Omega II

®

Installation, Operation & Maintenance

Combustion Research Corporation

Page 19

COMBUSTION AIR SUPPLY

NOTICE

Air that is not contaminated must be ducted to the

heater if chlorinated or fluorinated contaminants, high

humidity, other contaminants, or if negative pressure is

present in the area where the heater is installed.

1. Combustion air is a factory preset opening.

2. It is recommended that outside combustion air be used.

However, combustion air may be drawn from any space,

including the space that is being heated, PROVIDED

the building does not have a negative pressure and the

atmosphere is not contaminated with acid fumes,

fluorocarbons, corrosive substances, dirt, oil, etc., which

would have an adverse effect on the blower and radiant

tubing. DO NOT draw combustion air be drawn from an

attic space.

3. If outside air combustion air is not used and the room in

which the heater is used is of a tight construction,

provisions must be made for supplying combustion air.

One square inch of free area opening for each 5,000

Btu/hr input is required to replenish the air used by the

heating system.

OUTSIDE AIR SUPPLY (RECOMMENDED)

1.

The outside air intake assembly (PN 0314.00) consists

of: 1 - 4" OD inlet hood, I - 4" OD 24" long inlet flex and

2 clamps.

2.

The assembly may be extended by adding up to 20' of

the appropriately sized ducting. A maximum of two

elbows may be used. Insulating the ducting will stop

condensation from forming on its exterior.

3.

Air intake may be made through the roof using

"mushroom" type vent cap.

4.

Maintain a minimum of six (6') between the exhaust port

and the fresh air inlet port.

5.

Maintain a minimum of six inches (6") the inlet hood and

the exterior wall.

6.

DO NOT DRAW COMBUSTION AIR FROM ATTIC OR

SIMILAR SPACE. DO NOT USE PLASTIC TYPE

"DRYER" FLEX FOR THE COMBUSTION AIR INLET

FLEX.

7.

The air intake terminal must be located not less than

one foot (1') above grade.

NOTE

– Avoid installing inlet flex as an elbow into the

blower and DO NOT install inlet flex as an elbow into the

blower on burners with inputs of 155,000 Btu/hr and higher

- system pulsation can occur.

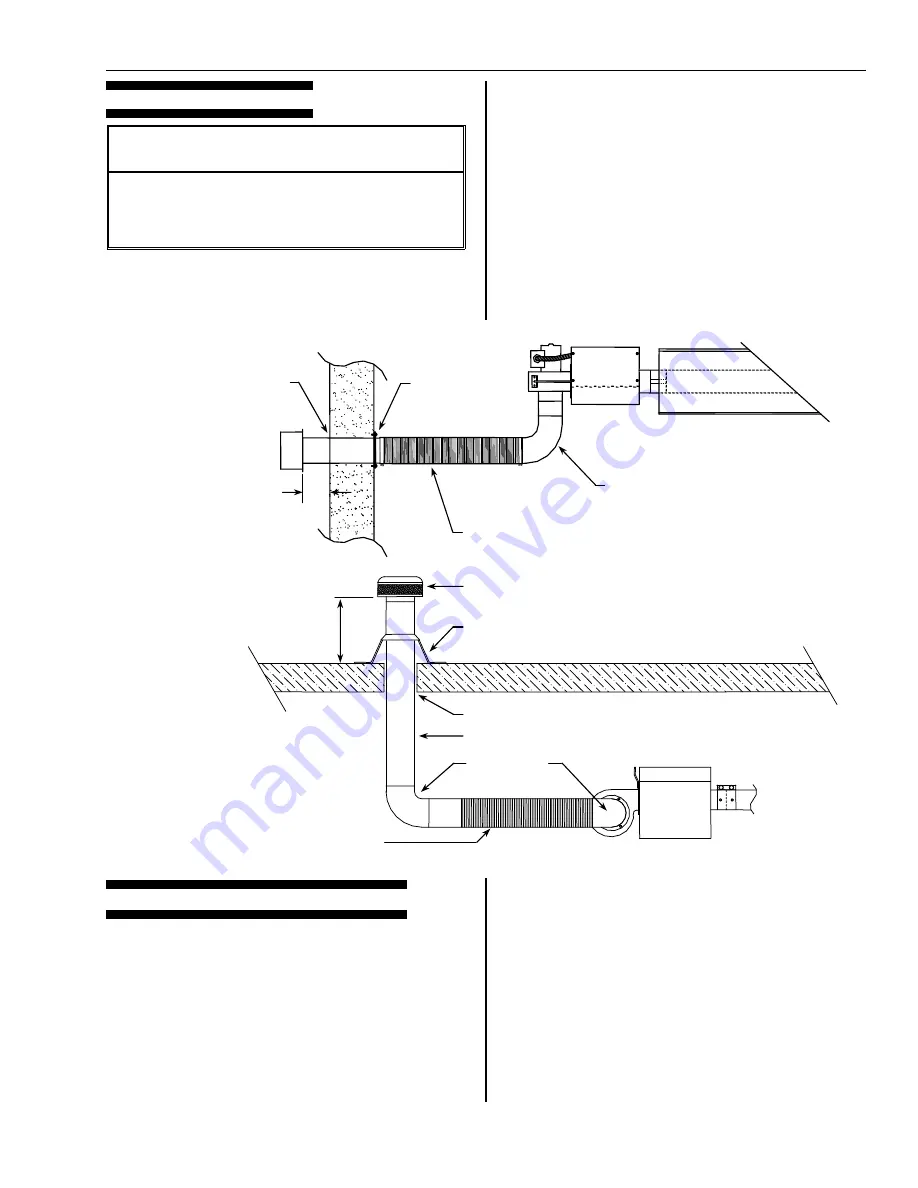

ROOF

PENITRATION

(SIDE VIEW)

No clearance required

4” Combustion air duct by installer

4” Elbow by

installer

Roof flashing

Min. 4” Inlet cap

Min. 2’

4” Flex

SIDE WALL

PENITRATION

(TOP VIEW)

Concrete nails

or screws

4 places

Install 4” dia. Inlet flex

nearest wall

Use 4” sheet metal of PVC

extension and elbow on inlet

to blower

Min. 6”

Caulk

Summary of Contents for Omega II

Page 40: ...Omega II Installation Operation Maintenance Page 36 Combustion Research Corporation...

Page 48: ......

Page 49: ......