13

MACHINE PREPARATION

ATTENTION: in order not to cause permanent damage to the batteries it is

essential to avoid their complete discharge: arrange the recharge within a few

minutes of the switching on of the flashing "discharged batteries" signal

ATTENTION: never leave the batteries completely discharged, even if the

machine is not being used

ATTENTION: for the daily recharging of the batteries, you must fully respect

the indications provided by the manufacturer or retailer. All installation and

maintenance operations must be carried out by expert personnel, trained at the

COMAC assistance centre

WARNING Make sure that the battery charger green LED is on before using

the machine again

ATTENTION: danger of exhalation of gas and leakage of corrosive liquids

ATTENTION: danger of fire: do not go near with free flames

10.

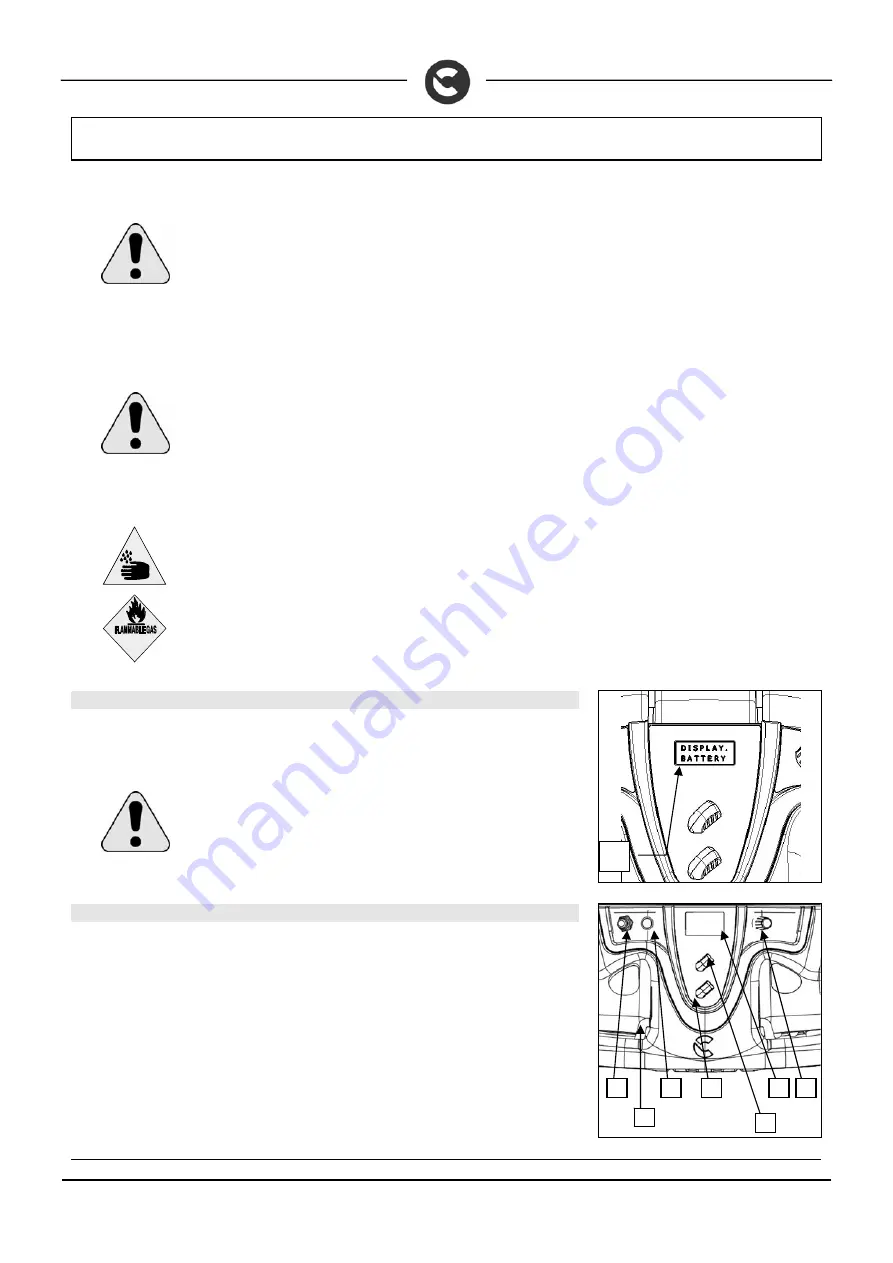

BATTERY INDICATOR (FOR B-BT VERSIONS ONLY)

On the instrument panel of the machine there is a monitor (1) indicating (amongst other things) the

battery charge status. If the upper line contains 8 light indicators, the battery charge level is 100%. If

the edges of the indicators are flashing, this means the batteries are run down.

ATTENTION: a few seconds after the last indicator on the monitor has flashed,

the brush motor will automatically switch off. With the remaining charge it is

possible to complete the drying process before recharging

11. INSTRUMENT PANEL COMPONENTS

The instrument panel components are identified as follows:

1.

Levers to activate brushes/traction (located beneath the grip)

2.

Water output adjustment switch (for CDS system only)

3.

Detergent output adjustment switch (for CDS system only)

4.

Battery level / hour-counter display

5.

Battery level hour-counter display command button

6.

Speed level knob (for automatic traction version only)

7.

Brush uncoupling command button (for battery system only)

1

5

1

3

2

6

4

7