36

DAILY MAINTENANCE

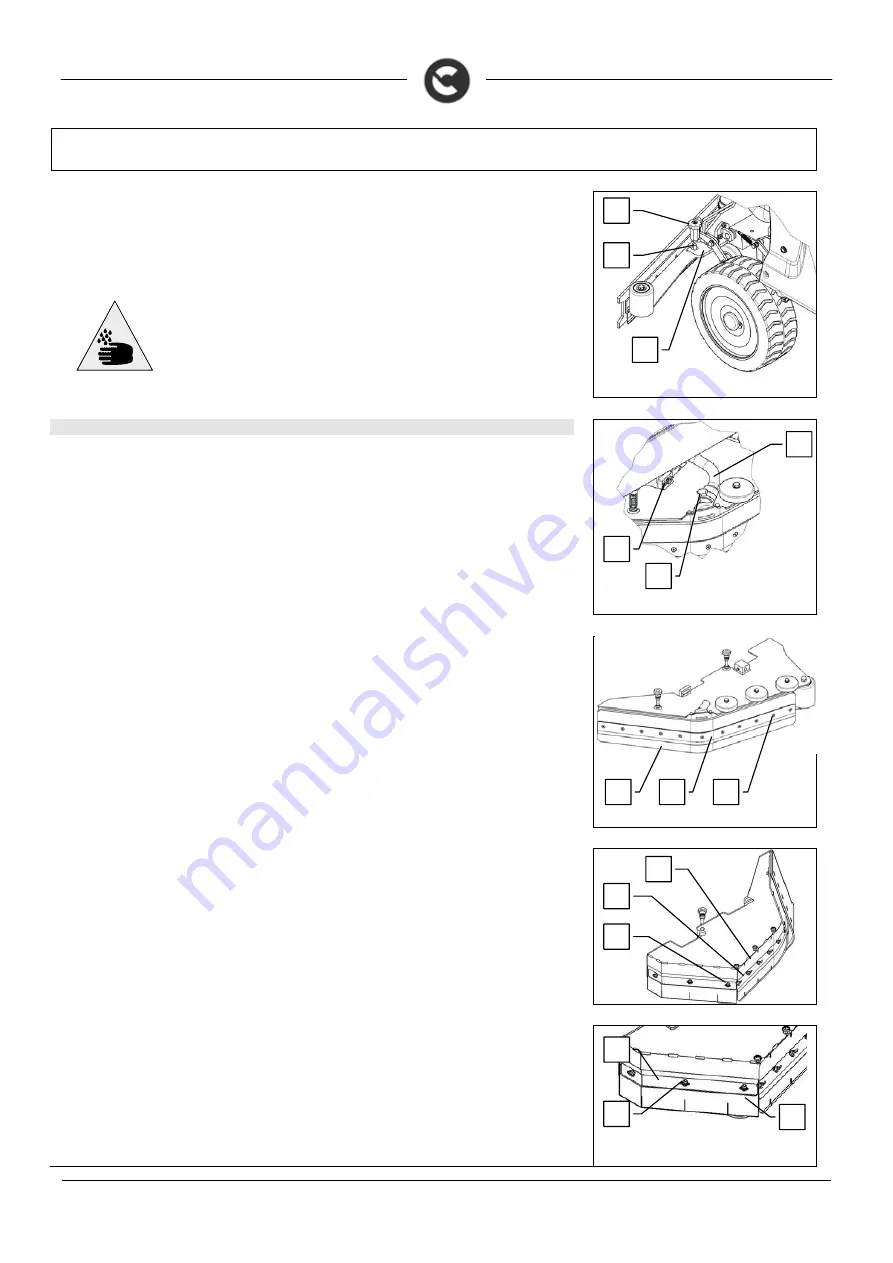

After cleaning, replace the squeegee on its support:

1.

Insert the squeegee right-hand pin (1) into the right-hand slot of the squeegee support (2), secure it

by means of the handwheel (3).

2.

Insert the squeegee left-hand pin into the left-hand slot of the squeegee support, secure it by means

of the handwheel.

3.

Finally, insert the squeegee hose in its sleeve and secure it using the clamp.

ATTENTION: These operations must be carried out using gloves to protect

against contact with dangerous solutions

38. CLEANING THE BRUSH HEAD COVER

Careful cleaning of the whole suction unit inside the brush head cover ensures better cleaning and drying

of the floor as well as a longer suction motor life. Proceed as follows for cleaning:

1.

Ensure that the electrical system connector is disconnected from the battery connector

2.

Ensure the main switch key is set to “0”

3.

Ensure the parking brake is engaged

4.

Undo the mounting clamp (1) and remove the suction hose (2) from the brush head cover sleeve

5.

Remove the cover from the brush head unit by extracting the split pins (3)

6.

Clean the brush head cover and the rubbers thoroughly with a jet of water

Check the state of wear of the rear rubber. If the edge of the rubber is ruined, the rear rubber can be

turned on all four corners. If the rubbers are completely worn, replace them.

To remove the outer rubber:

1.

Undo the rubber-pressing blade securing nuts (7)

2.

Remove the rubber-pressing blade (8) and then the rubber (9)

3.

Undo the rubber-pressing blade securing screws (4)

4.

Remove the rubber-pressing blade (5) and then the rubber (6) to turn it over or replace it

5.

To replace the rubber, proceed in reverse order

Check the state of wear of the central rubber. If the edge of the rubber is badly damaged, the central

rubber can be turned on all four edges. If the rubbers are completely worn, replace them.

To remove the inner rubber:

1.

Undo the rubber-pressing blade securing nuts (7)

2.

Remove the rubber-pressing blade (8) and then the rubber (9) to turn it over or replace it

3.

To replace the rubber, proceed in reverse order

Check the state of wear of the front rubber. If the edge of the rubber is badly damaged, the front rubber

can be turned on two sides. If the rubbers are completely worn, replace them. To remove the rubber:

1.

Undo the rubber-pressing blade securing nuts (10)

2.

Remove the rubber-pressing blade (11) and then the rubber (12) to turn it over or replace it

3.

To replace the rubber, proceed in reverse order

3

1

2

3

2

1

6

5

4

7

8

9

10

11

12