11

11

MACHINE PREPARATION

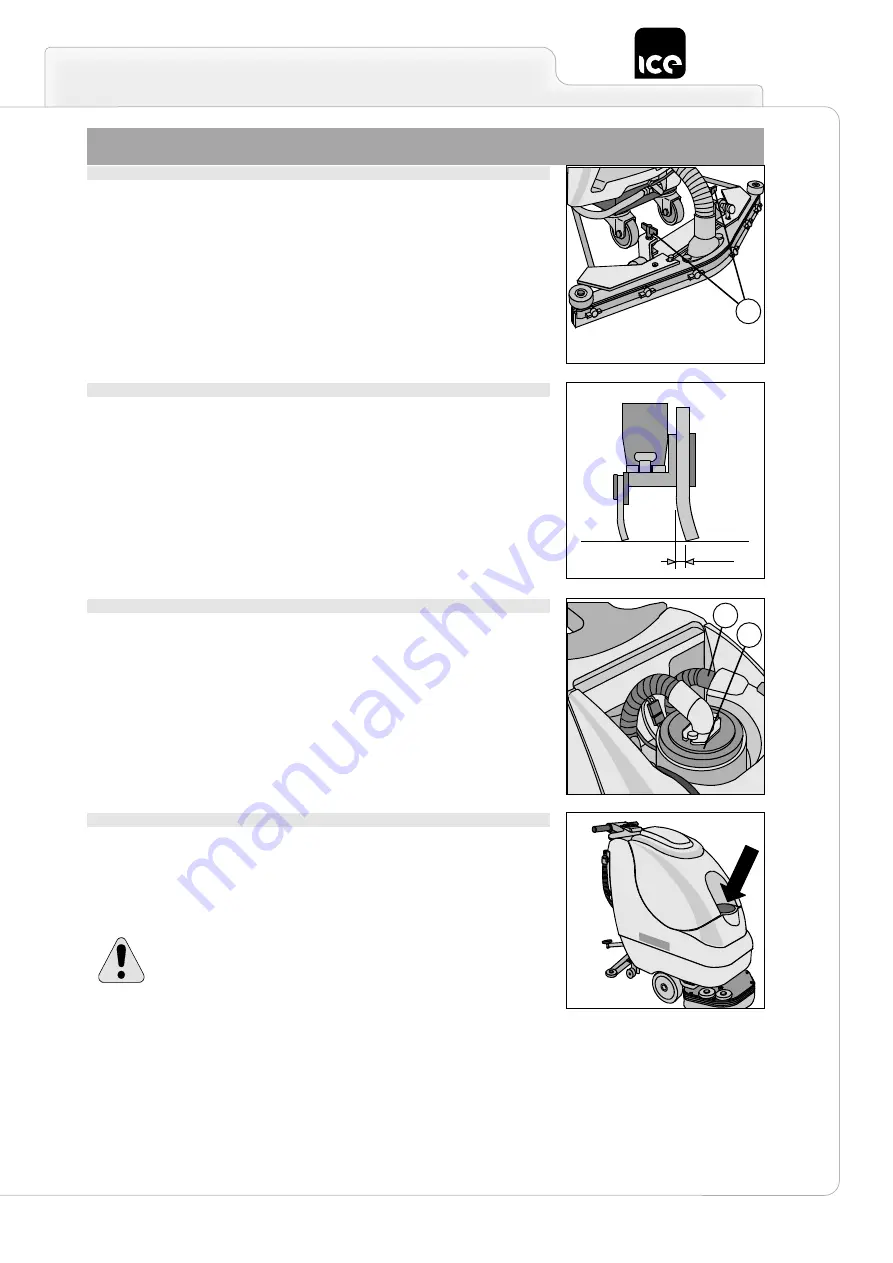

ADJUSTING THE SQUEEGEE HEIGHT

The height of the squeegee must be adjusted on the basis of the state of wear and tear

of the rubber. To do this, turn the wing nuts (1) anticlockwise to raise the squeegee,

and clockwise to lower it.

Remarks: the right and left wheels must be adjusted to the same level, so the

squeegee can work parallel to the floor.

1

ADJUSTING THE SQUEEGEE INCLINATION

During working operation, the rear rubber is tilted slightly backwards (by about 5mm) in

a uniform way for its whole length. If it is necessary to increase the bend of the rubber

in the central part, you must tilt the squeegee backwards, rotating the adjuster (1)

anticlockwise. To increase the bend of the rubber at the sides of the squeegee, rotate

the adjuster clockwise. When fully adjusted, fix the lock nut.

5mm

RECOVERY TANK

Open the cover and check the suction cap (2) is correctly blocked (insert the notches in

their housings, rotating the cap clockwise) and correctly connected to the tube leading

to the suction motor.

In addition, check the squeegee tube (1) is correctly inserted in its housing, and that

the drainage tube cap (in the rear part of the machine) is closed.

1

2

DETERGENT SOLUTION

Fill the solution tank with clean water at a temperature no greater than 50°C and add

liquid detergent in the proper concentration, following the instructions of the

manufacturer. The formation of excess foam could damage the suction motor, so use

only the minimum amount of detergent necessary. Reassemble the cap.

WARNING!

always use low foam detergent. To avoid the production of

foam, before starting to clean, put a minimum quantity of antifoam

liquid into the recovery tank.

Never use pure acid.

Summary of Contents for SCRUB 45D

Page 23: ......