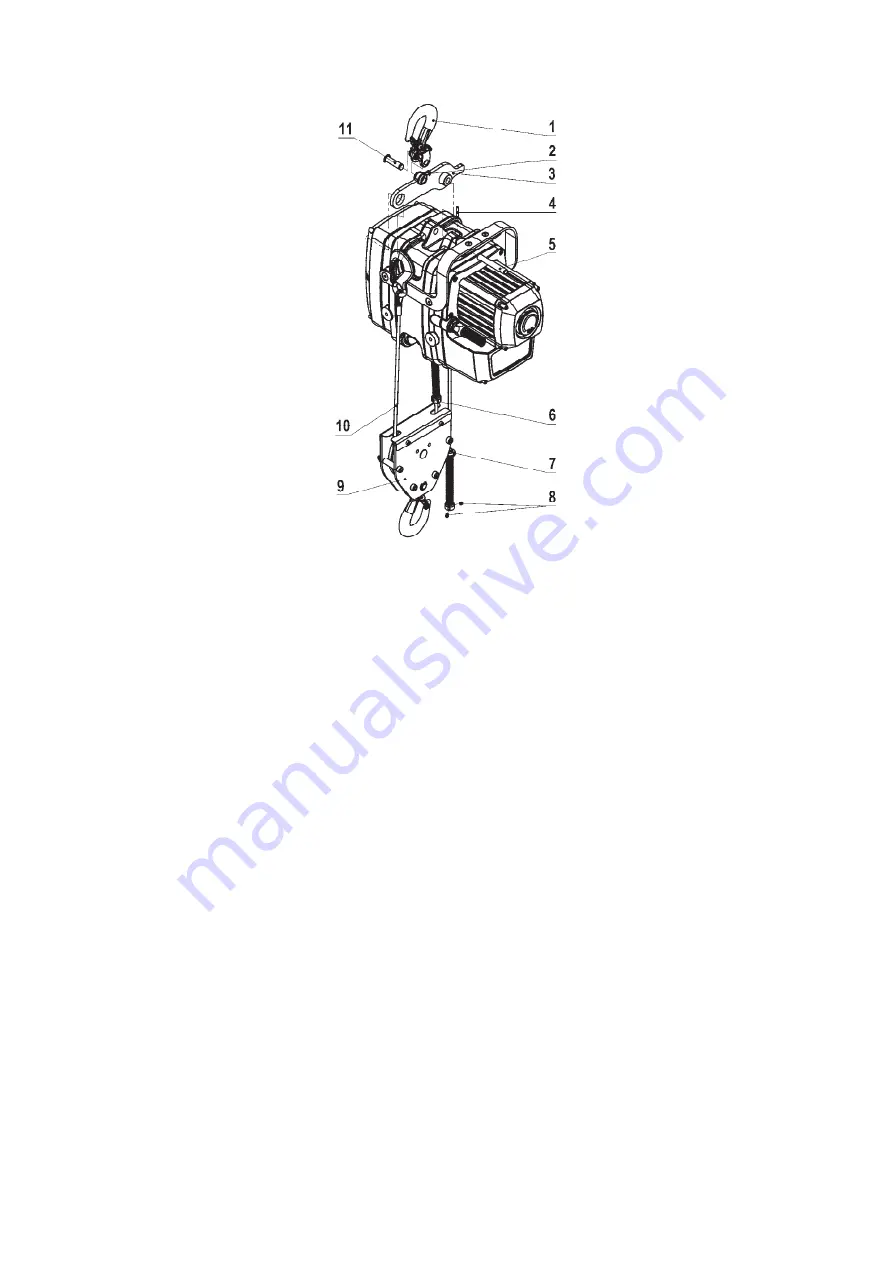

Assembling the second hooks for the pendulum stroke (optional)

As an option, a hook for the pendulum stroke can be mounted on the loose rope end with the aid of a wedge socket.

To do this, after the assembly of the wedge socket the eyelet hook (6) is attached to the wedge socket with the pin (5) and split pin (4).

Installation of a wedge socket (optional)

• Before assembling, check the parts for any signs of damage

• Only use wedge sockets with the appropriate dimensions and break load for the rope used.

• Components of different wedge sockets must not be used together

• If the wedge socket is shifted on the rope, the section of the rope that the clamp was in use on must no longer be in the load line and

must be separated, if necessary

• To install the rope and the wedge in the housing of the wedge socket, both rope ends must be under tension. The wedge should then

be driven in with a tool which does not damage the rope, the wedge and the housing.

Then the system must be loaded under supervision with a load of at least 10 % of the breaking load of the rope, so that the wedge and

rope settle in. The wedge must be seated accurately before the system is put into operation.

• The dead rope end must be secured so that the rope is prevented from pulling through during the creation of the rope connection and

the wedge cannot come loose during operation.

The following methods are recommended:

(a) The dead rope can be bent back to form a loop and secured by means of a wire rope clamp that has a U-shaped clamping bracket

according to EN 13411-5. The loop should be tightly bound to the load-bearing part of the rope with appropriate means such as soft

binding wire, to prevent the rope from protruding during operation.

(b) If there is the possibility that the loop in method a) bumps against an obstacle (for instance, a component in the operation), which

could loosen the wedge and make the rope pull through, the dead rope end should not be bent back, but placed parallel to the load-

bearing part of the rope. A spacer or a short rope end with the same diameter and a rope cable clamp with U-shaped clamp according

to EN 13411-5 are required to ensure that the rope is secured sufficiently. If necessary, the dead rope end can be bound tightly with soft

binding wire to the load-bearing section.

www.hoistandwinch.co.uk