26

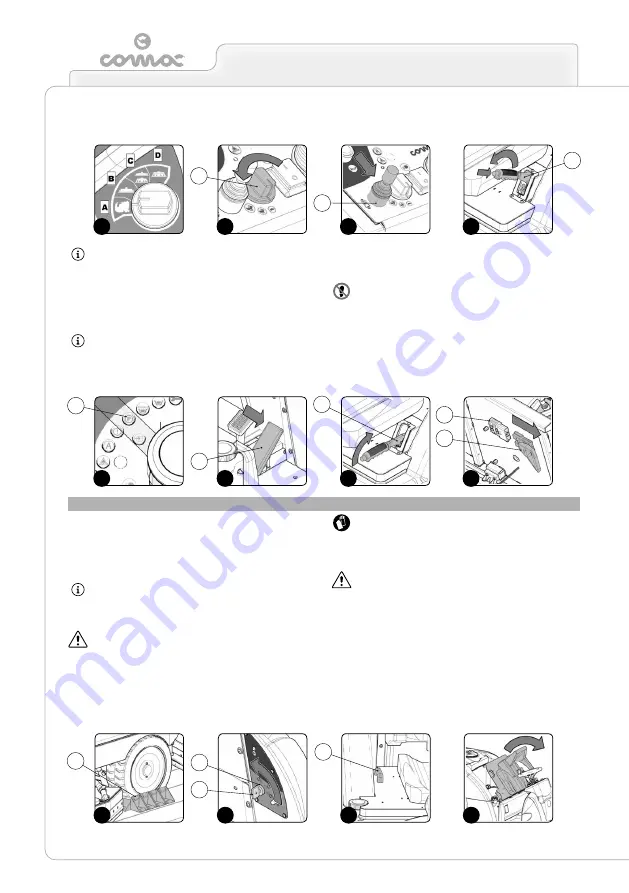

12. Select the speed level “step-01” and turn the knob (8) anti-

clockwise until it reaches the bottom of the scale (

Fig.10

).

13. Shift the direction lever (9) to “reverse”, moving it in the direction

shown by the arrow (

Fig.11

).

14. Release the parking brake by moving the parking brake lever

(10) (at the side of the operator seat) in the direction shown by

the arrow (

Fig.12

).

ATTENTION:

the indicator light (11) relating to the parking

brake will be deactivated on the control panel (

Fig.13

).

15. Press the drive pedal (12) to begin moving the machine (

Fig.14

).

16. Drive the machine down the ramp.

17. Engage the parking brake by moving the parking brake lever

(10) (at the side of the operator seat) in the direction shown by

the arrow (

Fig.15

).

ATTENTION:

the indicator light (11) relating to the parking

brake will be activated on the control panel (

Fig.13

).

18.

Bring the main switch (1) to "0", turning the key (2) a quarter turn

to the right (

Fig.2

). Remove the key from the main switch.

19. Get off the machine.

ATTENTION:

do not position your foot above the brush head

while the machine is coming down the ramp.

20. Grip the handle (4) and raise the seat mounting plate to the

maintenance position (

Fig.3

).

21. Disconnect the buffer battery carriage connector (5) from the

main system connector (6) of the machine (

Fig.16

).

22. Grip the handle (4) and lower the seat mounting plate to the

working position (

Fig.8

).

TAKING THE MACHINE OUT OF ITS PACKAGING (G VERSIONS)

The machine is shipped in specific packaging. To remove it,

proceed as follows:

1. Bring the pack to a covered but well-aired area.

2. Place the lower part of the outer packaging in contact with

the floor.

ATTENTION:

use the pictograms printed on the box as a

reference.

3. Remove the outer package.

ATTENTION:

as the packaging elements (plastic bags,

staples, etc.) are a potential source of danger, they should not

be left within the reach of children, disabled persons, etc.

4. Remove the boxes containing the disc brushes and squeegee

from the machine.

ATTENTION:

these operations must be carried out using

protective gloves to avoid any possible contact with the

edges or tips of metal objects.

5. Insert a ramp in the rear part of the machine.

ATTENTION:

the ramp gradient must not be such as to cause

damage to the machine as it comes down.

6.

The machine is fixed to the pallet with wedges (1) that block the

wheels (

Fig.1

). Remove these wedges.

7. Check the main switch (2) on the control panel is in the “0”

position. If this is not the case, turn the key (3) a quarter of a turn

to the left (

Fig.2

). Remove the key from the main switch.

8. Grip the handle (4) at the side of the seat (

Fig.3

), and raise the

seat mounting plate to the maintenance position (

Fig.4

).

11

12

10

9

15

16

14

13

11

12

10

5

6

9

10

8

3

4

2

1

1

3

2

4

Summary of Contents for ULTRA 120 B-G

Page 2: ......

Page 7: ...7 36 72 102 6 9 10 110 107 106 75 5 76 74 58 7 59 7...

Page 9: ...9 103 4 56 31 43 109 15 3 98 22 65 24 108 19 34 35 23 68 44 63 64 99...

Page 10: ...10 2 94 17 101 96 105 69 12 11 18 73 40 97 95 104 42...

Page 68: ...68 NOTES...

Page 69: ...69 NOTES...

Page 70: ...70 NOTES...

Page 71: ......