16

16

Mtrac winch for passenger elevation

6.2 Regular checks

A) Ongoing checks

Before and during operation always make sure that all components

used, i.e.

• Yale endless winches

• Yale safety locks

• Yale wire ropes

• Rope return sheaves

• Sling gear, etc.

are correctly fitted and are free of detectable defects.

Stop working immediately if defects occur during opera-

tion.

All type and instruction plates must be fitted and legible. Any missing or no

longer legible type and instruction plates must be replaced immediately!

Wire ropes must be replaced immediately if a defect

according to DIN15020 sheet 2 or ISO4309 has been

detected during the weekly check:

– more than 11 broken wires over a length of 24 cm (dia. 8) / 27 cm

(dia. 9) / 30 cm (dia. 10)

– Strong formation of rust on the surface or inside

– Heat damage, indicated by burning discoloration

– Reduction of the outer diameter to less than 7.6 mm (dia. 8 mm) /

8.5 mm (dia. 9 mm) / 9.4 mm (dia. 10 mm)

If damage is detected on the insulation or on the cable connections during

the weekly check of the electrical cables, replace or repair supply and

control cables immediately!

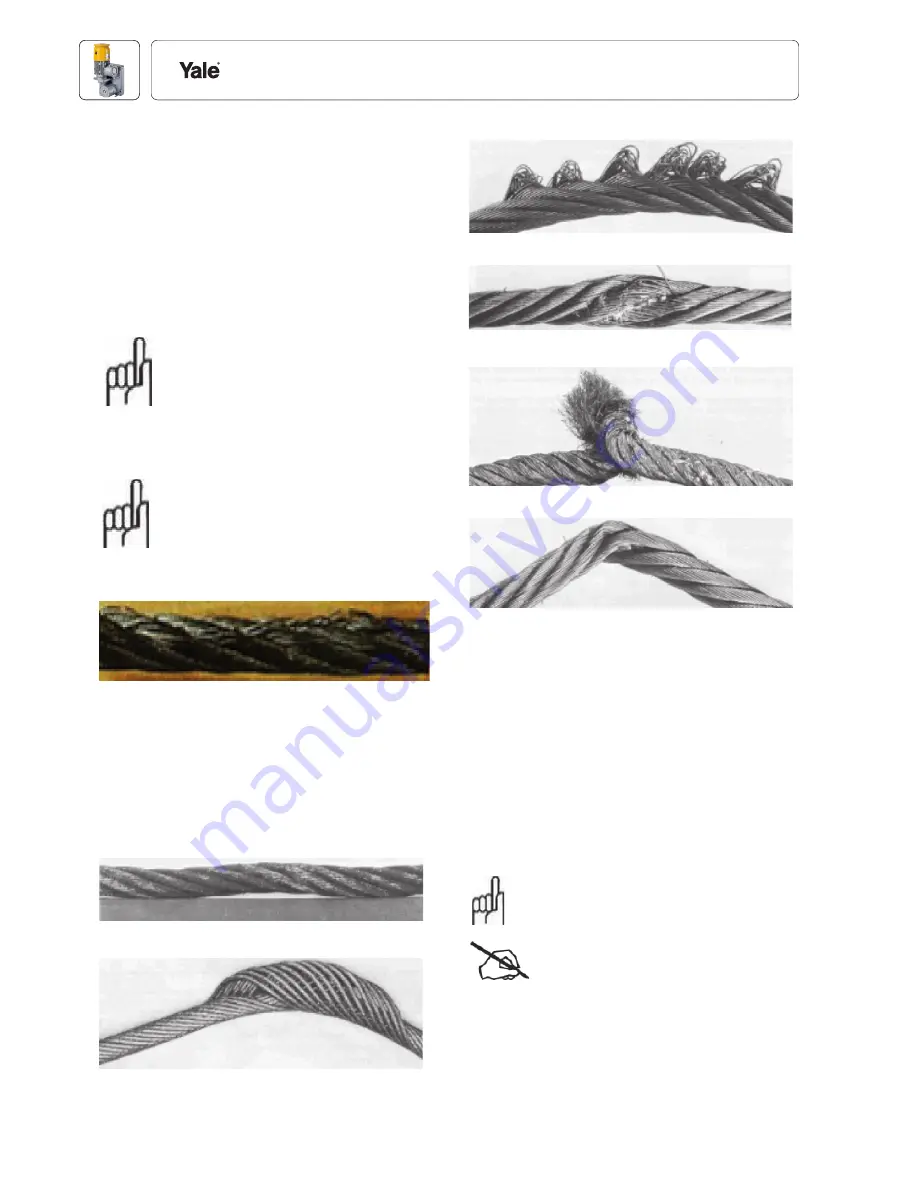

Excerpt from DIN15020: Illustration of the most common types of outer

damage of wire ropes:

Figure 1: Wire rope with corkscrew-like deformation

Figure 2: Wire rope with bird-caging

Figure 3: Wire rope with wire loops

Figure 4: Wire rope with flattening caused by being run over

Figure 5: Wire rope with kink

Figure 6: Wire rope with bend

B) Safety check by a competent person

A

competent person

has been enabled to carry out

safety checks

on

Yale winches for passenger elevation and Yale safety locks by adequate

training at the manufacturer’s.

Safety checks of Yale winches for passenger elevation and Yale safety

locks must be carried out at least once a year by a competent person.

Exceptional ambient conditions or conditions of operation may require

additional safety checks according to the relevant accident prevention regu-

lations for “Hoists, lifting and towing devices” (BGV D8) and the standard

“Safety requirements on Suspended Access Equipment” (DIN EN1808).

Yale winches for passenger elevation with M2/1C

m

group of mechanisms

must be subjected to a general overhaul after

200 hours of operation

at the latest and Yale winches with M3/1B

m

group of mechanisms after

400 hours of operation

at the latest by the manufacturer.

If a

catching operation

has occurred with a Yale safety lock,

the Yale safety lock, fastening and safety rope must be

checked by a

competent person

within the framework of an

extraordinary safety inspection.

All results of the annual and extraordinary inspections

must be entered into a log booklet.

This is the responsibility of the operating company.

6.3 Repairs of the winch

Any repairs on Yale winches and Yale safety locks must only be carried

out by Yale Industrial Products or a hoist service company authorised by

Yale; only original spare parts must be used for repairs. Only use gear oil

type Mobil SHC 632 for refilling or for changing the gear oil!

Summary of Contents for YaleMtrac

Page 18: ...18 18 Mtrac winch for passenger elevation...

Page 19: ...19 19 Mtrac winch for passenger elevation...

Page 20: ...20 20 Mtrac winch for passenger elevation...

Page 21: ...21 21 Mtrac winch for passenger elevation...

Page 22: ...22 22 Mtrac winch for passenger elevation...