15

15

Mtrac winch for passenger elevation

Platform runs on for

more than 20 cm af-

ter the DOWN button

has been released

S Brake defective/worn

a) Brake rotor worn

b) Air gap incorrectly adjusted

a) Have the winch repaired

b) Adjust air gap correctly

T Brake wet/aquaplaning

Make sure that the brake is dry (e.g. by

means of protective cover), only con-

tinue travelling if the brake works

Contact Yale Industrial Products or an authorised hoist service company, if the steps mentioned above do not result in clarifying and elimi-

nating the cause.

6. Maintenance

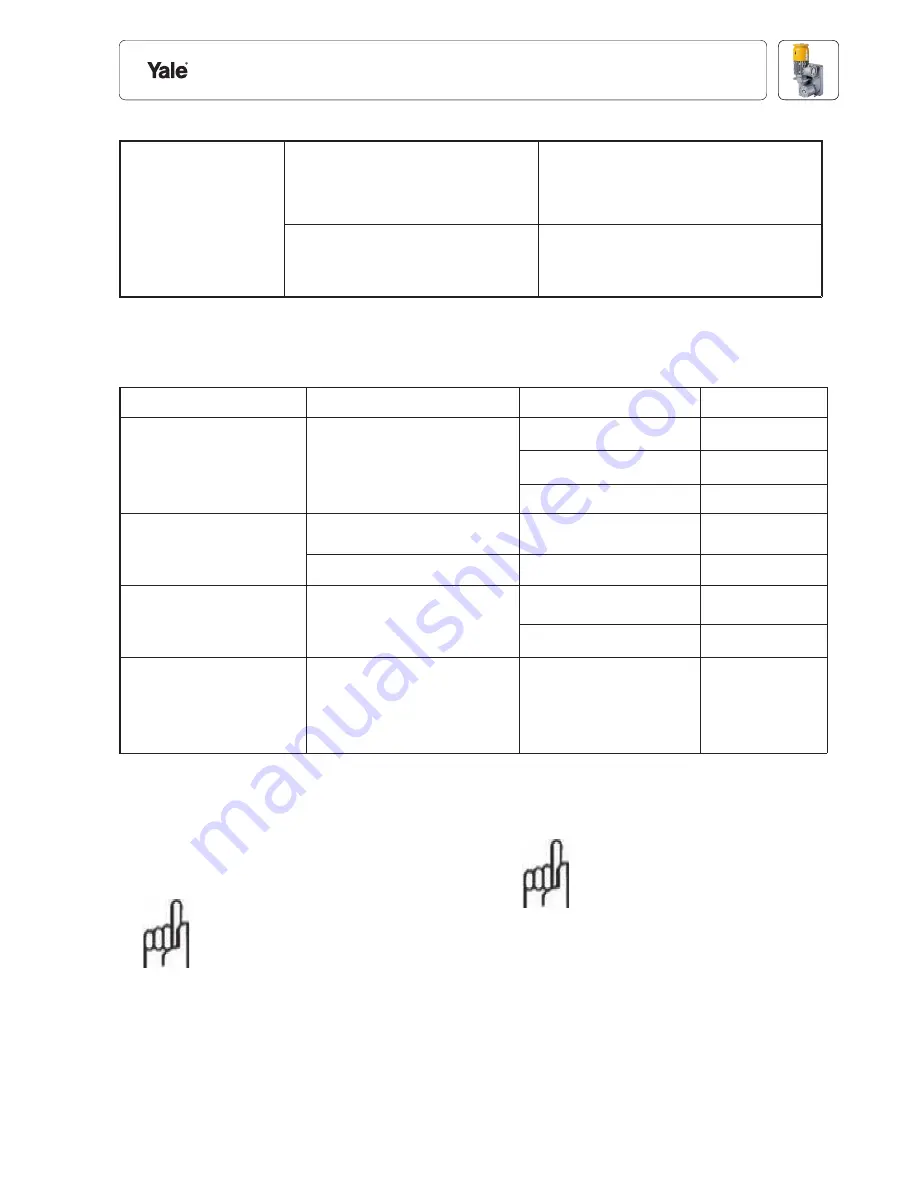

Date/performed by

Regulations

Item to be checked

Description

Each working day

by the

supervisor

DIN EN 1808

Safety requirements on Sus-

pended Access Equipment

Fastening parts

In section 4.2

Yale winch

In section 4.2

Yale safety lock

In section 4.2

Each week

by the

supervisor

DIN15020 sh. 2/ISO 4309

Wire ropes

In section 6.2 A

DIN EN 1808

Electrical cables

In section 6.2 A

Annually

by a

competent person

DIN EN 1808, BGV D8

(Winches, lifting and towing

devices)

Entire installation

Yale endless winch

In section 6.2 B

After 200 h (M2/1C

m

)

or 400 h (M3/1B

m

), at

the latest,

by

Yale Indus-

trial Products

EN14492-1,

BGV D8 (Winches, lifting and

towing devices)

General overhaul of the

Yale endless winch and

Yale safety lock

In section 6.2 B

Use common multi-purpose oil or grease for lubricating.

Do not use any lubricants which contain molybdenum

disulphide (MoS

2

) or PTFE!

C) Motor and motor brake

The electro-motor of the winch is maintenance-free.

Clean the motor cover if it is extremely dirty to make sure that the motor

is supplied with enough air.

The motor brake is maintenance-free; it must, however, be kept free of

oil and grease!

Only clean in the case of exceptional operation conditions and in the case

of strong dirt accumulation.

6.1 Maintenance and servicing

A) Rope drive and gearbox

Rope drive and gearbox are almost maintenance-free.

Lubricating the ropes on a regular basis provides the rope drive with

sufficient lubrication.

The service life of the rope drive is considerably increased

by lubrication. The traction of the rope is not affected by

proper lubrication.

B) Wire ropes

• Wire ropes must always be slightly lubricated. Ensure that they are

clean, i.e. do not deposit them on dusty ground or in dirty surroundings.

• Never use wire ropes to fix a load.

• Always wind and unwind the wire ropes properly on/from the reels.

• Never pull wire ropes over edges.

Summary of Contents for YaleMtrac

Page 18: ...18 18 Mtrac winch for passenger elevation...

Page 19: ...19 19 Mtrac winch for passenger elevation...

Page 20: ...20 20 Mtrac winch for passenger elevation...

Page 21: ...21 21 Mtrac winch for passenger elevation...

Page 22: ...22 22 Mtrac winch for passenger elevation...